Construction Zone Worker Hit By Gravel Truck in Nebraska

January 31, 2001

Nebraska FACE Investigation 00NE034

SUMMARY:

A 57-year-old construction superintendent was killed when he was struck by a gravel truck. The victim was filling concrete expansion cracks with tar in the southbound lane of two-lane concrete state highway. A gravel truck approaching from the north (same lane) came upon the construction zone, saw the flag person ahead and hit his brakes hard, but was unable to stop. The truck initially skidded straight towards the victim, but at the last few seconds started to jackknife. The victim attempted to escape by running across the northbound lane, but was caught between the gravel truck and the tar equipment. The victim was pronounced dead at the scene.

The Nebraska Department of Labor Investigator concluded that to prevent future similar occurrences:

- Employers should ensure that adequate warning signs are placed prior to the construction site.

- When working in the middle of a highway while allowing traffic on both sides, flaggers should be used at both ends of the construction zone.

- Employers should consider lowering the work site speed limit below that of the regular construction zone.

- Employers may consider, where the work site is constantly changing, to have a vehicle following the workers with directional arrows, flashing lights and/or beacons to alert oncoming traffic and serve as a personnel barrier.

PROGRAM OBJECTIVE:

The goal of the Fatality Assessment and Control Evaluation (FACE) workplace investigation is to prevent work-related deaths or injuries in the future by a study of the working environment, the worker, the task the worker was performing, the tools the worker was using, and the role of management in controlling how these factors interact.

This report is generated and distributed solely for the purpose of providing current, relevant education to employers, their employees and the community on methods to prevent occupational fatalities and injuries.

INTRODUCTION:

On October 19, 2000 at approximately 12:35 p.m., a 57-year-old construction superintendent was killed when he was struck by a gravel truck. The Nebraska Department of Labor was notified of the fatality on October 19, 2000 by OSHA and the local news media. The Nebraska FACE Manager and Investigator met with an OSHA Compliance Officer on December 14, 2000 to review incident site tapes and to discuss particular facts of the mishap. The FACE Manager and Investigator also reviewed County and State law enforcement reports concerning this incident.

The employer is a construction company that works primarily on roadways. They have been in business for over 10 years. They had been working on this highway section for several months, and were in the process of finishing the project by sealing the expansion joints/cracks with tar. The company does not employ a full time safety manager. They have no previous history of fatalities.

INVESTIGATION:

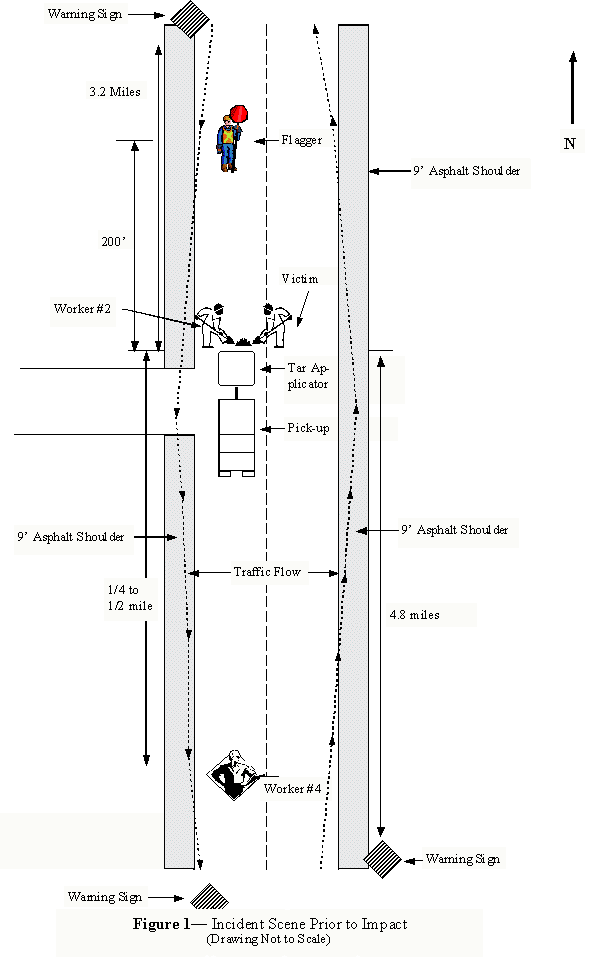

On the day of the incident the victim started working at the mishap site at approximately 7:30 a.m. The incident happened at approximately 12:35 p.m. The victim was a construction superintendent. On this day he was operating a Crafco tar applicator (orange in color), used to fill expansion cracks in the concrete highway with hot tar. There are no warning lights or signs on the tar machine. The tar machine is mounted on a trailer which was towed by a 1989 Ford F250 pickup truck (tan in color). The pickup truck had a single yellow strobe light on the roof and the rear 4-way flashers were operating. The highway is a two-lane north-south newly milled concrete road with 9-foot wide asphalt shoulders. The roadway surface was dry. Weather was not a factor in this mishap. On each end of the construction zone there was a single orange/black rectangular shaped sign stating ROAD CONSTRUCTION AHEAD NEXT 7 MILES, followed by a 50 MPH black/white speed limit sign with an orange/black rectangular FINES DOUBLE marking, then an orange/black rectangular sign stating NO PASSING – LANES NOT MARKED. The signs for the southbound lane are approximately 3.2 miles from the site, and the northbound lane signs are approximately 4.8 miles from the accident site. There were no cones, barrels or markings indicating a flagger or lane closures on either end of the work site. There were numerous construction barrels not being used along the entire 7-mile construction zone. The flagger carried the standard 18″ STOP/SLOW sign. She was wearing an orange hat and vest.

There were 4 workers from this company involved with filling the cracks. Worker #1 (victim) and worker #2 were operating the tar applicator, which was parked in the southbound lane attached to the pickup. Worker #3 (flag person) was approximately 200 feet north of the mishap site, standing in the middle of the southbound lane. Worker #4 was approximately one quarter to one half mile south of the accident site also in the southbound lane using compressed air to remove any foreign debris that may have accumulated in the cracks. Southbound traffic was being diverted by the flagger to the southbound (west) shoulder. Northbound traffic was uncontrolled. The tar applicator and pickup truck were also in the southbound lane. This created an “island effect” for the work crew. The gravel truck driven by Operator #1 is a 1995 International Model 920, which was towing a “pup” 1979 Fruehauf trailer. The truck was in good mechanical condition.

As the gravel truck approached the work site at approximately 50 mph (posted limit), Operator #1 saw the flagger in the middle of the southbound lane just as she turned the sign from STOP to SLOW. He applied his brakes hard and started to skid straight towards the work site. The flagger realized the truck was not going to stop in time and yelled a warning to the other workers. She ran to the west, across the shoulder into the ditch and escaped. The victim and worker #2 had just finished filling the center crack and had shut the tar wand off, preparing to move south several feet to the next crack. The victim and worker #2 heard the verbal warning and attempted escape in different directions. Worker #2 also ran west into the ditch and escaped. The victim attempted to run to the east across the northbound lane. The truck continued in a straight skid until the last few seconds when it started to jackknife, turning counterclockwise and angling towards the opposite lane. The victim was caught between the outside dual passenger rear axle/tire and the tar applicator machine, knocking him onto the east roadway shoulder. The truck came to rest facing due east with the rear wheels on the shoulder and the front wheels off the roadway. The “pup” trailer was facing southeast. The pickup truck and tar applicator were shoved ahead and came to rest facing east and southwest respectively. The tongue on the applicator was broken by the impact and the pickup and applicator were not attached at the hitch. Rescue personnel were called by a motorist and arrived within minutes. The victim was pronounced dead at the scene. The truck operator was issued a citation for Motor Vehicle Homicide.

CAUSE OF DEATH:

The cause of death as stated on the death certificate was multiple head and internal injuries as the result of a motor vehicle — pedestrian accident.

RECOMMENDATIONS/DISCUSSION:

Recommendation #1: Employers should ensure that signs warning of “FLAGGER AHEAD” are prominently placed on the road shoulder well in advance of the actual work site.

There were no signs in the Advance Warning Area on either lane indicating there was a flagger ahead. In the Advance Warning Area drivers are informed of what to expect. The advance warning may vary from a single sign and/or flashing lights on a vehicle to a series of signs in advance of the temporary traffic control zone transition area. These may be placed 500 feet to ½ mile or more before the temporary traffic control zone. Rural roadways are characterized by higher speeds. Spacing for the placement of warning signs is substantially longer — from 8 to 12 times the speed (mph) in feet. Two or more advance warning signs are normally used in these conditions, extending 1,500 feet or more in open highway conditions. [Ref: Part VI, Manual on Uniform Traffic Control Devices, February 19, 1998, Revision 4A, pg. 46, para. 6F-1b(6)&(11)]

Recommendation #2: When allowing traffic to continue on both sides of the work site, employers should use flaggers at both ends of the work zone to ensure positive speed control of both lanes of traffic.

The use of only one flagger allowed northbound traffic to operate at full speed (posted 50 mph) with no advance warning of the work site, except for the initial warning signs 4.8 miles to the south. There were no construction vehicles or equipment with strobes, etc. near the worker to the south, exposing him to danger from both sides of the work zone. [Ref: Part VI, Manual on Uniform Traffic Control Devices, February 19, 1998, Revision 4A, pg. 26, para 6C-5a & pg. 34, para. 6E-6]

Recommendation #3: Employers should consider reducing the posted traffic speed limit through highway construction and work zones.

The posted speed limit was 50 mph for the entire 7-mile construction zone. A lower speed limit, indicated by prior warning signs/lights would allow vehicle operators to slow down prior to entering the work zone. At 50 mph, it was impossible for a vehicle of this size to stop in the distance between the flagger and the victim. [Ref: Part VI, Manual on Uniform Traffic Control Devices, February 19, 1998, Revision 4A, pg. 31, para. 6D-2]

Recommendation #4: Employers should consider, for operations involving constant work site changes, that a vehicle equipped with flashing arrows, changeable message signs, and/or flashers and a truck mounted attenuator (TMA) follow the mobile work site.

This vehicle must be located properly in advance of the workers and/or equipment they are protecting. However, these vehicles themselves may cause injuries to occupants of the errant vehicles if they are not equipped with truck-mounted attenuators. TMAs capable of absorbing the impact of errant vehicles can be attached to the rear of these protective vehicles to reduce the severity of rear-end crashes. The protective truck must be positioned a sufficient distance in front of the workers or equipment being protected to allow for appropriate vehicle roll-ahead, but not so far that errant vehicles will travel around the vehicle and strike the workers/equipment. The attenuator should be in the full down-and-locked position. When stationary, the truck’s parking brake should be set and the front wheels turned away from the work site. [Ref: Part VI, Manual on Uniform Traffic Control Devices, February 19, 1998, Revision 4A, pg. 75, para. 6F-8a(2) & pg. 96, para. 6H-2c(2)]

REFERENCES:

Part VI, Manual on Uniform Traffic Control Devices, February 19, 1998, Revision 4A.

To contact Nebraska State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.