Window Cleaner Killed in Fall Due to Unsecured Line

Oregon Case Report: 05OR038

October 10, 2006

Summary

On October 19, 2005, a 31-year-old Hispanic window cleaner was killed when he fell six stories from a balcony on a seven-story commercial building. The window cleaner and a coworker had rigged their descent lines, safety lines, and boatswain’s chairs, and attached the equipment to wire cables strung between roof anchors. The window cleaner, who was the designated supervisor of the team, got into his boatswain’s chair, and climbed over the balcony edge. The coworker saw the window cleaner falling, and then saw one end of his safety cable fall off the roof of the building. The coworker immediately rappelled down to assist the victim, who had landed on the concrete walk below. The coworker dialed 911 on his cell phone and was assisted with the call by an off-duty paramedic, who witnessed the event. An emergency medical team arrived minutes later. The victim died instantly in the fall.

|

| Two certified anchor points are visible here on the roof of the building where the incident occurred. The victim’s anchor line was not attached to the left anchor. |

Recommendations

- Workers at suspended heights must inspect the condition and security of all anchors, rigging, and other equipment prior to use.

- Workers at suspended heights should cooperate to double check the security of all rigging, and communicate readiness to proceed.

- Employers must maintain a written fall-protection safety program to document that workers at suspended heights are properly trained and proficient in safe work procedures.

Introduction

On October 19, 2005, a 31-year-old experienced Hispanic window cleaner, preparing to clean windows on a commercial building, fell 72 ft to his death. OR-FACE was notified of the incident on the same day. An OR-FACE investigator interviewed the employer on November 9, 2005. The coworker was unavailable for an interview. This report is based on the OR-FACE investigation, and Oregon OSHA, medical examiner, and media reports.

The employer had been a window cleaner since 1969 and had opened his own business in 1992, specializing in cleaning exterior and interior commercial building windows. At the time of the incident, he had three workers, two workers for high-rise window cleaning using boatswain’s chairs and ropes, and another worker for lower windows using ladders, aerial lifts, and scaffolds. The employer reported hiring only journeymen cleaners. Hiring was based on work applications that stated previous cleaning experience with local firms, and a single observation in setting up rigging.

The employer did not have a window cleaners training or safety program, and did not hold safety meetings. Workers were responsible for maintaining their own equipment and reporting problems and equipment needs. The employer reported that he bought new ropes yearly, and used the previous year’s ropes as lifelines. The employer visited the job sites only to deliver workers and supplies.

The window cleaner in this incident, who spoke both English and Spanish fluently, was hired in February 2005. He and his high-rise coworker had worked together at another firm for 3 years. Both men worked second jobs in the evenings at a fast food restaurant. The victim had a good work history for safety, and was made a supervisor 3 months after being hired.

Investigation

On the morning of the incident, the two window cleaners arrived at 6:30 a.m. at the seven-story commercial building. The time was 2 hours before sunrise, and they set up their rigging lines in the dark. Equipment consisted of safety cables for the anchor points, half-inch wire ascent/descent cables, lifelines, two ropes, screw-type carabiners (called “D-rings”), a descender and rope grabber, safety harness, and boatswain’s chair.

The window cleaner connected one end of his wire anchor cable with a D-ring to a fixed roof anchor and stretched the cable around a 90-degree angle of the roof line to a second fixed roof anchor, where he apparently laid the end of the cable next to the anchor without attaching it. The closed D-ring for the anchor was later found 30 ft away from the anchor, apparently unused.

|

| The one secured anchor line dangled over the roof edge following the incident. |

The coworker set up his own anchor cables to roof anchors farther down the roof line, and rigged his own lines. Both cleaners put pieces of carpeting over the parapet to protect the ropes from being chafed by the roof edge. The window cleaners gained access to the exterior of the building from a balcony on the sixth floor. Next to each other on the same balcony, each window cleaner attached a boatswain’s chair to his own anchor cable, donned a safety harness, and climbed onto a window box to descend over the edge.

The coworker reported that he noticed the window cleaner, who was also his supervisor, attach his boatswain’s chair and lifeline to the same anchor cable, contrary to safe practice, which requires a lifeline to be attached to a completely independent anchor cable. Reportedly, the coworker warned the window cleaner of the problem before their descent, and they were still talking about the rigging’s safety as they went over the edge of the balcony.

|

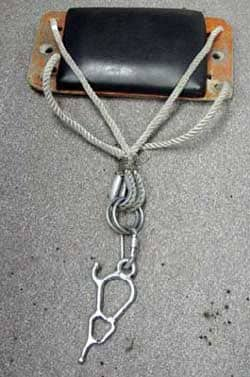

| Detail of a boatswain’s chair shows attachment to a descender with a screw-type carabiner. |

Both workers were careless with their lifelines. The window cleaner’s second anchor cable for the lifeline was later discovered in the window cleaners’ storage room at the site. The coworker had attached his anchor cable for the lifeline to a roof standpipe, and not to a secure anchor point. Detail of a boatswain’s chair shows attachment to a descender with a screw-type carabiner.

Once over the edge, the coworker saw the window cleaner immediately falling. Then he saw one end of the window cleaner’s anchor cable come off the top of the building. The victim landed on the concrete below and was instantly killed. The coworker rappelled down to the ground, found the victim unresponsive, and dialed 911 on his cell phone. An off-duty paramedic, who witnessed the event and ran over to help, completed the emergency call. An emergency medical team arrived minutes later.

Cause of Death

Multiple head, chest and extremity injuries.

Recommendations/Discussion

Recommendation #1: Workers at suspended heights must inspect the condition and security of all anchors, rigging, and other equipment prior to use.

Working while suspended from a height is extremely hazardous and deserves extraordinary attention to safety. An insecure or broken primary line is the cause of most worker falls from suspended heights. Reported fatalities often involve a personal lifeline incorrectly attached to the same anchor line as in this incident, or not used at all.

The following points represent basic safety concerns for window cleaners as highlighted by this incident.

- Building owners must install and regularly test certified anchor points for suspension work, and ensure that window cleaners are aware of their locations. Window cleaners should not use an inappropriate anchor that merely looks strong, such as an air conditioning unit, roof pipe, or balcony rail. Window cleaners should communicate to the building owner any deterioration of an anchor that makes it unsuitable for use.

- A primary line should be attached to a single anchor point. This incident illustrates the increased risk when a line is strung between two anchor points.

- A personal lifeline must be worn and secured to a completely independent anchor point.

- Suspension lines should not be strung around corners. An extra corner reduces the load capacity of a line significantly and increases the chance of breaking from sudden force. A roof edge should be padded to prevent damage to the ropes.

- The condition of all ropes and equipment must be inspected prior to each use. Even small signs of wear can cause friction that may lead to an unexpected break or release.

- Make sure to use adequate lighting when making all rigging connections. Early morning hours in the dark can easily conceal a mistake.

- Test the security of all lines prior to use. Employ caution while testing to avoid losing your balance or falling in the event a line fails.

|

Recommendation #2. Workers at suspended heights should cooperate to double check the security of all rigging, and communicate readiness to proceed.

This incident emphasizes the importance of double checking the security of anchors and lines, and following positive communication procedures with coworkers before taking the first step over the edge. Rigging or re-rigging of primary anchor lines should be checked by both members of a team, and readiness should be verbalized as a positive check before proceeding. A preliminary “tool box” meeting is highly recommended to confirm that all rigging is secured and tested prior to use. As this incident makes clear, disagreements should be settled before workers step over the ledge.

Safety guidelines for both working and recreational climbing teams rely heavily on the expertise of a designated leader or competent person to maintain adequate safety standards for the whole team. This incident indicates that other team members share a responsibility to check and communicate safety requirements, and the leader shares a responsibility to listen.

Recommendation #3. Employers must maintain a written fall protection safety program to document that workers at suspended heights are properly trained and proficient in safe work procedures.

A window-cleaner safety training and inspection program will promote worker competence and the use of safe work procedures, with continuing supervision and retraining when necessary. A written safety program and training record helps to maintain standards and promotes accountability for both employer and employees. Certificate programs for window cleaners are available in both English and Spanish (e.g., International Window Cleaner Certification Institute).

This incident highlights a few essential points in a training program for window cleaners.

- Recognize fall hazards.

- Understand how to use and maintain fall-protection systems, including use of appropriate anchor points, and inspection of equipment.

- Know what to do in an emergency to ensure a prompt response. The employer must develop a written rescue plan in advance (templates are available as a guide).

References

- Construction Safety Magazine. (2004). Fall-arrest rescue [emergency response template]. Available online (p. 7): http://66.203.200.8/UploadFiles/Magazine/43676_Wint2004.pdf (Link no longer valid)

- Health and Safety Executive. (2006). Falls from height. Online resource [UK]: http://www.hse.gov.uk/pubns/fallindx.htm

- Oregon OSHA.(2006). Fall protection for the construction industry [ Pub 440-2824]. Available online: http://www.cbs.state.or.us/external/osha/pdf/pubs/2824.pdfFatality Assessment and Control Evaluation investigation reports:

- Massachusetts FACE. (2006). Two window washers fall 90 feet when their horizontal static line failed [03MA010]. Available online: https://www.cdc.gov/niosh/face/stateface/ma/03ma010.html

- Massachusetts FACE. (2006). Massachusetts window washer dies in six floor fall from a ten floor building [93MA014]. Available online: https://www.cdc.gov/niosh/face/stateface/ma/93ma014.html

- Minnesota FACE. (2006). Window washer dies after falling 35 feet when suspension scaffold collapsed [95MN055]. Available online: https://www.cdc.gov/niosh/face/stateface/mn/95mn055.html

- Ohio FACE. (2006). A window washer died as the result of a 40-foot fall from the roof of a three-story building [99OH063]. Available online: https://www.cdc.gov/niosh/face/stateface/oh/99oh063.htm

- Washington FACE. (2002). Fifteen-year- old worker falls from roof of building in Washington state [98WA113]. Available online: https://www.cdc.gov/niosh/face/stateface/wa/98wa113.html

Oregon FACE Program

To contact Oregon State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

CROET at OHSU performs OR-FACE investigations through a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research. The goal of these evaluations is to prevent fatal work injuries in the future by studying the work environment, the worker, the task, the tools, the fatal energy exchange, and the role of management in controlling how these factors interact.

Oregon FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.