15-Year-Old Part-Time Worker at Retail Grocery Store Suffers Amputation While Assembling Meat Grinder – Utah

NIOSH In-house FACE Report 2000-13

Summary

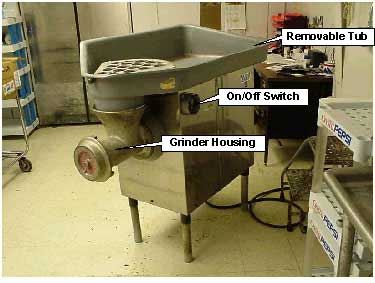

On February 14, 2000, a 15-year-old part-time worker (the victim) at a retail grocery store suffered amputation of the right arm as a result of being caught by the auger of a meat grinder while he was reassembling it. The victim, working after school, had completed washing and cleaning the disassembled parts of the grinder and was reassembling it without de-energizing and locking out the machine’s power supply (Photo 1). He inserted the auger into the grinder’s housing and reached through the feed-throat with his right hand to guide it into engagement. As he did so, he bumped against the on/off switch mounted about waist high on the machine’s side. The grinder started and the auger pulled his hand and arm into the housing. He turned the machine off, pulled his arm from the grinder housing and ran toward the front of the store. The store manager applied pressure to his bleeding arm while a coworker called 911. The victim was transported to a local hospital. His right arm had been amputated just below the elbow.

NIOSH investigators concluded that, to help prevent similar occurrences, employers should:

- develop and implement appropriate procedures to control the release of hazardous energy, including lockout/tagout procedures

- ensure that all equipment, including manufacturer-provided safety devices, is maintained in safe operating condition

- ensure that all equipment is surveyed regularly to identify appropriate safety control improvements

- know and comply with child labor laws that establish the types of work that 14- and 15-year olds may perform

- ensure that workers are trained to recognize and avoid the hazards of equipment operation and maintenance.

Introduction

On February 14, 2000, a 15-year-old cleanup and stocking laborer (the victim) at a retail grocery store suffered amputation of his right arm after he was caught by the auger of the meat grinder he was reassembling. On March 15, 2000, the U.S. Department of Labor, Wage and Hour Division notified NIOSH’s Division of Safety Research (DSR) of the occurrence. On April 19, 2000, a DSR safety engineer traveled to the incident site, examined and photographed the meat grinder, and interviewed the grocery store owner and operations manager. On April 20, 2000, the safety engineer met with the Wage and Hour investigator, reviewed the case file, and discussed the case.

The employer was an independently owned retail grocery store employing 50 workers, 17 of whom were under the age of 18. The store had implemented a written procedures policy and employee’s handbook. This policy addressed issues of cleanliness, housekeeping, attendance, customer satisfaction, and employee behavior. Safety procedures addressed elimination of slip, trip, and fall hazards from clutter, spilled products, and water. Department managers provided each employee with on-the-job training in department-specific safe work procedures. The written policy did not address age-appropriate tasks or control of hazardous energy.

The victim had been hired to work part-time after school and on weekends. He had been working after school about 2 hours a day for under 1 month. He had worked one Saturday during a sale. His regular job task was to clean the meat department and wash down the tables and tools. Because he was under the age of 18, he had been instructed not to operate or touch any of the powered meat processing machines except for the grinder. His only task related to the grinder was to wash and clean the parts after the grinder had been disassembled by older workers at the end of each work day. After cleaning the grinder parts the victim was to reassemble them. This was the company’s first serious injury.

Back to Top

Investigation

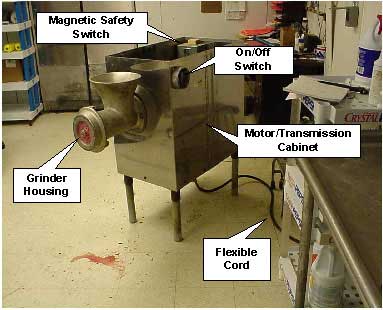

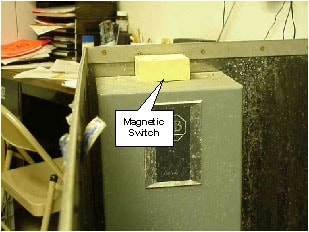

The machine involved in this incident was a meat grinder powered by a 5-horsepower electric motor. Electric power was supplied by a flexible cord and plug connected to a wall receptacle. The receptacle, located behind a desk in the meat department, was inaccessible for routine disconnection and the flexible cord remained connected at all times. The machine was equipped with a chain-driven auger that rotated inside a barrel-shaped housing. Meat was fed into the grinder through a hopper-shaped feed-throat and extruded through grinder plates by the auger (Photo 2). The grinder was controlled by an on/off switch operated by a lever mounted on the left side of the motor/transmission cabinet. Prior to the incident, this switch had been unprotected from inadvertent operation. The motor/transmission cabinet was covered with a removable plastic tub which held the material being fed into the grinder throat. The machine was equipped with a magnetic safety switch mounted on top of the motor starter such that a magnet mounted underneath the plastic tub would activate it, allowing the motor to operate (Photo 3). When the tub was removed from the grinder, the switch would interrupt electric power to the motor, preventing operation. This switch, however, had not been functional since before the store was purchased 16 years earlier. Store employees were not aware of the presence of this switch until after the incident.

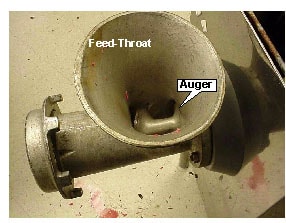

On the day of the incident, the victim started work between 5:30 p.m. and 6:00 p.m. He followed his normal routine by cleaning the metal tables and the grinder tub. The grinder had been shut down and disassembled prior to his arrival at work. The flexible cord for the grinder, however, remained connected to the energized receptacle behind the desk, and the plastic tub remained off the motor/transmission cabinet. After cleaning the parts, he began to reassemble the meat grinder. He attached the barrel-shaped grinder housing, finger-tightening the four bolts that secured it to the transmission case. He then inserted the grinder’s auger through the front of the housing. He reached through the feed hopper and into the housing with his right hand to guide the auger into engagement with the drive mechanism (Photo 4). Evidence suggests that as he did so, he inadvertently leaned against the on/off switch lever and moved it to the on position. The grinder started and the auger began to feed his hand and arm through the grinder housing. He shut down the machine and withdrew his arm. He then left the meat department room and made his way to the front of the store. He was assisted by the store manager who applied pressure to the injured right arm to control bleeding. One of the store cashiers called 911. EMS responded within 10 minutes to the site and the victim was transported to a local hospital.

Back to Top

Injury

As a result of the incident, the victim suffered amputation of the lower right arm.

Recommendations and Discussion

Recommendation #1: Employers should develop and implement appropriate procedures to control the release of hazardous energy, including lockout/tagout procedures.

Discussion: Power to the grinder was supplied by a flexible cord and plug connected to a wall receptacle. This receptacle was located behind a desk in the meat department. Because this location rendered the receptacle and plug inaccessible for easy disconnection, and because no one at the store recognized the hazard of working on the energized meat grinder, the flexible cord remained connected at all times. This left the on/off switch as the only protection against uncontrolled release of hazardous energy while working on, disassembling, cleaning, and reassembling the grinder.

After the incident, the employer implemented a hazardous energy control policy that required relocating the switch to a readily accessible wall location near the grinder’s work location and procedures to lock out and tag the flexible cord plug at the end of each working day or when servicing or repairing the equipment. Additionally, the grinder’s on/off switch lever was protected from inadvertent activation by an open-faced enclosure.

Recommendation #2: Employers should ensure that all equipment, including manufacturer-provided safety devices, is maintained in safe operating condition.

Discussion: After the incident, the employer obtained the services of a food service machinery technical representative to conduct an examination of the grinder. As a result of the examination, it was learned that the grinder had been equipped with a magnetic safety switch that would interrupt the power when the plastic tub was removed. At the time the employer had purchased the store and grinder, the switch was not functioning, and the employer and meat department staff had been unaware that the machine had ever been equipped with such a device. The switch was mounted on top of the motor starter enclosure (Photo 3). It was designed to be pulled closed by a magnet mounted underneath the plastic grinder tub, located directly over the switch when the tub was in place. Apparently the magnet had loosened and fallen from the tub, and the switch had been bypassed electrically by a previous store owner. Had this switch been operable, the machine would not have started when the on/off switch was inadvertently activated with the tub removed. To ensure that all safety devices are operable, employers should contact manufacturers or equipment distributors to examine equipment when purchased, especially if previously owned, and restore it to safe condition. Additionally, the equipment should be examined regularly by employees who have been trained to recognize the hazards of operating the machine and in the correct operation of safety devices. All defects identified should be corrected before returning the equipment to service.

Recommendation #3: Employers should ensure that all equipment is surveyed regularly to identify appropriate safety control improvements.

Discussion: After the incident the employer guarded the on/off switch by mounting it inside an open-faced enclosure, fabricated from a commonly available electrical junction box (Photo 5). This guarding method provides protection against inadvertent switch activation equivalent to a recessed switch design. It should be noted that the manufacturer of the grinder in the incident provides similar protection for currently produced machines by mounting a u-shaped guard fabricated from metal rod over the on/off switch (see Figure). Employer-conducted surveys of equipment performed with the assistance of equipment distributors’ representatives could facilitate the identification of appropriate updated safety controls for machine applications. Although not a substitute for the implementation of a proper hazardous energy control policy requiring de-energizing, locking and tagging energy sources before conducting machine maintenance, the application of a switch guard may have prevented this incident.

Recommendation #4: Employers should know and comply with child labor laws that establish the types of work that 14- and 15-year olds may perform.

Discussion: The Fair Labor Standards Act (FLSA) includes provisions to protect youth by prohibiting their employment under conditions that would be detrimental to their health or well-being. These provisions address appropriate occupations for specific age groups. Youths 14 and 15 years old are prohibited from occupations

- requiring the performance of duties in work rooms or work places where goods are manufactured, mined, or processed [29 CFR Part 570.33(a)]

- involving the tending, including the cleaning and assembling of power-driven machinery [29 CFR Part 570.33(b)]

- involving operating, setting up, cleaning, oiling, or repairing power-driven food grinders [29 CFR 570.34 (b)(6)]

Additionally, because operating power-driven meat grinders has been found to be particularly hazardous, a minimum age of 18 has been established for workers who operate these machines. These employment standards are listed and explained in bulletin WH-1330, U.S. Department of Labor, Employment Standards Administration, Wage and Hour Division.1 According to the employer, the victim had been hired to clean up the meat department and wash disassembled equipment. He had been specifically instructed not to touch the other machines such as meat saws and cutting machines in the meat department and to reassemble the meat grinder with “finger-tight” connections only.

Recommendation #5: Employers should ensure that workers are trained to recognize and avoid the hazards of equipment operation and maintenance.

Discussion: According to the employer, the victim had been verbally instructed not to touch the power-driven meat processing equipment used in the meat department. His job task related to the meat grinder was limited to cleaning disassembled parts and partial reassembly. It is unclear to what extent the grinder was to be reassembled. According to the employer, the victim had been instructed to only install the barrel-shaped auger housing, tightening the mounting bolts and nuts finger-tight. The victim, however, believed his reassembly task was more extensive. Instructing unauthorized workers that they are restricted from operating and maintaining certain types of equipment may control exposure to equipment hazards. However, the instruction should include identification of the hazard such restrictions are intended to protect against, especially when these task restrictions apply only partially to a simple machine such as the grinder in this incident. Excluding the grinder’s drive motor, switch box, and transmission which would not be disassembled for routine cleaning, there were only four components to clean and reassemble: a barrel-shaped housing, an auger, a grinder plate, and a lock ring to secure the auger and grinder plate in the housing. The assembly procedure was simple and could easily be deduced without instruction. However, the consequences of inadvertently activating the on/off switch while assembling the parts to the grinder’s energized motor and drive mechanism may not have been so obvious.

Reference

DOL [1991]. Child Labor Requirements in Nonagricultural Occupations Under the Fair Labor Standards Act, U. S. Department of Labor, Employment Standards Administration, Wage and Hour Division, WH-1330, revised September 1991.

Investigator Information

This investigation was conducted by Paul H. Moore, Safety Engineer, Fatality Assessment and Control Evaluation Team, Surveillance and Field Investigations Branch, Division of Safety Research.

Back to Top

Photographs

|

|

|

|

|

|

Photo 5. On/Off Switch Protected by Open-Faced Enclosure

|

|

|

Figure. Switch Protected by U-Shaped Guard

|

The FACE investigation project is the cornerstone of the overall NIOSH program to prevent occupational fatalities. The objectives for this effort include the investigation of occupational fatalities to assess and characterize the circumstances of these events in order to develop succinct descriptive and evaluative reports for distribution to occupational safety and health groups across the country. This work is being conducted by the FACE investigation team. It is expected that the reports alone will have a major impact by better defining the causal factors behind occupational fatalities, calling national attention to the problem, and providing insights into the prevention efforts that are needed. However, the program does not determine fault or place blame on companies or individual workers.