Mining Project: Improving Prevention and Suppression of Equipment Fires in Metal/Nonmetal Mines

| Principal Investigator |

|

|---|---|

| Start Date | 10/1/2019 |

| End Date | 9/30/2023 |

| Objective |

This project evaluated and developed effective measures to prevent hot surface ignitions on mining equipment and improve fire suppression techniques for equipment fires. The project developed a diagnostic tool to identify and evaluate the impacts of mine fires on a mine’s ventilation system. Mine fires remain one of the biggest threats to the health and safety of miners in metal and nonmetal (M/NM) mines. Most of the reportable mine fires are equipment fires caused by ignitions of combustible fluids such as hydraulic fluid released from a hose rupture onto hot engine surfaces. To reduce the number of equipment fires, NIOSH developed effective measures to limit or prevent hot surface ignitions on mine equipment as well as to improve the effectiveness of suppression systems through research. The project reached out to mine operators, fire suppression manufacturers, and the Mine Safety and Health Administration (MSHA), all of which benefited from this work’s advanced design and mitigation techniques. |

| Topic Areas |

Research Summary

Approach

Large-scale experiments in the NIOSH fire test facility determined the minimum hot surface temperatures for the ignition of various fluids commonly used on mining equipment. These fluids included diesel fuel, hydraulic fluid, and engine oil. Such tests assessed the effects of air velocity around the hot surface, the composition of the hot surface material, and fluid type on the occurrence of hot surface ignition. A variable-speed fan was used to control airflow speed. The hot surface materials identified for testing were cast iron alloy, carbon steel, and stainless steel. Hot surface ignition results were presented to the MSHA Approval and Certification Center (A&CC) to help improve equipment fire prevention.

Large-scale experiments conducted in the NIOSH fire test facility were used to evaluate the effectiveness of different fire suppression systems for fires caused by a hot surface ignition. Various fire suppression systems—water mist, dry chemical, wet chemical, dual agent (dry chemical and wet chemical), and carbon dioxide—were installed based on the manufacturers’ guidelines. The effectiveness of the suppression systems was assessed based on whether a fire was extinguished, how long it took to extinguish the fire, and whether a re-ignition occurred after the application of the fire suppressant. Based on experimental results, recommendations were developed for the M/NM mining sector to prevent hot surface ignitions and extinguish mine equipment fires. Large-scale fire suppression tests were conducted to examine the effect of nozzle locations on the suppressive effect of each system. Based on the test results, appropriate fire suppression nozzle locations were identified.

The MATLAB Machine Learning Toolbox was used to develop a predictive/diagnostic tool for assessing the response of an underground mine ventilation system to an equipment fire. Mine ventilation simulations using the MFIRE software were employed to identify a ventilation network’s responses or sensitivities to various anomalies that can impact ventilation flow (i.e., fire). The data from these sensitivity analyses were then used as inputs to train a diagnostic tool to recognize the potential consequences of an equipment fire on ventilation networks. A tool was developed to use network sensitivities as part of a diagnostic tool for identifying the location of an abnormal airflow source. This tool takes the significant airflow changes from the user as input data and provides potential airways as the source locations. The diagnostic tool can also be used to solve for the flow distribution in the network and sensitivity to resistance changes.

Milestones and Accomplishments

| Description | Audience | Year |

|---|---|---|

| Set up a multi-project fire facility to conduct various fire-related experiments | Equipment manufacturers, MSHA, and mine operators |

2019 |

| Developed an approach to determine fire size and location using the post-fire airflow data | Equipment manufacturers, MSHA, and mine operators | 2021 |

| Conducted and evaluated a series of hot surface ignition tests for three metal types, three fuel types, and four airflows | Equipment manufacturers, MSHA, and mine operators | 2020-2021 |

| Conducted and evaluated all the planned engine fire suppression tests | Equipment manufacturers, MSHA, and mine operators | 2023 |

| Developed a software tool to determine the location of an abnormal airflow source | Equipment manufacturers, MSHA, and mine operators | 2023 |

Planned Impacts and Outcomes

This project disseminated recommendations and guidelines for the prevention of hot surface ignitions on mine equipment. The research also provided recommendations on fire suppression system selection and installation for mine equipment through planned publications. It is expected that equipment manufacturers, MSHA, and mine operators will use these recommendations and guidelines to reduce the risk of hot surface ignitions and improve fire suppression system designs for mine equipment. The research findings will help prevent equipment fires by providing a better understanding of controlling parameters. Mine operators will also benefit from the results of this project by having better control of their ventilation networks in cases of an equipment fire emergency or an unplanned flow disturbance caused by an unknown source.

Outputs

Bahrami D, Zhou L [2022]. A novel methodology to locate an abnormal airflow in underground mine ventilation networks. 2022 SME Preprint 22-018, Salt Lake City, February 27-March 2, 2022.

Xue Y, Bahrami D, Zhou L [2022]. Identifying the location and size of an underground mine fire with simulated ventilation data and random forest model. Min Metal Expl 40:1399-1407.

Zhou L, Thomas RA, Yuan L [2022]. Experimental study of improving a mine ventilation network model using continuously monitored airflow. Min Metal Expl 39:887-895.

Zhou L, Bahrami D [2022]. A derivative method to calculate resistance sensitivity for mine ventilation networks. Min Metal Expl 39:1833-1839.

Tang W, Bahrami D, Yuan L et al. [2022]. Hot surface ignition of liquid fuels under ventilation. Min Metal Expl 39:961–968.

Bahrami D, Zhou L, Xue Y, Yuan L [2023]. Determination of underground hazard location using machine learning techniques, CIM Journal 14(1):56-63.

Supporting Visuals

Photo of hot surface experiments in the NIOSH fire facility to determine ignition temperatures of selected fuel types, airflow speeds, and surface material types. This work concluded that the fuel type has a significant effect on ignition temperature, followed by surface material type. Completed all planned engine fire suppression tests to evaluate the efficacy of commonly used suppression systems under various test conditions. This work concluded that the suppressant used plays a major role followed by nozzle location configuration in effectively suppressing the tested fire sources.

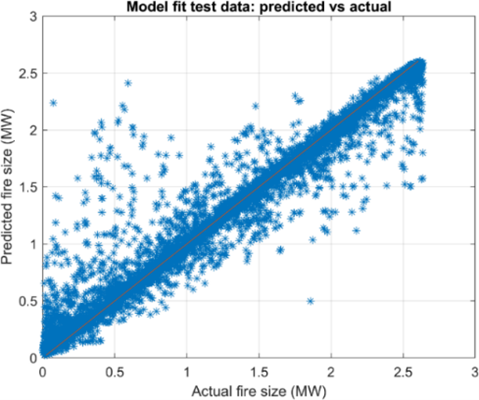

Graphed output from a machine-learning-based diagnostic tool for a mine ventilation network during a mine equipment fire emergency. The NIOSH-developed algorithm proved to be effective in determining fire size and location using airflow data. The algorithm developed to determine the location of an unknown abnormal airflow occurrence in a mine ventilation network proved to be reasonably accurate. This work led to the development of airflow diagnostic tools that enables the user to locate the source of an abnormal airflow event in any mine ventilation network.

- Effectiveness of Various Concentrations of an Inert Gas Mixture for Preventing and Suppressing Mining Equipment Cab Fires: Development of a Dual-Cab Fire Inerting System

- Evaluation of the Bagged Stone Dust Barrier Effectiveness in a Bord and Pillar Mine

- Improvements in Conveyor Belt Fire Suppression Systems for U.S. Coal Mines

- Innovative Strategies for Mine Fire Preparedness

- NIOSH Mine Fire Research in the United States

- Performance-Based Fire Safety Designs for Self-Escape in Underground Mines

- Rapid Detection and Suppression of Mining Equipment Cab Fires

- Technical Solutions for Enhancements to Mine Safety Using Barricade II Fire Blocking Gel

- Testing and Evaluation of an Inflatable Temporary Ventilation Control Device

- Three Coal Mine Ventilation Studies Using Sulfur Hexafluoride Tracer Gas