Farmer Crushed Under Bucket of a Skid-Steer Loader

Iowa Case Report: 03IA054

Report Date: March 17, 2004

Summary

During the fall of 2003, a 46-year-old Iowa farmer was killed while operating a skid-steer loader on his farm. He had purchased the loader recently, and was using it to remove corn fines from a grain handling area into an adjacent field. While doing this, he apparently backed the loader into a 1,000 gallon (3800 L) propane tank and knocked it off its concrete block foundation. The tank tipped over sideways towards a grain dryer, which was running, and the valve on top of the tank hit a post and started venting propane. The LP tank was nearly empty and was to be filled that morning. The farmer positioned the skid-steer loader near one end of the tank, with the bucket raised and the engine running. He apparently leaned or stepped out of the loader, and accidentally activated the foot pedal controlling the height of the loader lift arms. As the bucket came down, he was pinned under the bucket against the loader frame on the left front side.

|

| Photo 1 – Side view of area showing skid-steer loader in the position it was found, overhead grain auger, propane tank (liquid petroleum, LP) overturned against a pole for the dryer, and a close-up of the bent propane valve. |

The farmer was working alone and the exact circumstances of this incident are unknown. It is likely he noticed the propane leak from the sound or the odor, and was in a hurry to close the leaking valve. The position of the loader suggests he may have been planning to get a chain and raise the tank back up with the loader bucket. This 1980 model loader showed significant wear from previous use. The foot pedals on both sides had worn linkages, and metal risers had been added to the heel portions of the pedals to allow more normal use of the pedals. These risers reduced room and added clutter in the tight space for the pedals, however, it’s not clear whether they contributed to this incident. Some time after the incident, a propane delivery truck arrived to fill the empty tank. The driver discovered the victim and called 911 for help, but by this time the farmer was already dead at the scene. The deliveryman turned off the grain dryer and called a relative. The victim was a life-long farmer and had used many types of farm machinery, however, he had purchased this used skid-steer loader only three weeks prior to his death and may not have been very familiar with its operation.

Recommendations based on our investigation are as follows:

- Manufacturers should provide reliable safety features to prevent operators from being crushed under skid-steer loader buckets.

- Skid-steer loader operators should not exit or enter the loader under a raised bucket.

- Owners of skid-steer loaders should not modify machine controls.

Introduction

In September 2003, a 46-year-old hog farmer was killed while using a skid-steer loader on his farm. The Iowa FACE program was notified of this incident a few days later by a newspaper article, and began an investigation. Information and photographs were gathered from the local sheriff and the medical examiner’s office, and a site visit was scheduled to view and photograph the loader at a local machinery dealer. Two FACE investigators examined the machine and later talked with the victim’s father, who also worked at the farm.

The victim was a life-long farmer who currently farmed over 800 acres in corn, soybeans, and wheat. He managed an 8,000 head hog operation and a custom trucking business as well. He was normally assisted by his oldest son and his father, who also drove truck for him. The victim was working alone at the time of his death. There were no safety programs, nor written policies in place at this farm. The victim had experience with skid-steer loaders, but had purchased this older used machine only three weeks prior to the incident, and did not have much experience operating it.

Investigation

The fatality occurred during harvest at a farm grain handling site in Iowa. The farmer was moving corn from the grain dryer to a bin with an overhead auger, as seen in Photo 1. A pile of corn fines accumulated on the ground beneath the auger, and the farmer was using the skid-steer loader to move the fines out of the way to a location in an adjacent field. The grain dryer was in operation, receiving propane from the adjacent tank. The farmer was working alone, operating an older skid-steer loader, which he had recently purchased. The loader was a 1980 Bobcat, model 631. It had a seatbelt but no electrical or mechanical safety interlocks that would control the hydraulics if the operator was not sitting in the seat. The seatbelt was not used at the time of the incident.

|

| Photo 2 – Back view of the area showing skid-steer loader, overturned tank, the grain dryer, and the pile of corn fines. |

It had rained the night before, so it was possible for Sheriff’s investigators to determine where the loader had been operating that morning by observing fresh tracks in the dirt. It appeared that while loading up fines with the bucket, the farmer accidentally backed into one end of the propane tank, knocking it off its concrete foundation. Fresh marks in the paint on the tank and tracks in the dirt suggest the farmer was trying to re-position the tank after it had tipped over on its side, toward the grain dryer. The top-mounted valve (see Photo 1) had struck a dryer pole and was venting propane. The farmer moved the loader to the opposite end of the tank and raised the bucket, possibly preparing to reposition the tank with a chain. Considering the noise level from the dryer and the skid-steer loader, it’s not clear whether he heard the sound of the leaking propane. However, it is likely he noticed the odor of the leaking gas, and knew it was an explosion hazard. Either the grain dryer, which was running, or the skid-steer loader itself could ignite the propane, and the farmer was likely aware of this and had great urgency to correct the situation.

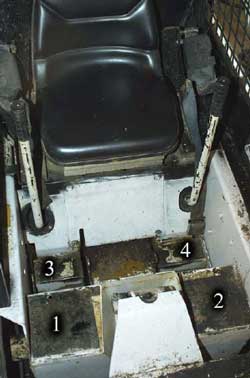

The propane tank was nearly empty and relatively light to move with the loader. The farmer had positioned the loader near the far end of the tank, and had raised the bucket lift arms. The position of the loader suggests he may have planned to get a chain, attach it to the top brackets of the tank, and lift it back onto its footings. However, the exact events are unknown, as the victim was working alone at the time. Apparently, he leaned or stepped out of the machine, and while doing so, the left foot pedal controlling the lift arm height was activated. As the bucket came down, it pinned him between the bucket and the loader frame on the left side of the machine. Pushing forward on the left foot pedal (see Photo 3) will immediately lower the lift arms. Pushing forward on the right pedal will tilt the bucket down. Photo 1 shows the position of the loader when it was found with the lift arms fully lowered and the bucket tilted all the way down. The bucket could have been in the tilted position before the incident, or it could have been tilted at the same time as the lift arms were lowered.

This 1980 model skid-steer loader showed wear from previous use. The foot pedal linkages were worn and metal risers had been added to the heel portions of the pedals (see Photo 3). The riser on the left pedal was welded, and the raiser on the right pedal was fitted to slots in the pedal. These risers allowed a more normal heel position when raising the lift arms and tilting the bucket up, but they restricted the already tight space in the foot wells, and added points where the operator’s feet could get caught. However, it is unknown whether these risers contributed to this fatality.

The propane deliveryman arrived some time after the incident and found the victim crushed under the loader bucket, with the machine still running. He phoned the victim’s father who lived nearby and shut off the grain dryer when he noticed there was a leak. The victim was dead at the scene when emergency crews arrived.

|

| Photo 3- View of left foot pedal, showing angle iron welded to the heel portion of the pedal. |

Cause of Death

The cause of death as taken from the Medical Examiner’s report was, “internal bleeding in chest and abdomen due to crush injury”

Recommendations/Discussion

Recommendation #1 Manufacturers should provide reliable safety features to prevent operators from being crushed under skid-steer loader buckets.

Discussion: Many skid-steer loader fatalities have occurred with machines that lack modern safety features. The machine in this incident was manufactured in 1980, and did not have safety interlocks. Newer skid-steer loaders incorporate electrical and/or mechanical interlocks which will lock the loader hydraulics in place, protecting operators who are not properly seated in the operator station. The manufacturer in this case introduced a drop-down seat bar in 1981. This secondary restraint system, in addition to the seat belt, was not offered for 1980 and earlier models. Interlocks activated by safety bars, seatbelts, or seat pressure can be effective in preventing similar incidents, but they can also be bypassed or disabled by operators. Manufacturers should be encouraged to develop interlocking mechanisms that are easy to use, and difficult to bypass. This manufacturer has recently developed a new magnetic sensor connected to the seat bar, which may improve safety. Older machines that lack good safety features are not easy to retrofit, and recycling the machine may be the only feasible and safe alternative as these machines approach the end of their usable life-span.

Recommendation #2 Skid-steer loader operators should not exit or enter the loader under a raised bucket.

Discussion: The victim in this case was aware of this hazard and had warned his teenage son just a few days earlier to never get out of the loader with the bucket raised. The emergency situation caused by the leaking propane tank may have caught him off guard. He may have reacted instinctively trying to avoid a potentially catastrophic propane explosion. He had purchased this loader only three weeks before, and did not have much experience with it. Entering and exiting a skid-steer loader is somewhat cumbersome, as the operator station is small, and the bucket, frame elements, and controls may be in the way. This machine had some areas provided with slip resistant material to step on while entering and exiting the machine (see Photo 4). The space in the foot wells around the pedals was small and in an emergency situation, it would be possible to step on the control pedals and activate the loader hydraulics. Entering and exiting a skid-steer loader when the bucket is up is extremely dangerous and should be avoided at all times. The only exception is when properly designed mechanical lift arm stops are engaged, which will not allow the bucket to come down even if the hydraulics are activated.

|

| Photo 4– Front view of operator compartment showing hand controls and four areas for the operator to step on. |

Recommendation #3 Owners of skid-steer loaders should not modify machine controls.

Discussion: A previous owner of this machine had added risers to the heel portion of the foot pedals. The pedal linkages were worn, and needed adjustment or repair. It appears the heel position for raising the lift arms and tilting the bucket up had become awkward, and to correct this, the quickest solution for the previous owner was to add more height to the pedals with metal risers. One of them was welded, and the other was fitted between the slots of the pedal. These modifications reduced room in the already tight space in the foot wells, creating more clutter and points where the feet could get caught and accidentally activate the hydraulic controls. It’s not clear whether these modifications were a factor in this incident, however, they could compromise safe operation of the machine.

Iowa FACE Program

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds state based programs in Alaska, California, Iowa, Kentucky, Massachusetts, Michigan, Minnesota, Nebraska, New Jersey, New York, Oklahoma, Oregon, Washington, West Virginia, and Wisconsin.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct in depth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our web site listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Risto Rautiainen, PhD, Co-Investigator, Martin L. Jones, PhD, CIH, CSP, Co- Investigator, and John Kraemer, PA. From the Office of The State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.