Mining Project: Design Methodology for Rib Control in Coal Mines

| Principal Investigator |

|

|---|---|

| Start Date | 10/1/2016 |

| End Date | 9/30/2020 |

| Objective |

To reduce the number of rib fall accidents in Eastern U.S. underground coal mines by developing an engineering-based design methodology that defines the appropriate level of rib support. |

| Topic Area |

Research Summary

Sloughed coal rib.

Currently, rib support systems in U.S. coal mines are primarily designed using a trial-and-error approach. 30 CFR and related legislation have not established any minimum design requirements for rib control systems. Because of this lack of a minimum rib control requirement in underground coal mines, the coal mining industry continues to suffer from rib-related injuries and fatalities. During the ten-year period of 2010 through 2019, 17 fatalities caused by rib falls were documented by the Mine Safety and Health Administration (MSHA), representing 55% of the ground-fall-related fatalities in U.S. underground coal mines. During the five-year period of 2015 through 2019, nine rib-fall-related fatalities increased this proportion to 82% of ground-fall-related fatalities. According to MSHA statistics, during this same time period, 89% of the rib fatalities in U.S. underground coal mines occurred in the Eastern coal basins (Appalachian and Illinois coal basins). Based on these injury statistics, more emphasis should be devoted to reducing rib fall incidents in coal mines operating in the Eastern coal basins. This can be done by developing an engineering-based design methodology that defines the appropriate level of rib support.

Research Aims

To address the above issue, this project had four research aims, as follows:

(1) develop a logical procedure for a Coal Pillar Rib Rating (CPRR);

(2) improve the understanding of coal rib deformation and rib-support interaction;

(3) identify critical parameters affecting rib stability; and

(4) develop and test the design methodology for rib control.

In the first year of this project, researchers created a CPRR rating system that was used to assess the inherent structural competency of coal ribs. The research developed data collection protocols for visited mine sites and a systematic procedure for computing the CPRR. Compressive strength testing was conducted for rib units (coal and rock). By the end of the project, this rating system for given overburden depths was then used to define the required support to be installed to prevent accidents caused by rib falls. These support designs are based on engineering stress models that have been evaluated and verified at several underground mines through monitoring.

In the second and third years of this project, NIOSH researchers monitored coal rib and support response at study sites, conducted compressive strength testing for rib units, calibrated a previously developed NIOSH rib model using the field monitoring data, verified the calibrated rib model using published rib monitoring case studies, and presented papers about the project findings at international conferences.

In the fourth and final year of the project, researchers conducted parametric studies of factors affecting rib stability, established statistical relationships between the critical parameters and rib stability factors, developed a tool to design and analyze rib stability, and published the project findings in a peer-reviewed journal.

Coal Pillar Rib Rating and Factor of Safety Calculations for Solid Coal Ribs

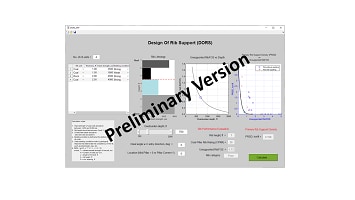

Through underground coal mine investigations, three main rib categories were observed: (1) solid coal ribs with or without thin partings of thicknesses under 2 in., (2) coal ribs with in-seam thick partings (greater than 6 in.), and (3) coal ribs with a roof brow. By applying the CPRR technique to in-mine observations, NIOSH researchers identified the geotechnical factors that influence the structural competency of coal pillar ribs and the mechanisms of rib spalling. A user-friendly application called Design of Rib Support (DORS) was developed (see figure) to: (1) evaluate the rib performance by calculating the CPRR, Rib Factor Of Safety (RibFOS), and Rib category, (2) calculate the Primary Rib Support Density (PRSD) for unsupported coal ribs.

Anticipated Outcome

The ultimate goal of this project research is to reverse the current trend of rib fall incidents in Eastern coal basins. The achieved minimum rib support standards could be adopted by enforcement agencies that approve rib control plans.

Selected References

1. Mohamed, K., Murphy, M., Lawson, H., and Klemetti, T, 2015a. Analysis of the current rib support practices and techniques in U.S. coal mines. International Journal of Mining Science and Technology, Volume 26, Issue 1, January 2016, Pages 77-87.

2. Mohamed, K.M., Tulu, I.B., and Klemetti, T., 2015b. Numerical Simulation of Deformation and Failure Process of Coal-Mass. Proceedings of the 49th US Rock Mechanics/Geomechanics Symposium, Alexandria, VA, American Rock Mechanics Association.

3. Mohamed, K., Tulu, B., Murphy, M., 2016. Numerical model calibration for simulating coal ribs. Proceedings of the 35th International Conference on Ground Control in Mining, Morgantown, WV, University of West Virginia, pp. 289–298.

4. Sears, M.M, Rusnak, J., Van Dyke, M., Rashed G., Mohamed, K., and Sloan, M., 2017. Coal Rib Response during Bench Mining: A Case Study. Proceedings of the 36th International Conference on Ground Control in Mining, Morgantown, WV, University of West Virginia, pp. 67–75.

5. Zhang, P., Mohamed, K.M., Tulu, I.B., and Trackemas, J., 2017. Coal Rib Failure and Support in Longwall Gate Entries. Proceedings of the 51st US Rock Mechanics/Geomechanics Symposium, Alexandria, VA: American Rock Mechanics Association.

6. Mohamed, K., Rashed G., Sears, M., Rusnak, J., and Van Dyke, M., 2018. Calibration of a coal-mass model using an in situ coal pillar strength study. SME Annual Meeting, Feb. 25–28, 2018, Minneapolis, MN.

7. Mohamed, K., Cheng, Z, and Rashed G., 2019. Coal Rib Stability Based on the Strength Reduction of the Coal Mass Model. Proceedings of the 53rd US Rock Mechanics/Geomechanics Symposium, New York, NY: American Rock Mechanics Association.

8. Mohamed, K., Van Dyke, M., Rashed G., Sears, M.M, and Kimutis, R., 2020. Preliminary Rib Support Requirements for Solid Coal Ribs Using A Coal Pillar Rib Rating. Proceedings of the 39th International Conference on Ground Control in Mining, SME, eBook, ISBN: 9780873354806.

9. Rashed G., Mohamed, K., and Kimutis, R., 2020. A Coal Rib Monitoring Study in a Room-and-Pillar Retreat Mine. Proceedings of the 39th International Conference on Ground Control in Mining, SME, eBook, ISBN: 9780873354806.

- Current trends in Reducing Ground Fall Accidents in US Coal Mines

- Current Trends in Reducing Ground Fall Accidents in US Coal Mines

- Dynamic Failure in Deep Coal: Recent Trends and a Path Forward

- Ground Control Overview

- Horizontal Stress

- Rib Falls: A Major Ground Control Issue

- Rib Stability: Practical Considerations to Optimize Rib Design

- Rock Falls

- Roof and Rib Fall Incident Trends: a 10-Year Profile

- Roof and Rib Hazard Assessment for Underground Stone Mines