Control of Ergonomic Hazards in Commercial Dry Cleaning

1997

DHHS (NIOSH) Publication Number 97-160

Hazard

Ergonomic risk factors increase the threat of injury to the musculoskeletal system of the worker. Musculoskeletal disorders are caused by repetitive motions, awkward postures, excessive reaching, and precision gripping. In the drycleaning industry, ergonomic risks occur during garment transfer, pressing, and bagging. These activities, combined with a high work rate and frequency, may cause physical discomfort and musculoskeletal problems for workers. Disorders can include damage to tendons, muscles, nerves, and ligaments of the hand, wrist, arm, shoulder, neck, and back.

Controls

Several engineering measures and work practices are recommended to control ergonomic hazards during garment transfer, pressing, and bagging activities in commercial dry cleaning.

Work Station Design

- Much of the equipment used in dry cleaning shops is nonadjustable. Redesigning workstations will eliminate the need for excessive reaching and many awkward postures. Some dry cleaning equipment manufacturers are beginning to market adjustable height workstations.

Work Organization

- Frequent rest breaks and worker rotation may be used as a temporary measure to control the hazards of repetitive tasks or when engineering changes are not technically feasible.

Garment Transfer

- Use dry-to-dry drycleaning machines that eliminate garment transfer. In shops with transfer machines, train workers to modify their work techniques by handling no more than 15 to 20 lb of clothing during the transfer operation.

- Modify the workplace to reduce the amount of bending and reaching required by the operator. For example, place the bottom of clothing carts at least 16 in. off the ground; preferably, use clothing carts with spring-loaded bottoms to raise the clothes to 16 in. as the cart is unloaded. Position the cart to reduce reach distances and, consequently, stress on the back and shoulders.

Multi-Press Stations

- Use utility presses that permit vertical and horizontal adjustment at the point(s) of operation.

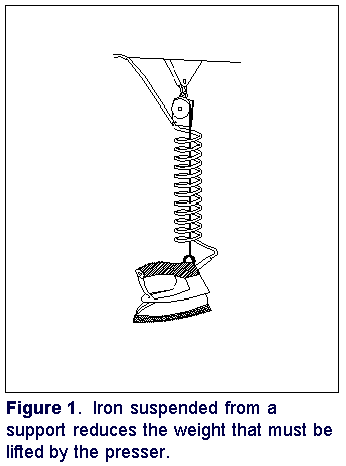

- Place hand iron platforms near the worker to reduce excessive reaching. Attach the iron to a suspension or counterbalancing device to reduce the amount of weight lifted by the presser (Figure 1).

- Use proximity sensors [i.e. infrared, presence sensing devices] instead of two-hand controls to reduce stress on the fingers.

- Use thick (3/8 inch), closed-cell silicone floor mats with a beveled edge to reduce leg fatigue and minimize tripping hazards.

Shirt Pressing Stations

- Position the height of cabinet bag sleever hand controls close to the point of operation to reduce excessive reaching (Figure 2).

- Use proximity sensors instead of dual-hand activation buttons to reduce stress on the worker’s fingers.

- If possible, use a “button pulling” device/tool to aid the worker in pulling the collar button through the buttonhole. This device would reduce the repetitive pinch postures necessary during manual pulling.

Garment Bagging Areas

- Use vertically adjustable bagging poles with a hydraulic pedal control system. Maintain bagging poles in good working condition by ensuring they are straight and lightly lubricated with a non-staining oil.

A NIOSH technical report, Control of Health and Safety Hazards in Commercial Drycleaners: Chemical Exposures, Fire Hazards, and Ergonomic Risk Factors, has been published on this subject. This document is one in a series of seven HAZARD CONTROLS concerning control of hazards in the drycleaning industry that are available free upon request.

*NIOSH is the Federal agency responsible for conducting research and making recommendations for preventing work-related illnesses and injuries. All HAZARD CONTROLS are based on research studies that show how worker exposures to hazardous agents or activities can be significantly reduced.

Acknowledgments

The principal contributors to this publication are Gary S. Earnest, Stephen S. Smith, Lynda Ewers, Avima Ruder, Linda Goldenhar, Daniel S. Watkins, Rosmarie T. Hagedorn, and Jerome P. Flesch.

This document is in the public domain and may be freely copied or reprinted. NIOSH encourages all readers of this HAZARD CONTROLS to make it available to all interested employers and workers.

Control of Ergonomic Hazards in Commercial Drycleaning [PDF – 69 KB]