Mining Project: Managing Ground Support for Long-Term Stability in Underground Mines

| Principal Investigators |

|

|---|---|

| Start Date | 10/1/2020 |

| Objective |

To reduce traumatic injuries and fatalities associated with time-dependent physical, chemical, and geologic degradation of excavations and ground support in underground metal mines experiencing squeezing ground. |

| Topic Areas |

Research Summary

In underground metal and nonmetal mines, the underlying issues and mechanisms that degrade ground support systems in squeezing ground are not adequately understood. Methods to identify, monitor, and mitigate the hazards associated with time-dependent closure and support corrosion are needed to prevent ground falls that result in injuries and fatalities. The full potential of these methods will be realized in their adaptability to a wide variety of geologic settings and versatility in changing operational conditions.

Experience has shown that ground/excavation stability deteriorates over time, which can lead to unsafe conditions. Time-dependent processes are often not considered in the design of an underground excavation because they are either not well understood or are too complicated to be considered in a meaningful way. Corrosion of ground support and deformation of ground support due to squeezing conditions are two such examples of time-dependent processes that weaken ground support over time. Conversely, in rockburst-prone ground, the risk of a rockburst is generally understood to decrease over time since the last round advancement, but this is certainly not true for all situations. Similarly, the strength of cemented backfill can increase over time with favorable curing conditions. However, the long-term stability of the backfill may be compromised by chemical attack, ground deterioration, or damage caused by rockbursts.

Although the Mine Safety and Health Administration (MSHA) has instituted new workplace examination policies and emphasizes the need to identify degraded ground support, visual assessments are highly subjective, and industry-accepted protocols do not exist for safely and effectively assessing the severity of degradation in support elements or the competency of in-place backfill. (Please see 2017 - Final Rule.) Several mining companies have requested NIOSH assistance in addressing ground stability problems that involve time-dependent aspects of support degradation, including methods for determining the severity of bolt and mesh corrosion, the integrity of in-place backfill, and the impact of large-scale deformation. Additionally, in the 2019 Mining Program review, recommendations were made for further industry support in the areas of backfill and shotcrete (Please see 2019 - Technical Amendments). The four areas of this proposed research thus include squeezing ground, ground support corrosion, in-place backfill performance, and mining-induced seismicity. These processes are considered time-dependent and represent the least understood aspect (time) in ground support design.

In this project, the four areas of research mentioned above will be addressed by way of the following four research aims:

- Quantify the time-dependent performance of ground support systems and develop predictive guidelines for rehabilitation. This aim will address the most common cause of time-dependent ground support degradation. Squeezing ground deformation is by its nature time-dependent and is a primary cause of ground support failure and the development of unsafe ground conditions. This research aim will explore methods to understand and mitigate the hazards created by movement of ground over time, including most types of rock bolt failure, areal ground support degradation, and excavation failure.

- Characterize corrosion processes for metallic ground support components and gain a better understanding of their detrimental impact on ground support performance. This aim will address the chemical degradation of steel ground support components over time. Corrosion-induced deterioration of ground support is often not apparent at the surface and is often hidden on surfaces that cannot be directly observed. Corrosive conditions can exacerbate pre-existing physical conditions conducive to ground support failure or create wholly new ground control hazards where ground-stress-related factors alone are of little concern. This research aim will investigate methods for assessing and monitoring corrosion potential and the effects for installed ground support.

- Clearly define the safety margins for mine designs utilizing cemented backfill by determining the required engineering properties of the backfill and the subsequent safe spans for various stope configurations or circumstances. This aim addresses time-dependent factors influencing the performance of backfill in supporting the surrounding rock mass or serving in itself as the rock mass. This includes short-term factors (design, placement, curing) long-term factors (hardening, delamination, debonding, flexural failure), and the confining pressure provided by backfill and the stress redistributions caused by strength differentials between the backfill and rock mass. This research aim will seek to improve the long-term performance of backfill through a better understanding of design, placement, new technology, in situ performance, and standardized quality control guidelines.

- Develop more effective seismic energy analysis methods and improve forecasting of induced seismicity around mining areas. This aim addresses the storage of energy in a mining rock mass over time, with particular attention given to the likelihood of sudden energy release from a given portion of the rock mass. Instantaneous releases of this stored energy can create some of the most severe hazards in underground mining, making monitoring of this energy buildup, along with the storage potential of the rock mass, crucial to maintaining a safe mining environment. This research aim will explore seismic modeling options that would improve mining methods and reduce damaging seismic events that would affect the long- or short-term stability of ground support.

The anticipated impacts of the proposed research will be a reduction of ground fall injuries and fatalities, production and dissemination of needed guidance and best practices to industry, technologies and methods for better quantification of ground support system performance over time, and improved standards for manufactured support products.

Measurements or estimates of underground mining equipment impacts or vibrations will be sought.

Milestones and Accomplishments

| Description | Audience | Year |

|---|---|---|

| Evaluated performance benefits of cemented backfill admixtures and reinforcement products. | Ground control professionals at mining operations | 2022 |

| Developed ground control design software that is being used by engineers and students. | Ground control professionals at mining operations; academia | 2022 |

| Evaluated loading characteristics of synthetic skin control meshes relative to steel meshes. | Ground control professionals at mining operations; mesh manufacturers | 2022 |

| Published galvanic corrosion of metal support coupled to graphitic behaving mine rock analysis. | Ground control professionals at mining operations; academia | 2023 |

| Conducted cemented rock fill (CRF) compaction and sample prep study for strength characteristics. Added data added to quality control guidelines studies. | Ground control professionals at mining operations | 2023 |

Outputs

Emery TM, Seymour JB, Sweet DJ, Bourgeois JP, Johnson W, Armatys M [2022]. Effect of binder content on the ductility of cemented hydraulic backfill. In: SME annual meeting, Feb 27-Mar 2, 2022. Society for Mining, Metallurgy, and Exploration, Denver, Preprint No. 22-120

Sweet DJ, Seymour JB, Emery TM, Bourgeois J, Feiler J, M. Gomez M [2022]. Effects of foam additive on the ductility of cemented paste backfill. In: SME annual meeting, Feb 27-Mar 2, 2022. Society for Mining, Metallurgy, and Exploration, Denver, Preprint No. 22-110.

Benton DJ, Sweet DJ, Emery TM [2022]. Comparative analysis of synthetic and steel mesh performance. In Proceeding, 56th US Rock Mechanics & Geomechanics Symposium, June 26-29, 2022, Santa Fe, NM, 8 pp.

Bourgeois J, Emery T, Seymour B, Sweet D, Porter D [2023]. Cemented rockfill size effect study with specific focus on different sample preparation techniques. SME Annual Meeting Feb. 26-Mar. 1, 2023, Denver, CO Preprint 23-046.

Stazick C, Sunderman C, Feagan G [2023]. Galvanic corrosion between graphitic rock and ground support in underground mines. SME Annual Meeting Feb. 26-Mar. 1, 2023, Denver, CO Preprint 23-004.

Supporting Visuals

Synthetic meshes for rock surface control have been tested in the Spokane Mining Research Division (SMRD) High-Energy High-Deformation tester in an effort to quantify synthetic mesh load and energy capacities relative to conventional steel meshes.

Convergence monitoring methods are currently being compared at a partner mine site while advancing a new decline. Comparative study looks to determine relative accuracy and precision of methods in addition to the burden to mine operators.

Size effect studies are being conducted on various backfill materials using conventional and novel preparation methods in order to determine the influence of sample size on measured unconfined compressive strength, and to develop new or improved quality assurance/quality control (QA/QC) methods for operators.

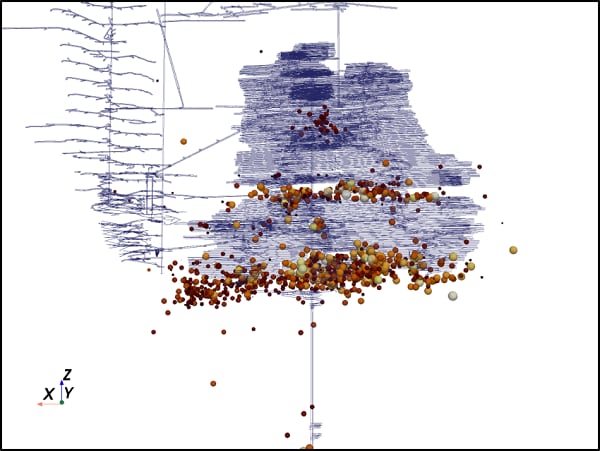

Catalogues of quality seismic data from participating mines are being created to help understand how different mining methods influence the distribution of stresses and seismicity.

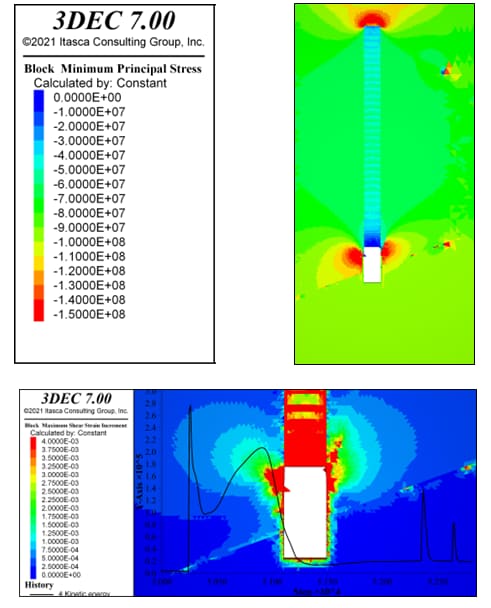

A series of numerical modeling using continuum and discontinuum approaches is being undertaken to research more effective seismic energy analysis methods and to improve forecasting of mining-induced seismicity around mining areas. A mine partner has recently begun utilizing a new underground mining method that has yielded unexpected, but positive, results regarding seismic energy release. These figures show the results of the mining-induced stress and strain energy released, including a dissipated kinetic energy due to the fault zone in the stopes area. These modeling efforts will help the ground control engineers involved in this project better understand how their new mining method can reduce a mining-induced seismic risk potential.

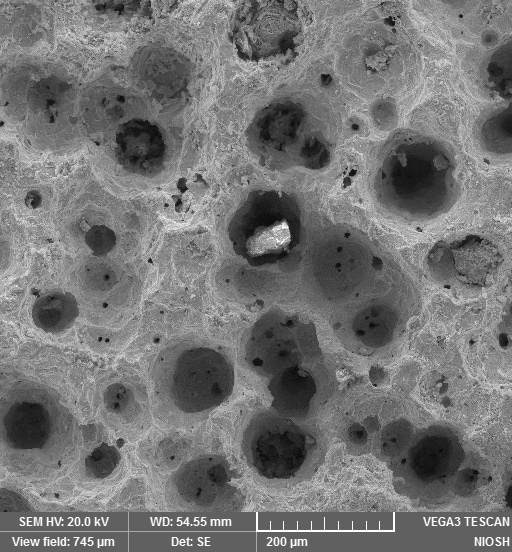

This image shows corrosion pits in metal ground support caused by galvanic corrosion between carbonaceous rock that electrochemically behaves similar to graphite. Laboratory testing was performed that supports that a galvanic coupling can be formed between this rock and metal ground support, as witnessed in two U.S. partner mines.

- Analysis of Multiple Seam Stability

- Damage Delineation in Structures Using Laser Vibrometry and Remote Excitation

- Detecting Strata Fracturing and Roof Failures from a Borehole Based Microseismic System

- Development of Stress Measurements and Instrument Placement Techniques for Longwall Coal

- Local Earthquake Tomography for Imaging Mining-Induced Changes Within the Overburden above a Longwall Mine

- Multiple-Seam Mining in the United States: Background

- Pillar Stability Issues Based on a Survey of Pillar Performance in Underground Limestone Mines

- Pillar Strength and Design Methodology for Stone Mines

- Real-Time Hazard Recognition Using Video Gauge

- Time-Lapse Tomography of a Longwall Panel: A Comparison of Location Schemes