Massachusetts Self-Employed Farmer Killed When a Corn Chopper Head Attachment For a Forage Harvester Falls Onto Him

Massachusetts FACE 00-MA-014

SUMMARY

On March 5, 2000, a 56-year-old male self-employed farmer (the victim) was fatally injured while repairing a corn chopper head attachment for a forage harvester. He was repairing the skid on a corn chopper head attachment when it tipped and struck him in the back with one of the tongs before falling on him. The victim was working alone in the garage of a construction company owned by his brother in-law. After failing to reach the victim on his cell phone, his wife went to the garage where she knew he would be working. She found her husband inside the garage not breathing with the corn chopper head attachment on top of him. She immediately placed a call for emergency assistance. The medical examiners office was contacted and, upon arrival, pronounced the victim dead. The Massachusetts FACE Program concluded that to prevent similar occurrences in the future, farmers, including self-employed, should:

- should attempt to leave forage harvester attachments (such as corn chopper heads), connected to the forage harvester during minor repairs

- ensure that proper equipment is used to stabilize machine parts during repair procedures and that the center of gravity of the parts to be repaired is taken into account

- should develop and use a safety checklist to evaluate and prevent hazards before beginning tasks

INTRODUCTION

On March 6, 2000, the Massachusetts FACE Program was notified by a police department through the 24 hour Occupational Fatality Hotline, that on March 5, 2000, a 56-year-old self-employed male farmer had been fatally injured when a corn chopper head tipped and struck him in the back. An investigation was immediately initiated. On April 5, 2000, the Massachusetts FACE Program Director traveled to the incident site where the construction company owner and also brother in-law of the victim was interviewed. The death certificate, OSHA fatality/catastrophe report, photographs of a corn chopper head and backhoe, and corporate information on corn choppers was obtained during the investigation. OSHA had determined that the victim was self-employed and that this fatality did not fall under their jurisdiction and forwarded some information that was collected to the Massachusetts FACE Program.

The victim was employed full-time during the week as a superintendent for a local construction company that his brother-in-law owned. At night and on weekends, the victim tended a farm that he had owned for 15-years. It was unknown if he had a health and safety plan for his farming business, but he had some knowledge of health and safety principles from working at the construction company. The construction company had a comprehensive health and safety program in place and provided equipment training for the employees, which was updated annually.

INVESTIGATION

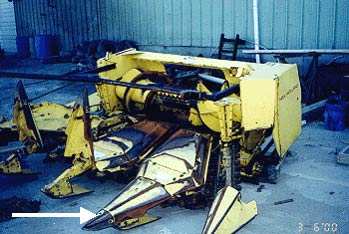

The machinery involved in the incident was a corn chopper attachment (figure 1) for a self-propelled forage harvester. The corn chopper head was used for cutting corn stocks during harvesting and was attached to the front of a forage harvester. One end of the corn chopper head attachment had five triangle-shaped tongs. The pointed ends of the tongs faced forward creating four locations for four corn stock rows to enter. The tongs, which were hinged, also acted as covers for the skids and could be swung up to reveal the skids. The corn chopper head slid across the ground partially on the skids.

When harvesting, corn stocks are cut at their base as they enter the chopper. The stocks, ears, and leaves are chopped and cut into a desirable product size. The product is then corralled into a shoot, which empties into a large truck beside the forage harvester.

During the weekend of March 5, 2000, the victim was working alone (at the construction company’s garage) repairing his corn chopper head attachment. The repair involved spot welding some of the skids.

The victim had positioned the corn chopper head, which was unattached from the forage harvester, approximately 12 feet inside the garage by the overhead door entryway. The floor near the entryway had a slight incline towards the opening. The corn chopper head was positioned on two wooden crib blocks with the tongs pointing upwards. The crib blocks raised the corn chopper head approximately 6 inches off the ground. No additional supports were used to stabilize the chopper head even though it weighted more than a ton and was approximately 9½ feet long and 8 feet wide (including the length of the tongs).

It appeared that the victim was finished welding and was going to move the corn chopper head out of the garage using a backhoe, which belonged to the construction company. He had cleared away the tools used to perform the repair, and positioned the front-end loader bucket of a backhoe inside the garage near the front of the corn chopper head. The bucket of the loader was tilted down and raised approximately 5 feet from the ground. A chain was placed around the bucket in preparation to move the corn chopper head out of the garage. Although un-witnessed, evidence indicates that the corn chopper head may have tipped over (towards the incline of the garage floor by the entryway to the garage door) and struck the victim in the back causing him to fall to the floor. The corn chopper head struck the grille of the backhoe as it fell onto the victim.

After trying to reach the victim on his cell phone, his wife went to the garage where she found him under the corn chopper head and called for emergency assistance. The local police department, state police, and emergency medical personnel responded to her call. In addition, the construction company owner (brother in-law arrived of the victim) arrived soon after rescue personnel were notified. The medical examiners office was later contacted and upon arrival at the site, pronounced the victim dead.

CAUSE OF DEATH

The medical examiner listed the cause of death as traumatic asphyxia.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Farmers, including self-employed, should attempt to leave forage harvester attachments (such as corn chopper heads), connected to the forage harvester during minor repairs.

Discussion: Many maintenance procedures that a corn chopper head requires, such as welding a skid, can be performed while attached to the forage harvester. Leaving the corn chopper head attached to the forage harvester would eliminate the hazard of positioning the corn chopper head in a stable position and location once detached from the harvester.

Recommendation #2: Farmers, including self-employed, should ensure that proper equipment is used to stabilize machine parts during repair procedures and that the center of gravity of the parts to be repaired is taken into account.

Discussion: When moving and working on, a large piece of equipment, such as a corn chopper that is detached from the forage harvester, consideration should be given to the center of gravity of that object. Positioning an object without considering the center of gravity might cause it to be unstable. Once consideration is given to the center of gravity and the object is moved, appropriate physical supports should be implemented to further minimize unexpected movement including tipping.

Appropriate equipment for stabilizing a corn chopper head while unattached from the forage harvester would include large jack stands that could support the weight and handle the size of the corn chopper head. In addition, braces and physical supports made of wood or metal should be used to ensure the stability of the corn chopper. The braces should be kept in place until the corn chopper head is reattached to the forage harvester or is placed securely on the ground.

Recommendation #3: Farmers, including self-employed, should develop and use a safety checklist to evaluate and prevent hazards before beginning tasks.

Discussion: It was unclear if the victim had a written safety program at the time of the incident. A safety program for a self-employed farmer should include precautions to consider before the start of tasks. In addition to the checklist, a more specific hazard analysis should be performed prior to starting each task. Once hazards are identified, the appropriate controls for these hazards should be implemented.

The Newfoundland and Labrador Federation of Agriculture has developed a farm health and safety checklist which is available at http://www.nlfa.ca/ (Link updated 9/12/2005). The checklist contains a series of questions divided into farm health and safety categories with an interpretation guide to help interpret responses given for each question. Two additional farm health and safety documents are also available “How does safety rate on your farm” (http://www.nasdonline.org/document/1673/d001554/how-does-safety-rate-on-your-farm.html) (Link updated 10/5/2009) developed by the Farm Safety Association and “Farm Safety” (www.cdc.gov/niosh/nasd/docs2/oal4900.html – Link no longer valid, 9/12/2005) developed by the U.S. Department of Labor.

REFERENCES

University of Maine Cooperative Extension, Bulletin #2334, Miscellaneous Farm Machinery Safety, Dawna L. Cyr and Steven B. Johnson, Ph.D.

Newfoundland and Labrador Federation of Agriculture, The Farm Health and Safety Project, The Farm Health and Safety Checklist, located at http://www.nlfa.ca/ (Link updated 9/12/2005)

Farm Safety Association, How does safety rate on your farm?, located at http://www.nasdonline.org/document/1673/d001554/how-does-safety-rate-on-your-farm.html (Link updated 10/5/2009)

U.S. Department of Labor, Farm Safety, located at www.cdc.gov/niosh/nasd/docs2/oal4900.html (Link no longer valid, 9/12/2005)

Figure 1 – Corn Chopper Head Disconnected from Forage Harvester

(The arrow points to a tong. The tong to the left of the arrow is raised exposing the skid.)

Figure 2 – Welded Skid of the Corn Chopper Head

(The arrow points to the weld on a skid.)

Figure 3 – Backhoe Used to Lift Corn Chopper Head

To contact Massachusetts State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.