NIOSH Conformity Assessment Notice

NIOSH CA 2018-1002

June 2018

1 – Summary

The National Personal Protective Technology Laboratory (NPPTL), a Division of the National Institute for Occupational Safety and Health (NIOSH), is responsible for the approval of respiratory protective devices in accordance with the regulations contained in Title 42 of the Code of Federal Regulations, Part 84 (42 CFR 84).

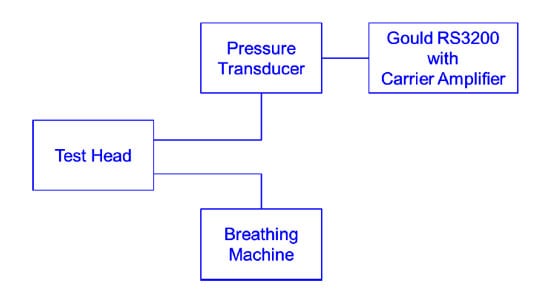

For more than 15 years, NPPTL has tested Respiratory Protective Devices (RPDs) using the Gould Instrument Systems, Inc. model RS3200 strip chart recorder (with carrier amplifier). Gould Instrument Systems, Inc. is no longer in business and replacement parts for the RS3200 are no longer available. This warranted the development of a new test system to replace the Gould RS3200 strip chart recorder.

To address this concern, NPPTL, under a contract with Data Science Automation (DSA), developed a personal computer (PC) based system running Microsoft Windows and using National Instruments’ LabVIEW™ data acquisition software. Data acquisition and carrier amplifier hardware were also incorporated into the new system.

NPPTL’s laboratories in Pittsburgh, Pennsylvania and Morgantown, West Virginia are equipped with the new LabVIEW™ based system. Only the Pittsburgh laboratory has the Gould RS3200 system. To validate the LabVIEW™ based system, testing was conducted in Pittsburgh and Morgantown using NIOSH-approved self-contained breathing apparatus (SCBAs). All units were tested using the Gould system in Pittsburgh as well as the LabVIEW™ systems in Pittsburgh and Morgantown. A statistician at NPPTL analyzed the results.

Results show that the LabVIEW™ strip chart system is capable of replacing the Gould strip chart recorder. Additional benefits of the LabVIEW™ system include automatic data logging and a reduction of the subjectivity associated with determining pass/fail results (using the strip recorder).

2 – Authority

42 C.F.R. Part 84, Respiratory Protective Devices

Subpart H, Self-contained breathing apparatus

Eight NIOSH Standard Test Procedures utilize the Gould RS3200 strip chart recorder:

- RCT-APR-STP-0065, Determination of Airflow Resistance of Breath Responsive, Powered Air-Purifying Respirators (PAPRs)

- RCT-ASR-STP-0105A, Determination of Airflow-Demand and Pressure-Demand, Type C and CE, Supplied-Air Respirators

- RCT-ASR-STP-0106, Determination of Inhalation Airflow Resistance, Pressure-Demand, Type C and CE, Supplied-Air Respirators

- RCT-ASR-STP-0117, Determination of Positive Pressure, Closed-Circuit, Pressure-Demand, Self-Contained Breathing Apparatus

- RCT-ASR-STP-0120, Determination of Positive Pressure, Open-Circuit, Pressure-Demand, Self-Contained Breathing Apparatus

- RCT-ASR-STP-0121, Determination of Rated Service Time, Open-Circuit, Demand and Pressure-Demand, Self-Contained Breathing Apparatus

- RCT-ASR-STP-0135, Determination of Inhalation and Exhalation Breathing Resistance, Closed-Circuit, Demand and Pressure-Demand, Self-Contained Breathing Apparatus

- RCT-ASR-STP-0138, Determination of Safety Relief Valve Operation, Closed-Circuit, Demand and Pressure-Demand, Self-Contained Breathing Apparatus

3 – Background and Supplemental Information – Intra-Laboratory Comparison

Gould Instrument Systems, Inc. is no longer in business, which prompted the question “What do we do when our RS3200 strip recorder stops working?” To address this concern, as well as NPPTL’s goal of updating test procedures to take advantage of new or emerging technology, NPPTL began development of a new test system that could replace the Gould test system. NPPTL awarded a contract to Data Science Automation (DSA) for development of a PC based system using National Instrument’s LabVIEW™ data acquisition software and LabVIEW™ compatible data acquisition hardware. Additional carrier amplifier hardware was also necessary. This new system was developed for a Microsoft Windows operating system.

4 – References

Approval of Respiratory Protective Devices, 42 C.F.R, Part 84

December 7, 2017 NIOSH NPPTL Meeting for All Respirator Manufacturers