Parked Forklift Crushes Operator Against Semi-Trailer

Oregon Case Report: 04OR004

Summary

On February 10, 2004, a 42-year-old forklift operator was crushed between the forklift he had been operating and a semi-trailer he was helping to load. Assisting the truck driver to tie down the load, the operator backed the forklift to the opposite side of the trailer, put the automatic transmission into neutral, engaged the parking brake, and jumped out to take the strap thrown across the load by the truck driver. The forklift’s engine was left running. While the operator was facing the trailer and busy with the strap, the forklift engaged in reverse and backed into him, crushing him against the trailer with enough force to make the trailer shudder. The truck driver looked under the trailer and saw the victim’s legs dangling in the air. He ran to engage the gearshift on the forklift into forward to release the victim. Efforts to revive the victim were unsuccessful, and he was pronounced dead at the scene.

|

|

Twin of forklift that backed into and crushed the operator after he jumped out to help load a truck.

|

Recommendations

- Before exiting any powered industrial truck, even briefly, completely shut down power, place controls in neutral and apply parking brake.

- Employers should provide ongoing evaluation and feedback for operators of mobile machinery to ensure that operator proficiency and safe work practices are maintained.

- Maintain the machine in safe operating condition.

- Employees should be encouraged to report concerns related to the safe operation and maintenance of mobile machinery.

Introduction

On February 10, 2004, a 42-year-old Hispanic forklift operator was crushed between the forklift he had been operating and a semi-trailer he was helping to load. The incident occurred at about 2 p.m. OR FACE received notification of the incident on February 11. An onsite visit and interview with the employer was conducted on February 12. Copies of the sheriff and deputy medical examiner reports were obtained from the county sheriff, and the investigating deputy was interviewed. A representative of the forklift manufacturer was also interviewed, and the Operator’s and Owner’s Manual was obtained. Reports were also obtained from the state police and OR-OSHA.

The employer manufactures fuel for wood pellet stoves, fireplace logs, and products for enhancing the flavor of smoked meats. The company employs 36 employees at this location, mostly of Hispanic ethnicity.

The company’s two identical forklifts are maintained by a mechanic onsite, with on-call support from a manufacturer’s representative. Operation and maintenance training on the equipment was sponsored by the employer in 1999, and again in 2001. All employees at the facility were issued certificates on forklift operations. The training sessions were in Spanish. The employer has a written safety program and safety committee, with a suggestion box in the lunch room.

The victim worked for the employer for 8 years, and was experienced in operating the forklift. He was viewed as a leader who communicated well with management and the largely Spanish-speaking workforce. He was fluent in English.

Investigation

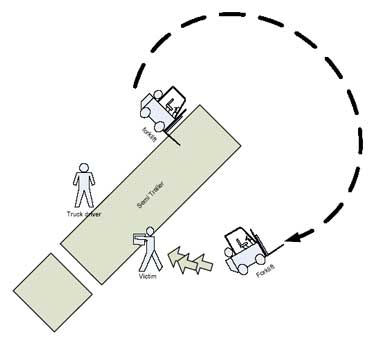

On the day of the incident, the forklift operator completed loading a curtain semi-trailer with pallets of product, and noticed the truck driver needed help with the straps to secure the load. He backed the forklift around to the opposite side of the trailer from the driver, pushed the automatic transmission into neutral, engaged the parking brake, and jumped out to fix the strap on the load.

While the operator was facing the trailer, the forklift unexpectedly engaged in reverse and backed into him, crushing him against the trailer with enough force to make the trailer shudder. The truck driver looked under the trailer and saw the operator’s legs dangling in the air. He ran to the other side, heard the operator having difficulty breathing, and hurriedly engaged the gearshift on the forklift into forward to release him. The victim fell to the ground, with extensive chest and airway injuries. Efforts to revive him were unsuccessful, and he died shortly thereafter at the scene. The truck driver was the only other worker present at the time of the incident.

The forklift was parked approximately parallel with the trailer, an estimated 4-6 feet away. The forks were on the ground, in accordance with safe practice, but the engine was left running, and the wheels were turned in the direction where the worker was standing. The mechanism by which the forklift drive engaged and moved from its parked position remains uncertain. The following points bear on the issue.

- The surface of the yard where the forklift was parked next to the semi-truck is hard-packed gravel with a 2.5% slope. Testing determined the slope was not sufficient to cause the forklift to roll without power.

- The forklift was equipped with an operational backup alarm system, but the backup alarm did not sound before the forklift struck the victim. After repeated testing and some difficulty, it was found the gearshift could be adjusted to move the machine in reverse without the alarm sounding.

- The second forklift at the company was under repair on the day of the incident, so the single forklift performed all activity, and the brakes may have overheated and failed. The truck driver was apparently able to put the machine in gear and move it forward without releasing the brake. Later inspection showed the brake system on the forklift, though poorly maintained, met safety specifications.

|

|

Victim’s position when the forklift struck him.

|

Cause of Death

Crush injuries to chest and head.

Recommendations/Discussion

Recommendation #1: Before exiting any powered industrial truck, even briefly, completely shut down power, place controls in neutral and apply parking brake.

The forklift should be secured so that it will not move when the operator is not in the driver’s seat. Operators should always: (a) place the front forks in firm contact with the ground, (b) turn the steering wheels away from the direction where work will be performed, (c) put the shift in neutral and set the parking brake, (d) shut off the engine, and (e) block wheels if parked on an incline.

Recommendation #2. Employers should provide ongoing evaluation and feedback for operators of powered industrial trucks to ensure that operator proficiency and safe work practices are maintained.

The employer supplied forklift training to workers. The manufacturer’s operation manual recommends employers follow training requirements outlined in the manual, as well as guidelines from ANSI Std. B56.1-1993 and OSHA Standard 29CFR1910.178. Employers should ensure that operator proficiency is maintained through evaluations and random checks. Training should be repeated whenever there is a noted deficiency. In addition, retraining should be performed at least every 2 years.

Recommendation #3. Maintain the machine in safe operating condition.

Although the mechanical basis of this incident is difficult to reproduce, there is some indication that the forklifts at the work site were heavily used and may have been in need of preventive maintenance or repairs. Equipment should not be used unless needed repairs are completed and the machine is in safe operating condition. Written documentation is an important component of a safety program. A standard checklist helps to identify hazards, and encourages accountability for regular inspections and a timely response to safety concerns.

Recommendation #4. Employees should be encouraged to report concerns related to the safe operation and maintenance of mobile machinery.

A work site safety committee provides an opportunity for employees to report unsafe working conditions or equipment in a cooperative, nonadversarial environment. To be effective, a safety committee needs to actively encourage employee feedback, and also evaluate its own procedures to be sure employees are contributing and feel their contributions are valuable. Accountability for both employer and employees may be improved by the safety committee promoting its activities and accomplishments, and explicitly recognizing the contribution of employee suggestions. Employee feedback should be documented and included in the minutes of the safety committee.

References

- Center for Research on Occupational and Environmental Toxicology (n.d.). Powered industrial trucks (forklifts). Online information resource: http://www.croetweb.com/links.cfm?subtopicID=373

- Nash, J. (2004). Construction safety: Best practices in training Hispanic workers. Available online: http://ehstoday.com/construction/news/ehs_imp_36851/

(Link updated 4/1/2013) - National Institute for Occupational Safety & Health (2001). Preventing injuries and deaths of workers who operate or work near forklifts [Pub 2001-109]. Available online: https://www.cdc.gov/niosh/2001-109.html

- Oregon Occupational Safety & Health Administration (2005). Safety committees for the real world: OR-OSHA’s guide to starting an effective workplace safety committee. Available online: http://www.cbs.state.or.us/external/osha/pdf/pubs/2341.pdf (Link no longer available 3/31/2009)

- Oregon Occupational Safety & Health Administration (2005). Innovative safety committees. Available online: http://www.cbs.state.or.us/external/osha/pdf/pubs/3124a.pdf (Link no longer available 3/31/2009)

- Occupational Safety and Health Administration. (n.d.). Powered industrial trucks. Online information resource: https://www.osha.gov/SLTC/poweredindustrialtrucks/index.html

Oregon FACE Program

The Center for Research on Occupational and Environmental Toxicology at Oregon Health & Science University performs Fatality Assessment and Control Evaluation (FACE) investigations through a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR). The goal of these evaluations is to prevent fatal work injuries in the future by studying the working environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in fatal injury, and the role of management in controlling how these factors interact.

To contact Oregon State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Oregon FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.