Exposure to Silica Dust on Continuous Mining Operations Using Flooded-Bed Scrubbers

August 1997

DHHS (NIOSH) Publication Number 97-147

Description of Hazard

Silicosis, a debilitating and potentially deadly lung disease, develops through inhalation of excessive concentrations of respirable crystalline silica dust. In underground coal mines, continuous miner operators have a high risk of overexposure to silica, with approximately 25% of compliance dust samples exceeding the permissible exposure limit. Continuous miners often extract high-silica-content rock from the coal seam or the surrounding strata. Large quantities of silica dust can be generated during cutting and can become entrained in the ventilating air, which can carry the dust to the breathing zones of mine workers. Over the last 15 years, the application of flooded-bed scrubbers (fan-powered dust collectors) on continuous miners has increased as mine operators expand efforts to reduce airborne dust concentrations. During the last several years, the density of the filter media in scrubber filter panels has been reduced to improve scrubber airflow. However, the reduction in filter density suggests that dust collection efficiencies are lower and thus expose mine workers to higher concentrations of respirable silica dust.

Flooded-bed scrubbers capture dust-laden air from the cutting face, carry this air through duct work on the miner, and pass the air through a filter panel that is wetted with water sprays (see Figure 1). As dust particles impact and travel through the filter panel, they mix with water droplets and are removed from the airstream by a mist eliminator. The cleaned air is discharged from the scrubber back into the mine environment. The density and type of media used in a filter panel influence the dust collection efficiency and air-moving capacity of a scrubber. Optimum flooded-bed scrubber performance is achieved when all of the dust-laden air at the cutting face is drawn into the scrubber and a high percentage (+90%) of the respirable dust is removed from this air.

Filter media in the original flooded-bed scrubber design consisted of 40 layers of stainless steel wire mesh secured in a flat filter panel. Panels with pleated filter areas and reduced filter densities were developed to increase the airflow of fixed-capacity scrubbers. Filters containing 30, 20, 15 or 10 layers of stainless steel wire mesh were fabricated. The 20-layer panel is the most common filter now being used. In addition, panels containing filter media other than stainless steel have been developed and are also being used by the coal mining industry.

Recommendations For Prevention

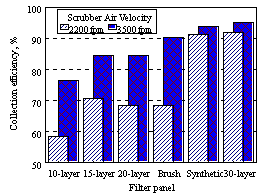

A flooded-bed scrubber test facility was constructed to measure the respirable silica collection efficiency of 10-, 15-, 20- and 30-layer wire mesh filter panels. Two filter panels containing alternative filter media (nonwoven synthetic fiber and an array of nylon brushes) were also evaluated. Operating conditions for both low- and high-capacity scrubbers were evaluated by supplying air velocities of 2,200 feet per minute (fpm) or 3,500 fpm at the scrubber filter. As shown in Figure 2, collection efficiencies of 69% to 84% were obtained with the 20-layer filter. The 30-layer and the synthetic filters had the densest filter media, which resulted in the best silica collection. Efficiencies of 91% to 95% were measured for these panels. The lowest collection efficiencies, 58% to 76%, were found with the 10-layer mesh filter. All filter panels exhibited improved silica collection at the high scrubber air velocity.

Figure 2: Respirable silica collection for scrubber filter panels.

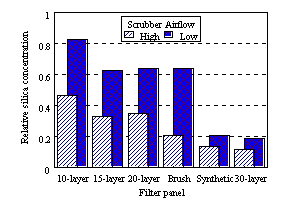

Overall performance of a flooded-bed scrubber depends on the collection efficiency of the filter panel and the amount of ventilating air drawn into the unit. Increasing filter density improved silica collection but also reduced the quantity of air that is drawn through the scrubber. The silica collection efficiency and air-moving capacity of each filter panel were used to determine the relative overall performance of the scrubber. Figure 3 shows the respirable silica concentrations found in the scrubber discharge air with each filter panel. These results indicate that the 30-layer wire mesh panel and the synthetic filter were the most effective in reducing silica dust. Use of the other filter panels resulted in higher concentrations of dust in the discharge air, particularly when simulating low-capacity scrubbers.

Figure 3: Relative silica concentration in scrubber discharge.

On the basis of these findings, NIOSH recommends that the 30-layer stainless steel wire mesh or the synthetic filter panels be used in flooded-bed scrubbers to improve silica collection. Collection efficiency also improved when higher air velocities were present in the scrubber, regardless of the filter panel being tested. The 10-layer wire mesh filter exhibited the poorest performance, and its use should be avoided.

Acknowledgments

The principal contributors to this Hazard Identification are Jay F. Colinet, Mine Safety and Health Division, and Jerome P. Flesch, Education and Information Division, NIOSH.

Exposure to Silica Dust on Continuous Mining Operations Using Flooded-Bed Scrubbers