Flavoring Exposure Control and Intervention

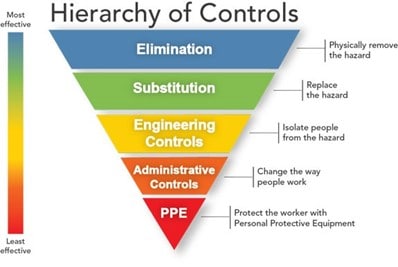

Image by NIOSH

If air levels of diacetyl or 2,3-pentanedione in the workplace exceed occupational exposure limits, workplace controls and interventions should be put in place to reduce health risks. Repeated air sampling can help evaluate whether the interventions are working as designed.

NIOSH recommends employers take steps to reduce occupational exposures to diacetyl and 2,3-pentanedione to below the recommended exposure limits (RELs). The objective in establishing RELs for diacetyl and 2,3-pentanedione is to reduce the risk of respiratory impairment and obliterative bronchiolitis, a severe irreversible lung disease associated with occupational exposure to these chemicals. Go to Occupational Exposure Limits for detailed information.

The hierarchy of controls is an approach that groups actions by their likely effectiveness in removing or reducing hazards. Examples of workplace controls and interventions based on the hierarchy of controls include the following:

- Eliminate exposures by completely removing task locations that do not involve diacetyl or 2,3-pentanedione (or other potentially harmful chemicals).

- Substitute by using less hazardous chemicals. This step should be completed after carefully evaluating potential substitutes for toxicity.

- Use engineering controls such as closed systems, isolation, or local exhaust ventilation.

- Establish administrative controls for work practices to minimize exposure.

- Train and inform employees on potential hazards in the workplace and associated safe practices, procedures, and protective measures to protect themselves.

- Use personal protective equipment, where needed, in addition to engineering or administrative controls to limit exposure to workplace hazards. Proper respiratory protection requires a comprehensive respiratory protection program and a high level of employee and management involvement and commitment. This is to assure:

- Respirators are worn when they are needed.

- Respirators do not present a health hazard to the worker.

- Workers are trained to use respirators properly.

- The right type of respirator is chosen for each hazard.

- Well-fitting respirators are worn and maintained in proper condition.

It is also important to monitor occupational exposures and the status of workers’ health. This includes tracking potential symptoms or cases and reporting symptoms or cases to NIOSH and state health departments.

Workers exposed to flavoring chemicals in flavoring manufacturing plants, and workers exposed to butter flavoring chemicals in the production of different food products, should have their lung function checked by their healthcare provider on a regular basis to help detect abnormalities that may be work-related.

NIOSH has developed guidance in a variety of areas to reduce workers’ exposures to diacetyl and 2,3-pentanedione through engineering controls, best work practices, and techniques for monitoring airborne diacetyl exposures. To view the guidelines, visit Best Practices: Engineering Controls, Work Practices, and Exposure Monitoring for Occupational Exposures to Diacetyl and 2,3-Pentanedione. The Occupational Safety and Health Administration (OSHA) also provides information related to flavorings on their Flavorings-Related Lung Disease website.

References

1Hirst DV, Dunn KH, Shulman SA, Hammond DR, Sestito N [2014]. Evaluation of engineering controls for the mixing of flavorings containing diacetyl and other volatile ingredients. J Occup Environ Hyg 11(10):680-687.

2Kanwal R, Kullman G, Fedan KB, Kreiss K [2011]. Occupational lung disease risk and exposure to butter-flavoring chemicals after implementation of controls at a microwave popcorn plant. Public Health Rep. 126(4):480-494.