Worker Crushed by Tanker

Nebraska FACE Investigation 00NE005

SUMMARY

A 50-year-old feed lot manager was killed when he was crushed between the top of a tanker and an overhead steel beam. The tanker had liquid steer food (molasses) in it. The tanker was divided into four compartments for carrying liquid. The front compartment was full, the two middle compartments were empty and the victim had just emptied the rear compartment. He climbed up a ladder on the rear of the tanker to look into the rear tank to ensure it was empty. The weight of the molasses in the front tank caused the tanker, which was not connected to a truck but was resting on its support leg, to tip forward. The rear of the tanker tipped up and crushed the victim between the tanker and an overhead steel beam. The victim was declared dead at the scene.

The Nebraska Department of Labor Investigator concluded that to prevent future similar occurrences employers should:

- ensure manufacturer’s load limits are not exceeded when using equipment.

- develop, implement and enforce a comprehensive safety program that includes, but is not limited to, training in all hazard identification, avoidance, and abatement.

PROGRAM OBJECTIVE

The goal of the Fatality Assessment and Control Evaluation (FACE) workplace investigation is to prevent work-related deaths or injuries in the future by a study of the working environment, the worker, the task the worker was performing, the tools the worker was using, and the role of management in controlling how these factors interact.

This report is generated and distributed solely for the purpose of providing current, relevant education to employers, their employees and the community on methods to prevent occupational fatalities and injuries.

INTRODUCTION

On March 3, 2000, at approximately 8:50 a.m., a 50-year-old feed lot manager was killed when he was crushed between the top of a tanker and an overhead steel beam. The Nebraska Department of Labor became aware of the fatality on March 3, 2000 by a phone call from the feed lot owner. The Nebraska FACE Investigator conducted a site visit on April 14, 2000, and also spoke with law enforcement personnel who responded to the incident.

The feed lot where the incident occurred has been in business for 30 years. The feed lot employs four individuals. The victim had been employed by the feed lot for 10 years. The feedlot did not have a written safety program and this was the first fatality in its history.

INVESTIGATION:

On the morning of the incident, the victim began work at approximately 7:00 a.m. At the time of the incident, approximately 8:50 a.m., he had just transferred molasses from the rear compartment of the tanker truck to a tank located on a structure above the rear of where the tanker was parked (See figure 1). The molasses is mixed with grain from a bin located on this structure and loaded into trucks and taken and fed to cattle.

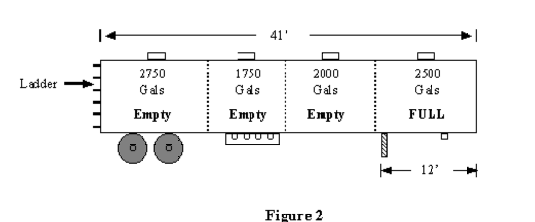

The tanker is 41′ long, 10½’ high, 8′ wide, and has four compartments for holding liquid. At the time of the incident the front tank was full of molasses, the middle two tanks were empty and the rear tank had just been emptied (See figure 2). After emptying the rear tank the victim climbed up the ladder at the rear of the tanker to ensure the tank was empty. The weight of the molasses in the front tank caused the tanker, which was not connected to a truck but resting on its support leg, to tip forward. This caused the rear of the tanker to tip upward, crushing the victim between the tanker and a steel beam that was part of the structure supporting the grain bin and the molasses tank, to which the molasses had been pumped (See figure 3).

Emergency personnel were immediately called and responded to the site. I spoke with a state trooper who was the first responder to the incident. He said when he arrived, the rear of the tanker was in the air and the victim was lying on the top of the rear compartment with his head in the rear tank. He said others in the area saw the tanker pivoting up but there was nothing they could do. Other workers on site used a front end loader to raise the front of the tanker off the ground so EMTs could gain access to the victim. They attempted CPR, but to no avail. The victim was pronounced dead at the scene.

The stainless steel tanker was built by Pullman Trailmobile and was rated for a maximum load of 56,000 pounds and a maximum capacity of 9,000 gallons. I called the company and spoke with an individual who had been with the company for more than 30 years. He stated the company quit making this particular tanker in 1980 and that this model was probably built in 1980. It was designed to transport gasoline. The weight of gasoline typically varies between 5.9 to 6.5 pounds per gallon. The weight of this tanker empty is estimated to be 9,700 lbs. If the front compartment (capacity 2,500 gallons) had been filled with gasoline (assume a weight of 6.5 lbs./gal) the weight of the gasoline would be 16,250 lbs. However, the front compartment was filled with molasses which weighs approximately 11 lbs./gal. Thus, the weight of the molasses would be 27,500 lbs. The tanker resting on the support leg was like a teeter-tooter. When the victim climbed up the rear ladder and moved toward the center of the tanker, the weight shifted toward the fulcrum (the support leg) and caused the front of the tanker with the full compartment to tip toward the ground, which in turn caused the rear of the tanker to tip up, crushing the victim against the overhead steel beam.

CAUSE OF DEATH

The cause of death, as stated on the death certificate, was “victim trapped between beam and tractor trailer.” Massive crushing injuries were present.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure manufacturer’s load limits are not exceeded when using equipment.

Discussion: The trailer involved in this incident was originally designed to transport gasoline and had a posted maximum load of 56,000 pounds. If the trailer had all four compartments full of molasses (9,000 gallons at 11 lbs/gal) it would have a load of 99,000 pounds. This would exceed manufacturer’s requirements and could also pose a safety hazard during transport. The fact that the front compartment had molasses instead of gasoline was most likely a causal factor in the tanker tipping forward. A representative from the trailer manufacturer said using the tanker for molasses should not pose a problem provided the weight limits were not exceeded for each compartment. Recommend the tanks only be filled halfway, when transporting molasses, and that a warning be put on the tanker stating this restriction.

Recommendation #2: Employers should develop, implement, and enforce a comprehensive safety program that includes, but is not limited to, training in all hazard identification, avoidance, and abatement.

Discussion: Research has indicated that workers in agricultural occupations are at increased risk for serious injury and death in the workplace. Training in recognizing and avoiding hazards should be given to all workers, regardless of the number of workers/employees. Written procedures for tasks such as loading and unloading a liquid tanker, loading and unloading grain and entry into grain storage structures should be developed for operations such as a feedlot. All personnel performing these tasks should be trained in these procedures.

To contact Nebraska State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.