Key points

- No single control measure ensures the control of Legionella in potable water systems.

- Potable water is a term used for hot or cold water intended for people to drink.

- Thermal remediation isn't recommended for potable water systems.

Purpose

Use this document to:

- Help evaluate hazardous conditions associated with potable water systems

- Implement Legionella control measures for potable water systems per ASHRAE Guideline 12

- Complement existing resources for water management programs (WMPs)

- Support environmental assessments conducted during public health investigations

Design

Understanding potable water system design components is critical for Legionella control. The following considerations apply to hot and cold potable water systems. Evaluate them from the point water enters a facility system to where it leaves the system through a fixture or device.

Design recommendations

Use pipe insulation to maintain hot- and cold-water temperatures throughout the water system.

Eliminate dead legs, which are sections of no- or low-water flow.

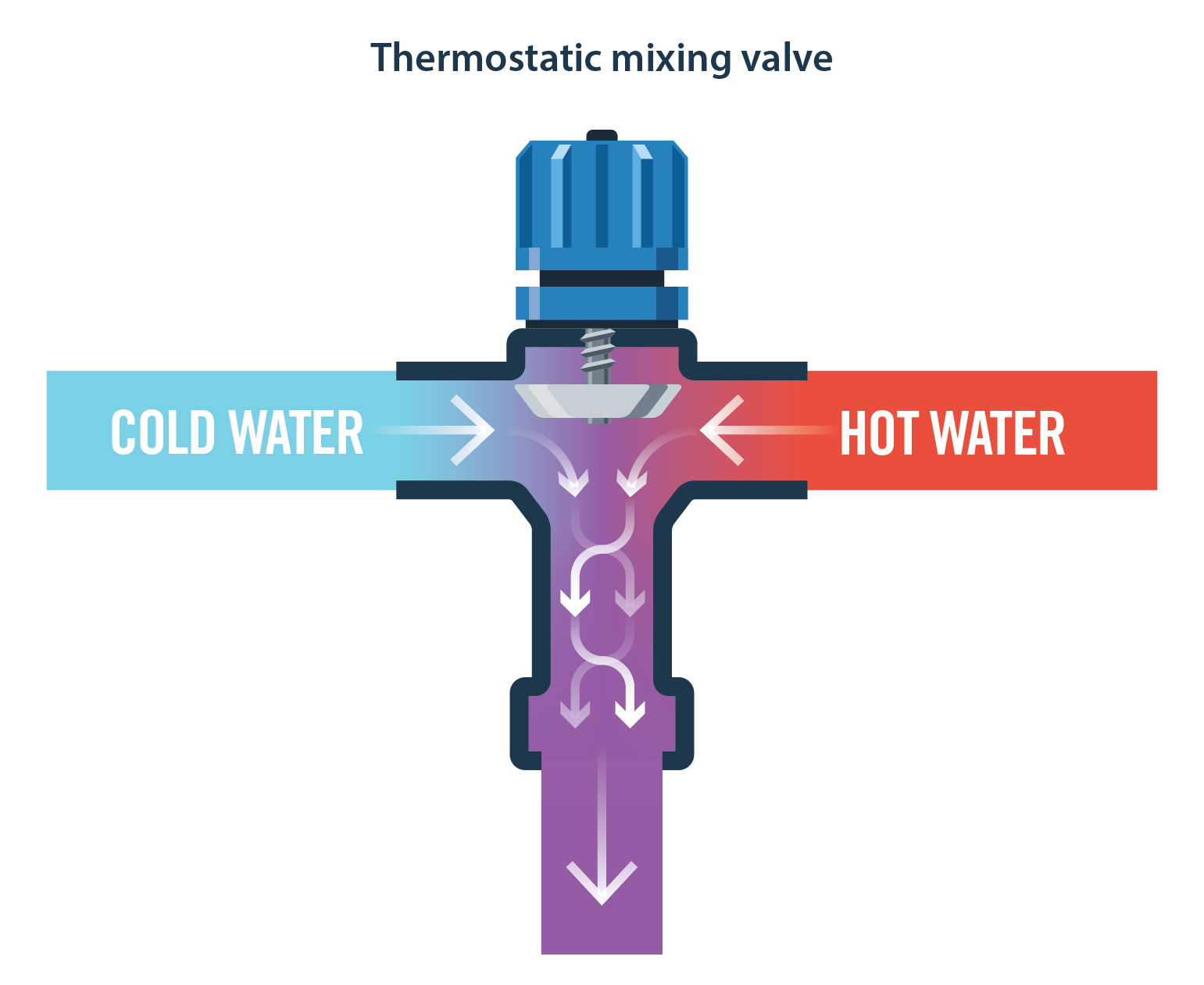

Install thermostatic mixing valves as close as possible to fixtures. This will prevent scalding while permitting circulating hot water temperatures above 120°F (49°C).

Recognize Legionella risks of low-flow and mechanically complex fixtures (e.g., electronic sensor faucets).

Consider impact on disinfectant residuals: Identify water system components that speed the decay of disinfectant residuals. This can include UV devices, water softeners, carbon filters, and heaters.

Water storage tanks: Select appropriately sized hot- and cold-water storage tanks. Fit them with recirculating pumps to maintain flow and avoid unfavorable temperature gradients.

Consider installing sampling ports throughout your water system in locations to facilitate water parameter monitoring and WMP validation.

Water management program

No single measure can ensure Legionella control.

WMP recommendations

Use a comprehensive WMP to layer a series of complementary control measures to protect occupants and visitors from exposure to Legionella. Together these control measures can create environmental conditions that prevent bacterial intrusion, growth, and transmission.

Operation, maintenance, and control limits

Guidance

Monitor temperature, disinfectant residuals, and pH frequently based on performance of WMP or Legionella performance indicators for control. Adjust measurement frequency according to the stability of performance indicator values. For example, increase the measurement frequency if there's a high degree of measurement variability.

Hot water: Store hot water at temperatures above 140°F (60°C). Ensure hot water in circulation does not fall below 120°F (49°C). Recirculate hot water continuously, if possible.

Cold water: Store and circulate cold water at temperatures below the favorable range for Legionella (77–113°F, 25–45°C). Legionella may grow at temperatures as low as 68°F (20°C).

Flushing: Flush low-flow piping runs and dead legs at least weekly. Flush infrequently used fixtures (e.g., eye wash stations, emergency showers) regularly as needed to maintain water quality parameters within control limits.

Ensure disinfectant residual is detectable throughout the potable water system.

Clean and maintain water system components, such as thermostatic mixing valves, aerators, showerheads, hoses, filters, and storage tanks, regularly.

Consider testing for Legionella in accordance with the routine testing module of this toolkit (linked below).

Additional guidance

Supplemental disinfection systems

Don't presume supplemental disinfection systems will control Legionella without an adequate WMP. Selecting or operating a supplemental disinfection system inappropriately may result in system damage or health hazards (e.g., disinfectant byproducts). Consult with a water treatment professional regarding supplemental disinfection systems. They may require permitting.

Point-of-use filters

When integrated into a WMP, point-of-use (POU) microbial filters can provide immediate control if they:

- Have an effective pore size of 0.2-microns or less

- Comply with the requirements of ASTM F838

However, POU filters protect only the connected fixture not the entire water system. Selecting the correct location is critical to Legionella exposure prevention across the water system.

Follow the manufacturer recommendations regarding frequency of replacement and appropriate operating conditions.

POU filters may need to be removed before performing an acute remediation procedure.

Remediation

Role of testing during remediation

If an outbreak or illness is suspected, test in conjunction with public health in order to:

- Confirm the presence of Legionella before performing remediation.

- Confirm elimination of Legionella after remediation activities.

Indications for remediation

Consider the remediation options described below if

- Control measures are ineffective

- Routine results indicate poor Legionella control

- The authority having jurisdiction suspects an outbreak or illness

Note: The public health authority having jurisdiction determines whether there's associated illness(es) or an outbreak.

Remediation options

Choose a remedial treatment procedure after considering the system infrastructure, water quality parameters, and available sampling results. Consult with a water treatment professional as certain procedures should only be undertaken by a professional.

Chemical shock using an elevated level of a disinfectant for a limited duration can control Legionella in a potable water system. Consult scientific evidence and technical expertise before choosing a specific chemical shock procedure.

- Consider which components of the water system need remediation.

- Lowering the hot water system's temperature may improve the procedure's efficacy.

- Regulations may impact chemical shock options.

- Example: Chemicals allowed into sewer discharge

- Some chemical shock options may require permitting.

Thermal shock isn't recommended

Thermal shock of water systems isn't recommended due to frequent failure and rapid recolonization of Legionella.

Legionella control measures

Described below are control measures and recommendations for each water parameter.

Sediment and biofilm

Control measures: Flushing, cleaning, and maintenance

Recommendations: Flush after an intrusion event (e.g., water main break).

Clean and maintain water system components regularly as indicated by water quality measurements. Components include water heaters, mixing valves, aerators, showerheads, hoses, and filters.

Temperature

Control measures: Control limits

Recommendations: Store hot water above 140°F (60°C). Maintain circulating hot water above 120°F (49°C).

Store and maintain circulating cold water below the growth range most favorable to Legionella (77–113°F, 25–45°C). Note that Legionella may grow at temperatures as low as 68°F (20°C).

Water age

Control measures: Flushing

Recommendations: Flush low-flow pipe runs and dead legs at least weekly.

Flush infrequently used fixtures regularly.

Disinfectant residual

Control measures: Control limitsA

Recommendations:

- Chlorine: Detectable residual as directed by WMP.

- Monochloramine: Detectable residual as directed by WMP.

- Disinfectant residual recommendations apply to disinfectant delivered by the municipal water authority. Supplemental disinfection system control limits aren't prescribed here and must be dictated by the water treatment professional and water management program.