Mining Project: Advancing Exposure Monitoring for Airborne Particulates in Mining

| Principal Investigator |

|

|---|---|

| Start Date | 10/1/2017 |

| End Date | 9/30/2022 |

| Objective |

To design, validate, and promote the use of advancements in monitoring the exposure of miners to respirable dust, respirable crystalline silica, and diesel particulate matter. |

| Topic Area |

Research Summary

Overexposure to respirable crystalline silica (RCS) can lead to the development of silicosis, which is a disabling, irreversible, and potentially fatal lung disease. The U.S. Mine Safety and Health Administration (MSHA) has an RCS permissible exposure limit (PEL) of 100 µg/m3, and the NIOSH recommended exposure limit (REL) is 50 µg/m3. Based on MSHA data, the percentage of samples from 2013 to 2015 that exceeded the PEL were 10%, 6%, and 5% for samples collected in metal, sand and gravel, and coal mines, respectively. In the same commodities, the percentage of samples that exceeded the REL were 23%, 19%, and 15%. Around 3,000 samples are collected by MSHA every year both in metal/nonmetal mines and in coal mines. In addition, the silica content in respirable dust has been found to be extremely variable in almost every mining commodity.

One of the most significant hurdles in controlling exposure to crystalline silica in the mine environment is the inability to rapidly assess exposure. Using current analysis techniques, it may be weeks before results are obtained. This time lag makes it nearly impossible for the miner to associate specific work practices or mining conditions to high exposures, preventing the application of mitigation techniques or administrative controls before overexposures occur.

To address this problem, one focus of this project was to optimize and facilitate the implementation of a novel, field-based respirable crystalline silica monitoring approach for assessing end-of-shift exposure to empower health and safety staff and miners to avoid or mitigate high crystalline silica levels in the mine environment. This method has been preliminarily developed in a previous Mining Program project, Monitoring and Control of Airborne Toxic Substances in Mining. In the current project, the implementation of the new monitoring approach was improved and tested in a new effort to use advanced monitoring techniques to identify and develop effective control technologies and workplace practices.

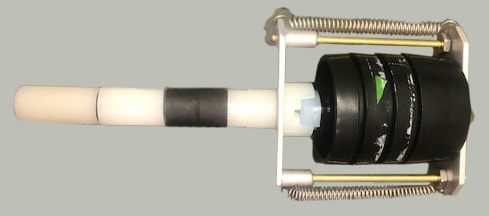

New dust sampling cassette (after use) developed by a manufacturer in collaboration with NIOSH. This cassette facilitates the analysis of dust on the filter and is optimized for the field-based silica monitoring approach. Photo by NIOSH.

One outcome of this project was the adoption of the field-based silica monitoring approach by health and safety professionals in the mining industry in both coal and metal/nonmetal. The adoption, even if in a limited capacity, occurred in both industries. That adoption was facilitated by a new software developed by NIOSH called Field Analysis of Silica Tool (FAST). The FAST software includes algorithms optimized for the silica analysis of samples collected in coal mines. The approach and software can also be used in other mining environments, creating ore-specific quantification models. The project team has continued to work on the development of the analytical monitoring approach which will ultimately be submitted for consideration as a new NIOSH analytical method in the frame of the project, Analytical Enhancement of Rapid Quartz Analysis. The project team has also collaborated with a manufacturer on the creation of a new dust sampling cassette, specifically designed for the field-based silica monitoring approach and now commercially available.

As a second outcome, this project performed two case studies at aggregate operations in which the field-based silica monitoring approach was being merged in conjunction with the Helmet-CAM assessment technology. The goal was to demonstrate the benefit of these advanced monitoring approaches for the identification and control of respirable dust and silica at mine sites and for increasing the awareness and engagement of companies, corporate health and safety offices, and workers.

NIOSH researchers collecting area respirable dust samples at a sandstone mine to demonstrate the efficacy of advanced monitoring approaches such as field-based silica monitoring and Helmet-CAM. Photo by NIOSH.

Finally, this project investigated new and modified coal mine dust sampling and monitoring devices. This investigation was part of NIOSH’s statutory obligation to approve new and modified coal mine dust sampling devices under 30 CFR 74.

News

The Field Analysis of Silica Tool (FAST) software is now available as a beta version on the NIOSH Mining website. A press release announcing the software was published on the Occupational Health & Safety website on October 4, 2018.

Recent Related Publications

NIOSH [2022]. Direct-on-filter analysis for respirable crystalline silica using a portable FTIR instrument. By Chubb LG, Cauda EG. Pittsburgh PA: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2022–108, IC 9533. https://www.cdc.gov/niosh/mining/works/coversheet2175.html

Cauda E, Dolan E, Cecala A, Louk K, Yekich M, Chubb L, Lingenfelter A [2022]. Benefits and limitations of field-based monitoring approaches for respirable dust and crystalline silica applied in a sandstone quarry. J Occup Environ Hyg 19(12):730-741. https://www.tandfonline.com/doi/full/10.1080/15459624.2022.2132257

Wolfe C, Chubb L, Walker R, Yekich M, Cauda E [2022]. Monitoring worker exposure to respirable crystalline silica: Application for data-driven predictive modeling for end-of-shift exposure assessment. Ann Work Expo Health 66(8): 1010-1021. https://doi.org/10.1093/annweh/wxac040

Chubb, LG, Cauda EG [2021]. A novel sampling cassette for field-based analysis of respirable crystalline silica. J Occ Env Hyg 18(3):103-109. https://www.tandfonline.com/doi/full/10.1080/15459624.2020.1868481

Walker LT, Cauda E, Chubb L, Krebs P, Stach R, Mizaikoff B, Johnston C [2021]. Complexity of respirable dust found in mining operations as characterized by X-ray diffraction and FTIR analysis. Minerals 11(4):383-406. https://www.mdpi.com/2075-163X/11/4/383

Ashley EL, Cauda E, Chubb LG, Tuchman DP, Rubinstein EN [2020]. Performance comparison of four portable FTIR instruments for direct-on-filter measurement of respirable crystalline silica. Ann Work Exp Health 64(5):536-546. https://academic.oup.com/annweh/article/64/5/536/5817577

Pampena J, E Cauda, L Chubb, and J Meadows (2020). Use of the field-based silica monitoring technique in a coal mine: a case study. Min Met Expl 37:717-726. https://link.springer.com/article/10.1007/s42461-019-00161-0

Presentation at the NIOSH-MSHA Workshop: Silica Exposure and Lung Disease in the Mining Industry. Field-based monitoring techniques for respirable dust and crystalline silica: A case study in a sandstone quarry. https://www.cdc.gov/niosh/mining/content/SilicaExposureMiningWorkshop.html#Recordings

Project Team

Emanuele Cauda—General Engineer

Lauren Chubb—Physical Scientist

Jon Hummer—Engineering Technician

Donald Tuchman—Industrial Hygienist

Dylan Ritter—Engineering Technician

Shawn Vanderslice—Engineering Technician

Rachel Walker—Associate Fellow

Cody Wolfe—Associate Fellow

Milan Yekich—Engineering Technician

- Analysis of the Silica Percent in Airborne Respirable Mine Dust Samples from U.S. Operations

- Closing the Door to Dust When Adding Drill Steels: Uni-directional Cab Filtration and Pressurization System Tested

- Control of Respirable Dust

- Criteria for a Recommended Standard: Occupational Exposure to Respirable Coal Mine Dust: Occupational Exposure to Respirable Coal Mine Dust

- The Effects of Low Quartz Mass Loading and Spatial Variability on the Quartz Analysis of Surface Coal Mine Dust Samples

- The Future of Respirable Silica Monitoring: Accurate Results Generated On-site in a Few Minutes

- Improving Silica Dust Control Through Targeted Research

- Improving the Performance of Fan-Powered Dust Collectors in Stone-Cutting Applications

- Laboratory Evaluation of a Canopy Air Curtain for Controlling Occupational Exposures of Roof Bolters

- Reducing Enclosed Cab Drill Operator's Respirable Dust Exposure at Surface Coal Operation With a Retrofitted Filtration and Pressurization System