Preventing Silicosis and Deaths in Rock Drillers

August 1992

DHHS (NIOSH) Publication Number 92-107

WARNING! Exposure to crystalline silica during rock drilling can cause serious or fatal respiratory disease.

The National Institute for Occupational Safety and Health (NIOSH) requests assistance in preventing silicosis and deaths in workers exposed to respirable crystalline silica. The need is urgent to inform surface coal mine and other rock drillers, driller helpers, employers of drillers, and drill rig manufacturers about the respiratory hazards associated with drilling operations. Your assistance in this effort will help prevent silicosis-related death and disease, a national goal for health promotion and disease prevention stated in Healthy People 2000 [DHHS 1990].

This Alert describes 23 cases of silicosis from exposure to crystalline silica during rock drilling. Of the 23 workers reported, 2 workers have already died from the disease, and the remaining 21 may die eventually from silicosis or its complications.

NIOSH requests that editors of trade journals, safety and health officials, labor unions, and employers bring the recommendations in this Alert to the attention of all workers who are at risk. NIOSH also requests that manufacturers of drill rigs and other rock drilling equipment become familiar with and implement the source control measures recommended in this Alert.

Background

Silicosis has been recognized in rock drillers employed in caisson construction [Ng et al. 1987], metal mining [Ezenwa 1982], slate quarries [Sacharov et al. 1971], tunnel construction [Burns et al. 1962; Bavley 1950; Cherniack 1989], highway and dam construction [Burns et al. 1962], and rock quarries [Ahlman et al. 1975]; Guénel et al. 1989]. Although rock drillers in underground coal mines (roof bolters, for example) have developed silicosis [Tomb et al. 1986], those in surface coal mines have not historically been considered at significant risk [Fairman et al. 1977]. However, recent studies suggest that surface coal mine drilling presents a serious respiratory hazard to drillers and driller helpers. Furthermore, most of the recent case reports on silicosis in rock drillers involve surface coal mine drillers [Banks et al. 1983; Parker et al. 1989; Goodman et al. 1992; Maksimovic and Page 1986; Amandus et al. 1984, 1989; Piacitelli et al. 1990; Amandus and Piacitelli 1987].

Surface Mining Process

An early step in the surface or strip mining process is the removal of topsoil and other overburden materials, including sandstones, shales, limestones, and unconsolidated soils. Removal of these materials may require drilling holes into the rock formation to accept explosive charges for blasting. After blasting, the debris is cleared with earth-moving equipment such as drag line cranes, end loaders, or power shovels.

Silica Exposure During Surface Mine Drilling

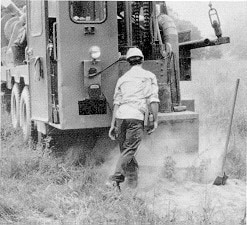

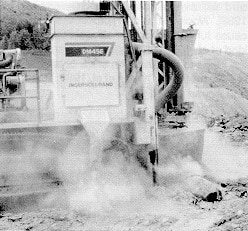

When the drilled rock has significant crystalline silica* content, the drill operators and helpers may be exposed to large amounts of respirable crystalline silica. Such exposure places these workers at high risk of developing silicosis. Rock drillers operate large, mobile rotary rigs that drill holes in the rock (Figure 1). Compressed air is often used to keep the drill hole clear and to cool bit-cutting points and bearings. This process frequently generates large clouds of dust containing crystalline silica (Figure 2).

Operators of earth-moving equipment may also be exposed to silica when removing overburden materials.

Figure 1. Rock driller working without respiratory protection on a mobile rig.

Figure 2. Typical dusty atmosphere created by rock drilling operations.

Current Exposure Limits

Rock drillers working at surface and underground mines are covered by Mine Safety and Health Administration (MSHA) regulations. Nonmining hard rock drillers are covered by Occupational Safety and Health Administration (OSHA) regulations.

MSHA PEL

Surface coal mines

Surface coal mine operators must comply with the MSHA permissible exposure limit (PEL) of 2.0 milligrams of respirable coal mine dust per cubic meter of air (2mg/m3). However, when the respirable quartz (crystalline silica) content of the dust is greater than 5%, the PEL is reduced as follows [30 CFR** 71.101]:

![]()

Metal and nonmetal surface and underground mines

For metal and nonmetal surface and underground mines, the MSHA PEL for respirable dust is calculated as follows [30 CFR 56.500]:

![]()

OSHA PEL

The current OSHA PEL for respirable crystalline silica (quartz) is an 8-hour time-weighted average (TWA) of 100 micrograms per cubic meter (100 µg/m3, or 0.10 mg/m3) [29 CFR 1910.1000].

NIOSH REL

The NIOSH recommended exposure limit (REL) for respirable crystalline silica is 50 µg/m3 as a TWA for up to 10 hours/day during a 40-hour workweek [NIOSH 1974]. This REL is intended to prevent silicosis. However, evidence indicates that crystalline silica is a potential occupational carcinogen [NIOSH 1988; IARC 1987; DHHS 1991], and NIOSH is in the process of reviewing the data on carcinogenicity.

Health Effects of Crystalline Silica Exposure

A worker may develop any of three types of silicosis, depending on the airborne concentration of crystalline silica:

- Chronic silicosis, which usually occurs after 10 or more years of exposure to crystalline silica at relatively low concentrations

- Accelerated silicosis, which results from exposure to high concentrations of crystalline silica and develops 5 to 10 years after the initial exposure

- Acute silicosis, which occurs where exposure concentrations are the highest and can cause symptoms to develop within a few weeks to 4 or 5 years after the initial exposure [Peters 1986; Ziskind et al. 1976]

Silicosis (especially the acute form) is characterized by shortness of breath, fever, and cyanosis (bluish skin); it may often be misdiagnosed as pulmonary edema (fluid in the lungs), pneumonia, or tuberculosis. Severe mycobacterial or fungal infections often complicate silicosis and may be fatal in many cases [Ziskind et al. 1976; Owens et al. 1988; Bailey et al. 1974]. Fungal or mycobacterial infections are believed to result when the lung scavenger cells (macrophages) that fight these diseases are overwhelmed with silica dust and are unable to kill mycobacteria and other organisms [Allison and Hart 1968; Ng and Chan 1991]. About half of the mycobacterial infections are caused by Mycobacterium tuberculosis, with the other half caused by M. kansasii and M. avium-intracellular [Owens et al. 1988]. Nocardia and Cryptococcus may also cause lung infections in silicosis victims [Ziskind et al. 1976]. Investigations usually show the lungs to be filled with silica crystals and a protein material [Owens et al. 1988; Buechner and Ansari 1969].

Case Reports

Case No. 1–Acute Silicosis

A 33-year-old male quarry rock driller developed respiratory symptoms in August 1986 after working in Pennsylvania surface coal mines since 1975 [Goodman et al. 1992]. A chest X-ray in August 1986 showed relatively minor abnormalities, but the worker’s symptoms improved and he continued to work.

In May 1987, the driller’s respiratory symptoms returned along with severe weight loss, fevers, night sweats, joint pain, reduced lung function, swollen lymph nodes, and progressive worsening of his chest X-ray. Antibiotics did not improve his condition, and open lung biopsies confirmed acute silicosis.

After treatment with high-dose corticosteroids and antituberculosis drugs, the driller stabilized and improved slightly until February 1990, when his condition deteriorated. He died of progressive respiratory failure from silicosis in September 1991.

The driller reported that most of the drilling he did before 1983 involved wet techniques to suppress dust. Thereafter he drilled without dust suppression measures and without a respirator, even though the dust was sometimes so thick that he “couldn’t see anything.”

Case No. 2–Acute and Accelerated Silicosis

In April 1979, a 34-year-old male rotary driller reported a 6-month history of shortness of breath, dry cough, weight loss, and pale skin color in body extremities [Banks et al. 1983]. For the preceding 5 years, this worker had operated a rotary drill at a surface coal mine using dry drilling methods. Examination revealed increased heart and breathing rates, abnormal lung sounds, healed ulcers on the fingertips, reduced lung function, and abnormal chest X-rays. Open lung biopsy confirmed acute silicosis. Although the patient was treated with aggressive therapy for 8 months, lung function continued to deteriorate and the patient died of respiratory failure in June 1981.

Discovery of this case of acute silicosis led to a medical survey of nine other drillers who worked for the same company. Two of the workers, aged 28 and 31, had accelerated silicosis and had been drillers for fewer than 6 years. Exposure concentrations are unknown because the crystalline silica content was not measured in the coal dust samples collected during the years 1972-80. However, much of the rock encountered by the drillers was sandstone, which is likely to have had a high crystalline silica content.

Case No. 3–Accelerated and Chronic Silicosis

Seven cases of silicosis in surface miners were reported from a single hospital in West Virginia during the period 1978-88 [Parker et al. 1989]. All cases were in men aged 25 to 51 who were involved with surface drilling for 3 to 19 years.

Five of the drillers suffered from accelerated silicosis: one was infected with Mycobacterium tuberculosis, one had a positive tuberculin skin test without proven active infection, and one had progressive massive fibrosis (a condition in which large areas of lung tissue become scarred and collapse).

The other two drillers suffered from chronic silicosis. Both were in advanced stages of the disease, including progressive massive fibrosis.

Case No. 4–Chronic Silicosis

A survey of 18 caisson drilling sites in Hong Kong [Ng et al. 1987] identified 12 cases of chronic silicosis among 118 workers exposed to high concentrations of silica. Six of these workers also had active cases of tuberculosis. All 12 workers had 10 to 20 years of occupational exposure.

Site visits showed little evidence of attempts to control dust at the source. For example, dust suppression measures were not used with pneumatic tools, and exhaust ventilation was not supplied in the shafts. In deeper caissons, fresh air was usually supplied by a compressor through a makeshift duct, but the blowing increased airborne dust concentrations. Some dust was suppressed by the natural seepage of water at the bottom of the excavation, and workers at some sites routinely wet the workface to suppress dust.

In the past, reusable cloth masks were commonly used at caisson drilling sites. More recently, however, workers have provided their own particulate filter masks.

Conclusions

The cases of silicosis described in this Alert illustrate the risk of serious or fatal illness in rock drillers and the conditions that favor the development of silicosis. These conditions are as follows:

- The presence of respirable crystalline silica dust

- Inadequate dust control measures

- Inadequate respiratory protection

- The absence of adequate medical screening and monitoring programs

- The absence of adequate air monitoring programs for respirable dust

Recommendations

NIOSH recommends the following measures to reduce crystalline silica exposures in the workplace and prevent silicosis and silicosis-related deaths:

- Before mining begins, assess the potential for exposing workers to crystalline silica during removal of the overburden.

- Conduct air monitoring to measure worker exposures.

- Use control measures such as wet drilling and exhaust ventilation to minimize exposures.

- Practice good personal hygiene to avoid unnecessary exposure to silica dust.

- Wear washable or disposable protective clothes at the worksite; shower and change into clean clothes before leaving the worksite to prevent contamination of cars, homes, and other work areas.

- Use respiratory protection when source controls cannot keep silica exposures below the NIOSH REL.

- Provide periodic medical examinations for all workers who may be exposed to crystalline silica.

- Post signs to warn workers about the hazard and to inform them about required protective equipment.

- Provide workers with training that includes information about health effects, work practices, and protective equipment for crystalline silica.

- Report all cases of silicosis to State health departments and to OSHA or MSHA.

These recommendations are discussed briefly in the following subsections.

Initial Assessment

Before mining begins, geological reports and other information should be reviewed to determine the potential for exposing workers to crystalline silica during removal of the overburden.

Air Monitoring

Air monitoring should be performed to measure worker exposure to airborne crystalline silica and to provide a basis for selecting engineering controls. Air monitoring should be performed as needed to measure the effectiveness of controls. Air samples should be collected and analyzed according to NIOSH Method Nos. 7500 and 7602 [NIOSH 1984] or their equivalent.

Engineering Controls

Effective source control measures and good work practices should be implemented to minimize worker exposure to crystalline silica. Examples of control measures include dust-suppression skirts, wet drilling, local exhaust ventilation, and isolation of the worker in enclosed drilling rig cabs with positive-pressure air-conditioning [Volkwein 1988; Stern 1977].

Personal Hygiene

The following personal hygiene practices are important elements of any program for protecting workers from exposure to crystalline silica:

- All drillers should wash their hands and faces before eating, drinking, or smoking.

- Workers should not eat, drink, or use tobacco products in the drilling area.

- Workers should shower before leaving the worksite.

- Workers should park their cars where they will not be contaminated with silica.

Protective Clothing

The following measures should be taken to assure that the drillers’ dusty clothes do not contaminate cars, homes, or worksites other than the drilling area:

- Workers should change into disposable or washable work clothes at the worksite.

- Workers should change into clean clothes before leaving the worksite.

Respiratory Protection

Respirators should not be used as the only means of preventing or minimizing exposures to airborne contaminants. Effective source controls such as dust-suppression skirts, wet drilling, enclosed cabs, local exhaust ventilation, and good work practices should be implemented to minimize worker exposure to silica dust. NIOSH prefers such measures as the primary means of protecting workers. However, when source controls cannot keep exposures below the NIOSH REL, controls should be supplemented with the use of respiratory protection during rock drilling operations.

When respirators are used, the employer must establish a comprehensive respiratory protection program as outlined in the NIOSH Guide to Industrial Respiratory Protection [NIOSH 1987a] and as required in the OSHA respiratory protection standard [29 CFR 1910.134] and in the MSHA standards [30 CFR 56.005, 57.5005, 70 Subpart D]. Important elements of these standards are

- an evaluation of the worker’s ability to perform the work while wearing a respirator,

- regular training of personnel,

- periodic environmental monitoring,

- respirator fit testing,

- maintenance, inspection, cleaning, and storage, and

- selection of proper NIOSH-approved respirators.

The respiratory protection program should be evaluated regularly by the employer.

Table 1 lists the minimum respiratory equipment required to meet the NIOSH REL for crystalline silica under given conditions. Workers should wear the most protective respirator that is feasible and consistent with the tasks to be performed. For additional information about respirator selection, consult the NIOSH Respirator Decision Logic [NIOSH 1987b]. Workers should use only those respirators that have been certified by NIOSH and MSHA [NIOSH 1991].

Table 1.–NIOSH-recommended respiratory protection for workers exposed to respirable crystalline silica

| Condition | Minimum respiratory protection* required to meet the NIOSH REL for crystalline silica (50 µg/m3)** |

|---|---|

| Less than or equal to 500 µg/m3 (10 x REL***) |

Any air-purifying respirator with a high-efficiency particulate filter |

| Less than or equal to 1,250 µg/m3 (25 x REL) |

Any powered, air-purifying respirator with a high-efficiency particulate filter, or

Any supplied-air respirator equipped with a hood or helmet and operated in a continuous-flow mode (for example, type CE abrasive blasting respirators operated in the continuous-flow mode) |

| Less than or equal to 2,500 µg/m3 (50 x REL) |

Any air-purifying, full-facepiece respirator with a high-efficiency particulate filter, or

Any powered, air-purifying respirator with a tight-fitting facepiece and a high-efficiency particulate filter |

| Less than or equal to 50,000 µg/m3 (1,000 x REL) |

Any supplied-air respirator equipped with a half-mask and operated in a pressure-demand or other positive-pressure mode |

| Less than or equal to 100,000 µg/m3 (2,000 x REL) |

Any supplied-air respirator equipped with a full facepiece and operated in a pressure-demand or other positive-pressure mode (for example, a type CE abrasive blasting respirator operated in a positive-pressure mode) |

| Planned or emergency entry into environments containing unknown concentrations or concentrations less than or equal to 500,000 µg/m3 (10,000 x REL) |

Any self-contained breathing apparatus equipped with a full facepiece and operated in a pressure-demand or other positive-pressure mode,**** or

Any supplied-air respirator equipped with a full facepiece and operated in a pressure-demand or other positive-pressure mode in combination with an auxiliary self-contained breathing apparatus operated in a pressure-demand or other positive-pressure mode**** |

| Firefighting | Any self-contained breathing apparatus equipped with a full facepiece and operated in a pressure-demand or other positive-pressure mode**** |

| Escape only | Any air-purifying, full-facepiece respirator with a high-efficiency particulate filter, or

Any appropriate escape-type, self-contained breathing apparatus |

| * Only NIOSH/MSHA-approved equipment should be used. [Return to top of table] ** These recommendations are designed to protect workers from silicosis; only the most protective respirators are recommended for use with carcinogens. [Return to top of table] *** Assigned protection factor (APF) times the NIOSH REL. The APF is the minimum anticipated level of protection provided by each type of respirator. [Return to body of table] **** Most protective respirators. [Return to body of table] |

|

Medical Monitoring

Medical examinations should be available to all workers who may be exposed to crystalline silica. Such examinations should occur before job placement and at least every 3 years thereafter [NIOSH 1974]. More frequent examinations (for example, annual) may be necessary for workers at risk of acute or accelerated silicosis. Examinations should include at least the following items:

- A medical and occupational history to collect data on worker exposure to crystalline silica and signs and symptoms of respiratory disease

- A chest X-ray classified according to the 1980 International Labour Office (ILO) Classification of Radiographs of the Pneumoconioses [ILO 1981]

- Pulmonary function testing (spirometry)

- An annual evaluation for tuberculosis [ATS/CDC 1986].

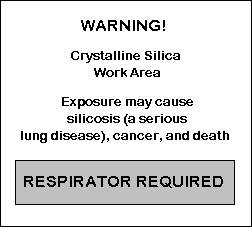

Warning Signs

Signs should be posted to warn workers about the hazard and specify any protective equipment required (for example, respirators). The sample sign in Figure 3 contains the information needed for a silica work area where respirators are required.

Figure 3. Sample warning sign for silica work area requiring respirators.

Training

Workers should receive training [30 CFR 48; 29 CFR 1926.21] that includes the following:

- Information about the potential adverse health effects of crystalline silica exposure

- Material safety data sheets for crystalline silica [29 CFR 1926.59].

- Instruction about obeying signs that mark the boundaries of work areas containing crystalline silica

- Discussion about the importance of engineering controls, personal hygiene, and work practices in reducing crystalline silica exposure

- Instruction about the use and care of appropriate protective equipment (including protective clothing and respiratory protection)

Surveillance and Disease Reporting

NIOSH encourages reporting of all cases of silicosis to the State health departments and to OSHA or MSHA. To enhance the uniformity of reporting, NIOSH has developed reporting guidelines and a surveillance case definition for silicosis (see Appendix). This definition and these guidelines are recommended for surveillance of work-related silicosis by State health departments and regulatory agencies receiving reports of cases from physicians and other health care providers [CDC 1990].

Acknowledgements

Karl Musgrave, D.V.M., and John Parker, M.D., were the principal contributors to this Alert. Comments, questions, or requests for additional information should be directed to Dr. Gregory Wagner, Director, Division of Respiratory Disease Studies, 944 Chestnut Ridge Road, Morgantown, West Virginia 26505-2888; telephone, (304) 291-4474.

We greatly appreciate your assistance in protecting the lives of American workers.

[signature]

J. Donald Millar, M.D., D.T.P.H. (Lond.)

Assistant Surgeon General

Director, National Institute for Occupational Safety and Health

Centers for Disease Control

Notes

* Also referred to as free silica, or SiO2; includes quartz, cristobalite, tridymite, and tripoli. [Return to main text]

** Code of Federal Regulations. See CFR in references. [Return to main text]

References

Ahlman K, Backman A-L, Partanen T [1975]. A health survey of granite workers in Finland: radiographic findings, respiratory function, hearing, electric sensory thresholds of the fingers and subjective symptoms. Scand J Work Environ Health 1:109-116.

Allison AC, Hart PD [1968]. Potentiation by silica of the growth of Mycobacterium tuberculosis in macrophage cultures. Br J Exp Pathol 49:465-476.

Amandus HE, Hanke W, Kullman G, Reger RB [1984]. A re-evaluation of radiological evidence from a study of U.S. strip coal miners. Arch Environ Health 39(5):346- 351.

Amandus HE, Petersen MR, Richards TB [1989]. Health status of anthracite surface coal miners. Arch Environ Health 44(2):75-81.

Amandus HE, Piacitelli G [1987]. Dust exposures at U.S. surface coal mines in 1982-1983. Arch Environ Health 42(6):374-381.

ATS/CDC (American Thoracic Society and Centers for Disease Control) [1986]. Treatment of tuberculosis and tuberculosis infection in adults and children. Am Rev Respir Dis 134(2):355-363.

Bailey WC, Brown M., Buechner HA, Weill H, Ichinose H, Ziskind M [1974]. Silico- mycobacterial disease in sandblasters. Am Rev Respir Dis 110:115-125.

Banks DE, Bauer MA, Castellan RM, Lapp NL [1983]. Silicosis in surface coalmine drillers. Thorax 38:275-278.

Bavley H [1950]. Some environmental aspects in the construction of the city tunnel. Ind Hyg Q 11(2):125-129.

Buechner HA, Ansari A [1969]. Acute silico-proteinosis. Dis Chest 55(4):274- 284.

Burns C, Ottoboni F, Mitchell HW [1962]. Health hazards and heavy construction. Am Ind Hyg Assoc J 23(1):273-281.

CDC (Centers for Disease Control) [1990]. Silicosis: cluster in sandblasters–Texas, and occupational surveillance for silicosis. MMWR 39(25):433-437.

CFR. Code of Federal regulations. Washington, DC: U.S. Government Printing Office, Office of the Federal Register.

Cherniack M [1989]. Hawk’s nest incident: America’s worst industrial disaster. Hartford, CT: Yale University Press.

DHHS [1990]. Healthy people 2000: national health promotion and disease objectives. Washington, DC: U.S. Department of Health and Human Services, Public Health Service, DHHS Publication No. (PHS) 91-50212.

DHHS [1991]. Sixth annual report on carcinogens: summary 1991. Research Triangle Park, NC: U.S. Department of Health and Human Services, Public Health Service, National Institute of Environmental Health Sciences, pp. 357-364.

Ezenwa AO [1982]. Studies of environmental and host factors influencing personal differences in response to industrial silica dust exposure. Ann Occup Hyg 26(1- 4):745-752.

Fairman RP, O’Brien RJ, Swecker S, Amandus HE, Shoub EP [1977]. Respiratory status of surface coal miners in the United States. Arch Environ Health 32(1):211-215.

Goodman GB, Kaplan PD, Stachura I, Castranova V, Pailes WH, Lapp NL [1992]. Acute silicosis responding to corticosteroid therapy. Chest 101:366-370.

Guenel P, Breum NO, Lynge E [1989]. Exposure to silica dust in the Danish stone industry. Scand J Work Environ Health 15:147-153.

IARC [1987]. IARC monographs on the evaluation of the carcinogenic risk of chemicals to humans: silica and some silicates. Vol. 42. Lyon, France: World Health Organization, International Agency for Research on Cancer, pp. 49, 51, 73- 111.

ILO (International Labour Office) [1981]. Classification of radiographs of the pneumoconioses. Med Radiogr Photogr 57(1):2-17.

Maksimovic SD, Page SJ [1986]. Quartz dust sources during overburden drilling at surface coal mines. Ann Am Conf Gov Ind Hyg 14:361-366.

Ng TP, Chan SL [1991]. Factors associated with massive fibrosis in silicosis. Thorax 46(4):229-232.

Ng TP, Yeung KH, O’Kelly FJ [1987]. Silica hazard of caisson construction in Hong Kong. J Soc Occup Med 37:62-65.

NIOSH [1974]. Criteria for a recommended standard: occupational exposure to crystalline silica. Washington, DC: U.S. Department of Health, Education, and Welfare, Public Health Service, Center for Disease Control, National Institute for Occupational Safety and Health, DHEW Publication No. (NIOSH) 75-120, pp. 54- 55, 60-61.

NIOSH [1984]. NIOSH manual of analytical methods. 3rd rev. ed. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 84-100.

NIOSH [1987a]. Guide to industrial respiratory protection. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 87-116.

NIOSH [1987b]. Respirator decision logic. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 87-108.

NIOSH [1988]. NIOSH submissions on the OSHA air contaminants standard: testimony of the National Institute for Occupational Safety and Health on the Occupational Safety and Health Administration’s proposed rule on air contaminants. Presented at the OSHA informal public hearing, August 1, 1988. NIOSH policy statements. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health.

NIOSH [1991]. NIOSH certified equipment list as of December 31, 1990. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 91-105.

Owens MW, Kinasewitz GT, Gonzalez E [1988]. Case report: sandblaster’s lung with mycobacterial infection. Am J Med Sci 295(6):554-557.

Parker JE, Lapp NL, Banks DE [1989]. Surface coal mine drillers and silicosis: the ten year West Virginia experience [Abstract]. Am Rev Respir Dis 139:A490.

Peters JM [1986]. Silicosis. In: Merchant JA, Boehlecke BA, Taylor G, Pickett- Harner M, eds. Occupational respiratory diseases. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 86-102, pp. 219-237.

Piacitelli GM, Amandus HE, Dieffenbach A [1990]. Respirable dust exposures in U.S. surface coal mines (1982-1986). Arch Environ Health 45(4):202-209.

Sacharov KM, Knauss KG, Kubala PJ [1971]. Reductions of dust exposures in the slate industry. Am Ind Hyg Assoc J 32(1):119-122.

Silicosis and Silicate Disease Committee [1988]. Diseases associated with exposure to silica and nonfibrous silicate minerals. Arch Pathol Lab Med 112:673-720.

Stern AC, ed [1977]. Air pollution. 3rd ed. Vol. IV. New York, NY: Academic Press, pp. 707.

Tomb TF, Peluso RG, Parobeck PA [1986]. Quartz in United States coal mines. Ann Am Conf Gov Ind Hyg 14:513-519.

Volkwein JC [1988]. Industrial hygiene from mining research. Research to replace respirators in mining. Appl Ind Hyg 3(11):F8, F10.

Ziskind M, Jones RN, Weill H [1976]. Silicosis. Am Rev Respir Dis 113:643-665.

Appendix

Surveillance Guidelines For State Health Departments: Silicosis *, **

Reporting Guidelines

State health departments should encourage physicians, including radiologists and pathologists, as well as other health-care providers, to report all diagnosed or suspected cases of silicosis. These reports should include persons with:

A. A physician’s provisional or working diagnosis of silicosis OR

B. A chest radiograph interpreted as consistent with silicosis OR

C. Pathologic findings consistent with silicosis

State health departments should collect appropriate clinical, epidemiologic, and workplace information on persons reported with silicosis as needed to set priorities for workplace investigations.

Surveillance Case Definition

A. 1. History of occupational exposure to airborne silica dust** AND

A. 2. Chest radiograph or other imaging technique interpreted as consistent with silicosis,*** OR

B. Pathologic findings characteristic of silicosis****

Notes to the Appendix

* Reprinted from CDC [1990], p. 436. [Return to top of appendix]

** Exposure settings associated with silicosis are well characterized and have been summarized in several reviews [Ziskind et al. 1976; Peters 1986]. The induction period between initial silica exposure and development of radiographically detectable nodular silicosis is usually 10 years. Shorter induction periods are associated with heavy exposures, and acute silicosis may develop within 6 months to 2 years following massive silica exposure. [Return to top of appendix]

*** Cases can be classified as simple or complicated. Simple silicosis is present if the largest opacity is less than 1 cm in diameter. Complicated silicosis (also known as progressive massive fibrosis [PMF]) is present if the largest opacity is greater than or equal to 1 cm in diameter. Common radiographic findings of nodular silicosis include multiple, bilateral, and rounded opacities in the upper lung zones; other patterns have been described. Since patients may have had mixed dust exposure, irregular opacities may be present or even predominant. Radiographs interpreted by NIOSH-certified “B” readers should have profusion categories of 1/0 or greater by the International Labour Organization classification system [ILO Committee on Pneumoconiosis 1981]. A bilateral alveolar filling pattern is characteristic of acute silicosis and may be followed by rapid development of bilateral small or large opacities. [Return to body of appendix]

**** Characteristic lung tissue pathology [Silicosis and Silicate Disease Committee 1988] in nodular silicosis consists of fibrotic nodules with concentric “onion-skinned” arrangement of collagen fibers, central hyalinization, and a cellular peripheral zone, with lightly birefringent particles seen under polarized light. In acute silicosis, microscopic pathology shows a periodic acid-Schiff positive alveolar exudate (alveolar lipoproteinosis) and a cellular infiltrate of the alveolar walls. [Return to body of appendix]

Preventing Silicosis and Deaths in Rock Drillers (Worker/Employer Summary Sheet Only)