Mining Topic: Respiratory Diseases

What is the health and safety problem?

Miners are at risk of developing a lung disease called pneumoconiosis because of their exposure to airborne respirable dust. This type of dust includes extra fine particles that people can inhale into their lung tissue. Miners can also have an increased risk of dying from lung cancer. Risk increases when miners experience exposure to exhaust from diesel engines for five or more years.

Pneumoconioses (meaning dusty lung) can cause impairment, disability and premature death. The two main types of pneumoconioses that affect miners are coal workers’ pneumoconiosis (CWP) and silicosis. CWP, commonly called black lung, affects workers in coal mining. Silicosis can affect workers in many types of mines and quarries, including coal mines. Medical treatment cannot cure these diseases, so preventing them – through controlling respirable dust exposure – is essential.

Exposure to exhaust from diesel engines has the potential to produce symptoms typical of asthma. Diesel exhaust exposure may also contribute to other respiratory symptoms. Symptoms include irritation of the nose, inflammatory changes in airways, and lung function decline.

Other respiratory diseases, such as chronic obstructive pulmonary disease (COPD), may also occur in miners. These diseases can occur alone or in addition to pneumoconiosis.

What is the extent of the problem?

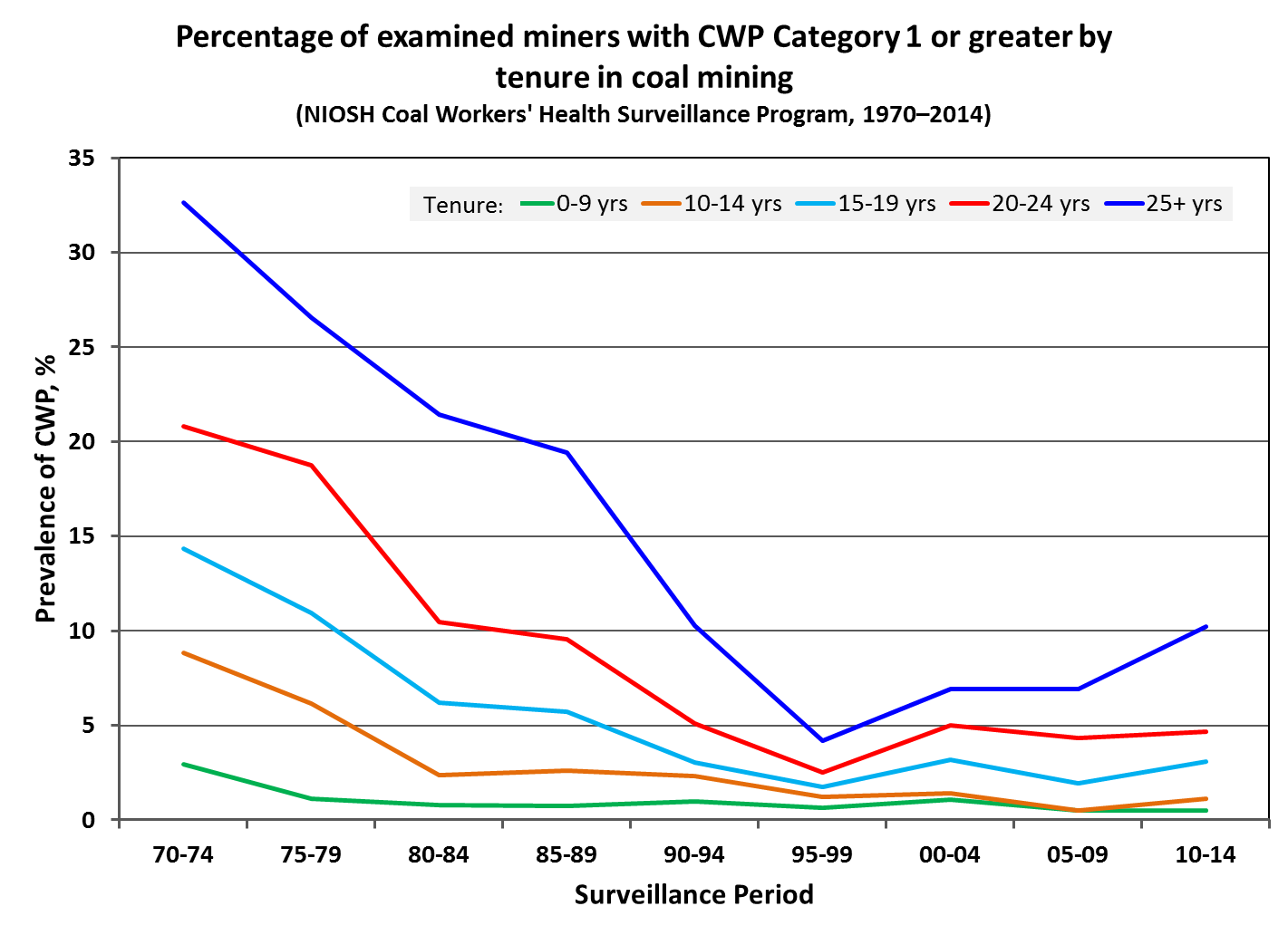

The Respiratory Health Division of NIOSH manages the Coal Workers’ Health Surveillance Program (CWHSP). This program provides coal miners an opportunity to have a chest x-ray about every five years throughout their careers. Since 1970, NIOSH has compiled data on the prevalence of CWP in underground coal miners. The graph shows a summary of this data. In the early 1970s, the prevalence of CWP was 33% among miners working 25 or more years. The prevalence dropped to less than 5% by the late 1990s. However, since that time, CWP prevalence has increased to more than 10% for these longest tenured miners. Progressive massive fibrosis (PMF) is the most severe form of CWP. For miners examined at three black lung clinics in Virginia, NIOSH reported 416 diagnosed with PMF, an unprecedented number. Through a special CWHSP program, NIOSH examined more than 2,200 surface miners from 2010-2011. Results of the scans found CWP in 46 miners, 12 of which had PMF.

Graph of CWP respiratory disease in miners. (Click for larger image.)

From 2007 through 2016, CWP was the underlying or contributing cause of death for 4,118 miners. From 1970 through 2016, CWP was the underlying or contributing cause of death for a total of 75,178 miners. The Black Lung Benefits Act is a federal program that pays compensation and medical expenses for miners disabled with CWP. From 1971 through 2019, miners and their families received over $47.168 billion in federal benefits under this program.

Tracking of silicosis is not as regular or thorough, compared with CWP. However, historic data from the 1990s attributes more than 23% of reported silicosis deaths to mining. On chest x-rays, r-type opacities are associated with silicosis lung pathology. Over the last four decades, researchers have observed an increase in r-type opacities. This increase is primarily for miners in the Central Appalachian region. This change in disease profile for miners diagnosed with pneumoconiosis suggests that U.S. coal miners experience higher crystalline silica exposure than before.

The Diesel Exhaust in Miners Study encompassed more than 12,000 miners. Results showed a significant increased risk of dying from lung cancer among miners who had ever worked underground. This risk increased as the miners’ exposure to respirable elemental carbon – representing diesel exhaust – increased.

How is the NIOSH Mining program addressing this problem?

Reducing miners’ exposure to respirable airborne contaminants directly reduces the risk of developing lung disease. In response, NIOSH Mining:

- identifies sources of high respirable dust and diesel exposure

- evaluates engineering controls that can reduce emissions from these sources

- researches controls and operating practices that can prevent airborne contaminants from reaching workers' breathing zones

- develops sampling instruments that can provide exposure information during or immediately after a working shift

What are the significant findings?

NIOSH Mining has published resources for the mining industry to assist their efforts to control dust and diesel exposure. These include:

- Best Practices for Dust Control in Coal Mining

- Best Practices for Dust Control in Metal/Nonmetal Mining

- Dust Control Handbook for Industrial Minerals Mining and Processing, Second Edition

- Diesel Aerosols and Gases in Underground Mines: Guide to Exposure Assessment and Control

NIOSH research developed a personal dust monitor for miners to wear. This monitor provides an accurate measurement of the miner’s average respirable dust exposure immediately after their shift. The instrument also provides in-shift information on the miner’s ongoing dust exposure. This information can help miners and mine operators identify a potential overexposure. Changes to dust controls or operating practices can then occur to prevent an overexposure. NIOSH and MSHA approved this instrument for use as a continuous personal dust monitor (CPDM). Per the 2014 MSHA dust rule, underground coal mine operators must use a CPDM to demonstrate compliance with the applicable dust limit.

Traditionally, determining silica content requires sending a gravimetric filter to a laboratory for analysis. It can be days or weeks before mine operators receive the results. NIOSH Mining researchers created a technique to measure respirable silica levels onsite immediately after sampling. They take a gravimetric sample, preferably with a specially designed filter cassette. After sampling, the tester places the filter in a portable FTIR instrument. The FTIR instrument then analyzes the sample. PMRD-developed software (FAST) interprets the instrument's output and provides the silica content within a few minutes. Currently, this mine-site technique is most accurate for samples collected in coal mines.

NIOSH developed a video exposure monitoring method to identify sources of dust exposure for mobile miners. These miners have jobs that require them to move throughout the mining operation. In doing so, they can be exposed to multiple dust sources. An instantaneous dust monitor and video camera are worn by the miner while performing their normal work tasks. NIOSH Mining also developed software, Enhanced Video Analysis of Dust Exposure (EVADE), to analyze and display exposure readings. EVADE combines the real-time dust exposure data with the point-of-view video to identify exposure sources for the mobile miner.

NIOSH researchers identified key operating parameters that impact the protection from airborne dust provided by enclosed operator cabs. These parameters informed the development of a model that estimates the protection provided by an enclosed cab. The model can evaluate how the performance of an enclosed cab improves by making changes in these operating parameters.

What are the next steps?

Ongoing research efforts to control airborne contaminants or develop sampling instruments include the following:

- investigating methods to optimize and maintain the performance of flooded bed scrubbers

- evaluating water spray and foam application for reducing coal and silica exposures on longwalls

- investigating the use of water-powered dust scrubbers on longwall shearers

- optimizing "smart" filtration and pressurization systems for enclosed work spaces

- investigating methods to lower exposure to welding fumes

- improving the field-based analysis technique for crystalline silica

- evaluating technologies to prevent diesel overexposures for high-risk jobs in M/NM mines

- evaluating advanced engine technologies for heavy- and light-duty underground vehicles

- evaluating advanced disposable filter elements for use in permissible diesel equipment

- evaluating enclosed cabs and canopy air curtains for controlling diesel aerosols

- examining past and current mining practices to identify potential factors related to high CWP levels

You can find additional information on current research efforts for controlling and monitoring airborne contaminants through the links in the Fast Find box at the top of the page.

For Spanish speakers, view this page with text in Spanish.

- Advanced Strategies for Controlling Exposures to Diesel Aerosols

- Advancing Exposure Monitoring for Airborne Particulates in Mining

- Best Practices for Dust Control in Coal Mining

- Best Practices for Dust Control in Metal/Nonmetal Mining

- Design, Testing, and Modeling of Environmental Enclosures for Controlling Worker Exposure to Airborne Contaminants

- Developing and Improving Respirable Dust Controls in Coal Mines

- Diesel Aerosols and Gases in Underground Mines: Guide to Exposure Assessment and Control

- Dust Control Handbook for Industrial Minerals Mining and Processing. Second edition.

- Emerging Respirable Dust Sensing and Control for M/NM Mining

- EVADE Software - 2.4.6

- Experimental Study on Foam Coverage on Simulated Longwall Roof

- Faces of Black Lung

- FAST - Field Analysis of Silica Tool - 1.0.8

- The Future of Respirable Silica Monitoring: Accurate Results Generated On-site in a Few Minutes

- Improving Protection Against Respirable Dust at an Underground Crusher Booth

- Investigating Mining Practices and Respirable Crystalline Silica Exposures in Underground Coal Mines

- Laboratory and Field Performance of a Continuously Measuring Personal Respirable Dust Monitor

- A New Leak Test Method for Enclosed Cab Filtration Systems

- Testing a Revised Inlet for the Personal Dust Monitor