NIOSH Researchers Develop an Improved Method of Studying Mice

October 2010

DHHS (NIOSH) Publication Number 2010-157

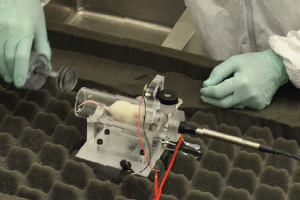

Researcher Vic Johnson (NIOSH) loads a weanling rat into the innovative acoustic plethysmograph.

A Story of Impact:

Breathing-related conditions afflict millions of U.S. workers and cost employers in higher healthcare costs and lost production. The human and financial costs of airway diseases are staggering. For example, while on the job more than 1 in 7 U.S. workers are potentially exposed to materials that can adversely affect their breathing. In addition, airway disease is the 4th leading cause of death in the U.S., claims the lives of nearly 100,000 Americans each year, and costs workers and businesses billions of dollars.

There are a growing number of workplace materials affecting worker health and safety. Exposure to these materials can make it harder for workers to breathe or even cause diseases such as asthma and cancer. These potentially dangerous materials cannot be tested on humans; therefore, researchers rely on animal studies to determine how breathing may be affected.

Mice play a crucial role in this research because they have illnesses similar to humans. Mice may be used to study the impacts that chemical exposure or illnesses have on breathing. Researchers observe and measure such things as how much air flows in and out of a mouse’s lungs, how fast the mouse is breathing, and the mouse’s ability to take in and release air.

Unfortunately, it is often difficult to tell how well a mouse is breathing and how much an airway disease may affect it because some of the measurement techniques have difficulties with the animal subjects. For example, sometimes a mouse is strapped inside a device that causes stress, which can change the way the mouse breathes. An unrestrained mouse can be studied with a different technique; however, these data are limited.

Relevant Information

- Deaths from work-related respiratory diseases and cancers account for about 70% of all occupational disease deaths.

- About 15% of Chronic Obstructive Pulmonary Disease (COPD) results from exposure to hazardous materials in the workplace.

- Work-related asthma is the most common respiratory disease treated in occupational health clinics in the U.S.

Impact

The technique that NIOSH researchers developed uses acoustics to measure how the mouse breathes. The chamber holding the mouse is filled with a controlled sound frequency, which is measured by a microphone. Researchers adjust the air volume in the chamber and create an acoustic resonance that makes it possible to measure small changes in the volume of the mouse, as well as the pressure changes the mouse causes as it breathes. The data collected can be used to estimate how much airway restriction a mouse may have and can give great insight into the breathing process.

This preliminary research has the potential to improve animal studies and benefit countless workers both on and off the job. Additional novel testing methods will also help identify workplace health dangers; lead to safer work practices; and improve the study of airway illnesses, the effects of medicines, and the hazards of workplace materials.

View/Download Entire Document: NIOSH Researchers Develop an Improved Method of Studying Mice [PDF – 401 KB]

![]()

![]()

![]()

![]()