Overturn of a Tractor with ROPS Folded Down Kills Operator

Iowa Case Report: 03IA072

Report Date: June 17, 2005

Summary

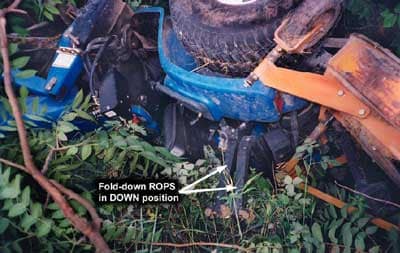

During the summer of 2003, a 23-year-old Hispanic worker, hired by a labor contractor to work for a large hog confinement operation, was killed while in transit from one farm location to another. He was driving a compact utility tractor, which had a front-end loader and a rotary mower attached to the rear. He was familiar with the tractor, having used it for chores around the farm. Normally, workers were required to use their own vehicles for commuting between farm locations, but the tractor was available and was used this time. While driving down a gravel road early in the morning, he evidently lost control and veered into the right-side ditch, where the tractor rolled over ¾ of one revolution (Photo 1). The operator was found dead by a coworker, pinned to the ground by the left rear tire. This tractor was about seven years old and was equipped with a foldable Rollover Protective Structure (ROPS). The ROPS was not in the upright position at the time, and provided no protection for the operator in the overturn (Photo 2). The operator was not wearing a seatbelt, and was thrown from the tractor when it rolled. There were no known environmental factors that contributed to this incident.

|

|

Photo 1 – Side view of the tractor in a roadside ditch after the overturn.

|

Recommendations based on our investigation are as follows:

- Operators should return retractable ROPS (foldable or telescoping) to their upright and locked position immediately upon exiting a low clearance environment where the ROPS must be down.

- Employers should provide training for employees on the correct use of seatbelts on tractors with foldable ROPS.

- Farm owners/operators should provide a safe and healthy working environment, and monitor the safety of workers at their premises, even if the workers are technically employees of a labor contractor.

- Tractor and ROPS manufacturers should consider means which alert operators who are initiating operations with a tractor with ROPS folded or telescoped down.

Introduction

During the early summer 2003, a worker for a large swine confinement operation was killed in a tractor overturn in south-central Iowa. The Iowa FACE program became aware of this incident several months later during a case review provided by the Iowa Department of Labor, and began an investigation at that time. Information was gathered from the County Sheriff, the Iowa State Patrol, Iowa OSHA, and the medical examiner. Photographs were obtained from authorities. A site visit was not conducted because the farm had new ownership and management. The tractor and personnel involved at the time of the incident could not be located.

|

|

Photo 2 – Upside down tractor in the ditch, with foldable ROPS in the down position. Notice the mud around the hinge area from digging into the ground during overturn.

|

The victim was hired by a labor contracting company that supplied workers for the large hog and egg producer, who had multiple farm locations in Iowa and other states. The labor contracting company had been in business for about 10 years, and had approximately 300 workers at the time of this incident. The victim was a laborer assigned to work at hog breeding and farrowing units. He worked full-time with coworkers and a bilingual farm supervisor.

The labor contracting company had a dedicated safety person on staff, and provided safety education for their employees. Safety meetings were quarterly, and more frequently if problems persisted or recurred. Many of the workers were Hispanic, and safety training was taught in Spanish and English by the bilingual farm supervisor. At the time of this incident, all safety manuals were written in English, but were subsequently written in Spanish as well. Animal handling and specific machine safety training were conducted by this same supervisor, who also periodically tested employees for competence. The victim was not officially trained to use the tractor involved in this incident, nor did he have permission to drive the tractor between farm locations on the morning of the incident.

The labor contractor and the farm operation had previously been cited for health and safety, immigration, and overtime pay violations at other production sites. The labor contractor was fined by OSHA in this case for having no Slow Moving Vehicle (SMV) emblem on the tractor, providing no training for hazardous chemicals at initial assignment, not providing ROPS on all tractors, not providing adequate information on safe operating practices, and not reporting the fatality within eight hours.

Investigation

The victim was 23 year-old laborer for a swine confinement operation located in south-central Iowa. He performed various duties at this swine breeding and nursery enterprise and was part of a four person crew supervised by a supervisor from the same labor contractor. All workers at the time were Hispanic. The supervisor was bilingual. This operation had two animal confinement sites at some distance from each other along a gravel road. Nursery confinements were at the east facility and sow confinements at the west facility. The same employees worked at both sites and commuted between them frequently, usually using their own vehicles (except for supervisors who had company vehicles).

At the time of the incident, the victim was in transit from the nursery to the sow confinement facility. He was driving alone, heading west on the gravel road, using a compact utility tractor which he was familiar with. There was no indication of any other traffic on the gravel road at that time. The incident occurred about 6:40 AM., well after sunrise. The victim apparently lost control of the tractor and it veered into the right-hand ditch (Photo 3). He suffered fatal crushing injuries in the overturn. One of the coworkers arrived on site about 7:00 AM and found the victim dead, pinned under the tractor’s left rear wheel. He went to tell the supervisor, who called 911. The Iowa State Patrol and ambulance arrived quickly, but the victim was dead at the scene. The rollover incident was not witnessed.

|

|

Photo 3 – Incident scene facing east, showing road conditions and path the

tractor traveled into the ditch. |

The tractor in this incident was manufactured in the mid 1990’s. It was a modern compact utility tractor with a diesel engine, about 33 hp (24 kW). The tractor weighed about 2500 lbs (1135 kg) without the loader or attached rotary cutter. The tractor was reportedly in normal operating condition. It had turf-type tires which also appeared to be in good condition. The tractor was equipped with a front-end loader and attached gravel bucket. The bucket was empty, and it was low and close to the ground during the incident, which is beneficial for maintaining a low center of gravity and good visibility to the road ahead. However, the bucket may have limited visibility to the edge of the road just ahead of the front wheels. The tractor also had a rotary mower attached to the rear three-point hitch, a finishing-type rotary mower for cutting maintained areas.

Modern compact utility tractors are designed with a small foot print (short wheel base and narrow wheel track width) for good maneuverability. This may compromise driving characteristics at higher speeds when carrying heavy implements, causing the tractor to become unstable. It is not known what caused the operator to lose control of the tractor and veer into the ditch; nor whether the driving characteristics were a contributing factor. This tractor had power steering and steering wheel tilt and telescoping adjustments, as well as an adjustable seat for different sized operators.

There were no obvious environmental conditions contributing to this fatal injury. The injury occurred about 6:40 AM, about one hour after sunrise. The victim was heading west, with the sun behind him. According to the National Weather Service, the temperature that day was slightly higher than normal (minimum 73°, maximum 93°, and average 83° F; 23°, 34°, 28° C, respectively) with light winds about 15 mph (24 km/h) and no precipitation. The gravel road was straight, relatively level, well maintained, and dry. The early morning hours could be a factor, although it is not known whether the victim was tired. He was last seen by his supervisor the day before in the early afternoon.

Cause of Death

The preliminary report of investigation by the medical examiner listed “suffocation due to trauma” as the probable cause of the accidental death.

Recommendations/Discussion

Recommendation #1: Operators should return retractable ROPS (foldable or telescoping) to their upright and locked position immediately upon exiting a low clearance environment where the ROPS must be down.

Discussion: One of the barriers to increased installation of ROPS has been the complaint that ROPS interfere with using tractors in low clearance situations, such as low buildings and orchards. The manufacturers of tractors and ROPS have responded to this concern by manufacturing fold-down type ROPS, which are very common in newer open-station tractors. A concern remains that the fold down ROPS can easily be left in the down position, and seldom, if ever, returned to the upright position. This fatality, to our knowledge, is the first case in Iowa where a folded-down ROPS was involved in a fatal tractor overturn. Owners and operators must be reminded that leaving the fold down ROPS in the down position renders it ineffective. It must be returned to the upright position after any low clearance work.

Recommendation #2: Employers should provide training for employees on the correct use of seatbelts on tractors with foldable ROPS.

Discussion: All ROPS have maximum effectiveness if the operator also uses a seatbelt, which will restrain the operator and keep him in the safety zone provided by the ROPS. Most tractor fatalities occur in tractors without ROPS, when tractors rollover 180°, and pin the operator to the ground. Many times ROPS are effective at preventing a complete tractor overturn, limiting the overturn to 90°. In this case, had the ROPS been raised and operational, it is possible the tractor would have been limited to rolling over on its right side. The operator would surely have been thrown out of his seat and received injuries, but his chances of survivability would have been greatly increased.

There was no reason to have the ROPS in the folded-down position while driving on this road. Employers should ensure that ROPS are kept in the upright position at all times, except when necessary to have them down. It is unclear whether this ROPS was kept down routinely. Employees should be trained not to use tractors outside low clearance environments unless they have ROPS in the upright position and are wearing the seatbelt.

Recommendation #3: Farm owners/operators should provide a safe and healthy working

environment, and monitor the safety of workers at their premises, even if the workers are technically employees of a labor contractor.

Discussion: The employment arrangement in this case was quite complex. The workers were hired by an Iowa labor contracting company. They worked at a farm site that operated under a separate company name as part of a large scale livestock operation with multiple production sites in Iowa and other states. While the OSHA violations were issued to the labor contractor company that directly hired the employee, larger companies hiring services from labor contractors, or managing sub contracts under their operation, should ensure that contractors provide a healthy and safe workplace for all workers on their premises.

Recommendation #4: Tractor and ROPS manufacturers should consider means which alert operators who are initiating operations with a tractor with ROPS folded or telescoped down.

Discussion: Cars have visual and audible signals reminding the driver and the passengers if front seat occupants are not wearing their seatbelts. These warnings offer an instant reminder to buckle up, and likely contribute to higher seatbelt usage rates. A similar warning signal for the fold-down ROPS could indicate that the ROPS should be returned to the upright position before operating the tractor. As fold-down ROPS become more common, there is a danger that many will be operated with the ROPS down, making overturn protection ineffective. All efforts should be made to ensure that operators realize the danger from using the tractor with the ROPS down.

Iowa FACE Program

Fatality Assessment and Control Evaluation, FACE, is a program of the National Institute for Occupational Safety and Health (NIOSH), which is part of the Centers for Disease Control and Prevention of the U.S. Department of Health and Human Services. Nationally, the FACE program identifies traumatic deaths at work, conducts in-depth studies of select work deaths, makes recommendations for prevention, and publishes reports and alerts. The goal is to prevent occupational fatalities across the nation.

The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE case surveillance and evaluation program and also funds state-based programs in several cooperating states. In Iowa, The University of Iowa through its Injury Prevention Research Center works in conjunction with the Iowa Department of Public Health and its Office of the State Medical Examiner to conduct the Iowa FACE program.

Nationally, NIOSH combines its internal information with that from cooperating states to provide information in a variety of forms which is disseminated widely among the industries involved. NIOSH publications are available on the web at https://www.cdc.gov/NIOSH/FACE/ and from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE also publishes its case studies, issues precautionary messages, and prepares articles for trade and professional publication. In addition to postings on the national NIOSH web site, this information is posted on the Iowa FACE site. Copies of FACE case studies and other publications are available by contacting Iowa FACE, too.

The Iowa FACE team consists of the following specialists from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; John Lundell, MA, Co-Investigator; Murray Madsen, MBA, Chief Trauma Investigator; and Co-Investigator/specialists Risto Rautiainen, PhD, and Wayne Sanderson, PhD, CIH. Additional expertise from the Iowa Department of Public Health includes Rita Gergely, Principal Investigator, and John Kraemer, PA, from the Office of the State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.