Steel Erector Falls From Scissors Lift

April 25, 2001

Nebraska FACE Investigation 00NE050

SUMMARY:

A 61 year old steel erector was killed when he fell approximately 25 feet from a scissors lift. The victim was installing bolts on overhead beams at a new warehouse construction site. For unknown reasons, the lift left level ground and rolled into a twelve inch deep ditch, causing it to topple over forwards, ejecting the victim. He was airlifted to a local hospital where he was pronounced dead.

The Nebraska Department of Labor Investigator concluded that to prevent future similar occurrences:

- Employees should obey all written safety requirements of the piece of equipment they are operating.

- Employers should verify successful training on the particular type of equipment the employees will be utilizing.

- Employers should provide suitable equipment to safely perform the assigned tasks.

PROGRAM OBJECTIVE:

The goal of the Fatality Assessment and Control Evaluation (FACE) workplace investigation is to prevent work-related deaths or injuries in the future by a study of the working environment, the worker, the task the worker was performing, the tools the worker was using, and the role of management in controlling how these factors interact.

This report is generated and distributed solely for the purpose of providing current, relevant education to employers, their employees and the community on methods to prevent occupational fatalities and injuries.

INTRODUCTION:

On November 30, 2000 at approximately 8:00 a.m., a 61 year old steel erector was killed when the scissors lift he was operating toppled over forwards, ejecting him. The Nebraska Department of Labor was notified of the fatality the same day by OSHA and the local news media. The Nebraska FACE Manager and Investigator met with the investigating OSHA Compliance Officer on December 14, 2000 and February 22, 2001 to review incident site tapes and to discuss particular facts of the mishap. The Investigator also met with company officials on February 14, 2001. County and local law enforcement reports concerning this incident were also reviewed.

The employer is a structural steel erection company that works primarily on commercial buildings. The have been in business for approximately two years and employed seven at the time of the accident. They had been at this job site for approximately one week. The company does have a written safety program. One of the owners serves as the company’s safety manager. They have no previous history of fatalities.

INVESTIGATION:

The victim was a 61 year old male steel erector. He had been employed in the structural steel erection occupation for many years. He had been employed by another company for the past four years, but was recently let go. While employed by that company he had been tested and certified in all types of scissors lifts less than a year before. Upon hiring the victim was asked if he knew how to operate scissors lifts, and he said that he was certified by his previous company. The company did not call to verify that information. When the previous company was contacted by the investigator, they did confirm that training was given, and that the victim had successfully passed and subsequently was certified in all types of scissors lifts. The company safety director stated that prior to the start of work on the victim’s first day, he was briefed to use the accident lift only until he reached the area of the building where there was a small ditch, which should take two days. At that point they would use a lift with a personnel basket for safer and easier access. The ditch measured approximately eighteen inches deep by several feet across. The footings for the building were directly in the middle of the ditch. The JLG lift was rented from a local company and was relatively new with only 500 hours on the operating meter. The motor is located in the “back” end, and the scissors mechanism is set towards the “front” of the machine. The rear wheels are direct drive. The control box is “free standing”, which allows the operator to control the lift from any position on the working platform. The control box has an emergency stop button (red, mushroom shaped). This lift also had an extension working platform that extended several feet over the end of the unit. For the first two days the victim used the lift to install overhead beam bolts with no known problems. He had been observed by coworkers numerous times moving the scissors lift, always in the “down” position. On the third day, the day of the incident, the victim started working at the mishap site at 7:30 a.m. At approximately 8:00 a.m., the victim was ready to start work near the ditch. There was no other piece of equipment available on site to allow the victim to continue performing his assigned task, except for the accident lift. The victim turned the lift towards the structure and raised it to a working level, approximately 24 feet. The extension working platform was over the ditch, facing the structure. The victim was standing on the extension platform while inching it forward to place himself under the new work area. (The control box was attached to the safety railing at the front of the extension platform after the fall) The front wheels slipped over the edge of the ditch, causing the lift to “teeter totter” on the front wheels. The victim attempted to stop the forward motion by depressing the emergency STOP button, which locked up the rear tires, which were already either off the ground or barely touching. The lift went over forward, ejecting the victim. Although all the company’s employees were on site, no one actually saw the lift topple. The victim was administered first aid by coworkers until emergency personnel arrived. He was air lifted to a local hospital where he was pronounced dead.

CAUSE OF DEATH:

Ruptured left pulmonary artery with resulting cardiac tamponade.

RECOMMENDATIONS/DISCUSSION:

Recommendation #1: Employees should be made aware of and obey all written safe work practices for the particular piece of equipment they are operating.

The company was in possession of three different safety manuals for scissors lifts. Each states that this particular lift will not be operated over uneven ground or around areas where there is debris scattered about. The OSHA standard says that mobile scaffolds will not be moved while in the elevated position if the ground surface is within 3 degrees of level, and not free of pits, holes and obstructions. (Reference 29 CFR 1926.21b(2))

Recommendation #2: Employers should verify employees are currently qualified to operate their assigned equipment.

When first hired, the victim stated he was qualified on the new company’s particular scissors lift. The employer did not contact the victim’s previous company to verify this information, nor did they provide the victim any safety training on their lift. (Reference 29 CFR 1926.20b(4) & 1926.21b(2))

Recommendation #3: Employers should ensure suitable equipment is available which allows the employees to safely perform their assigned tasks.

The accident lift was suitable for the task at hand, until the area of the ditch was reached. The victim had been told the company would provide a different lifting device that would safely reach the required elevation. That lifting device had not been brought to the job site when the victim was ready to place bolts over the ditch area. (Reference 29 CFR 1926.20a(1))

ATTACHMENTS:

|

|

|

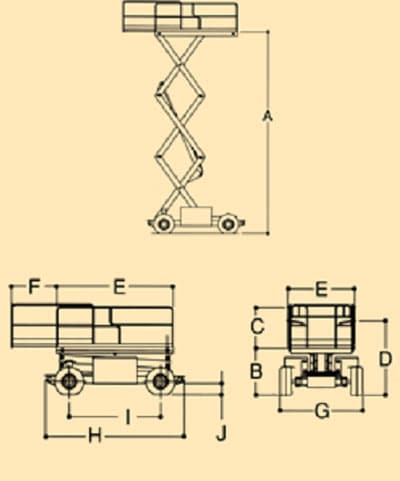

Examples of scissors type lift with manually extended platform.

|

|

|

|

|

Figure #1. Drawing of lift with dimensions, etc.

|

|

| A. Platform height (elevated) = 26 ft. | I. Wheelbase = 6 ft. 6 in. |

| B. Platform height (lowered) = 4 ft. 1.5 in. | J. Ground clearence = 8 in. |

| C. Platform railing height = 3 ft. 7.5 in. | Platform capacity = 1,250 lbs. |

| D. Overall height = 7 ft. 9.5 in. | Extension capacity = 300 lbs. |

| E. Platform size = 65 x 102 in. | Max drive height = full height |

| F. Platform extension = 4 ft. | Drive speed lowered = 3.5 mph |

| G. Overall width = 5 ft. 9 in. | Drive speed elevated = 0.4 mph |

| H. Overall Length = 8 ft. 9 in. |

REFERENCES:

OSHA Part 1926 Code of Federal Regulations for Construction Standards

To contact Nebraska State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.