Mining Topic: Ergonomics and MSD Prevention

What is the health and safety problem?

Ergonomics is the science of designing tasks, equipment, tools, and work environments to accommodate the capabilities and limitations of the majority of the workforce. Ergonomics enhances human performance including health, safety, and productivity. Ergonomics efforts in mining aim to prevent musculoskeletal disorders by reducing exposure to awkward postures, high force exertions, and task repetition. Outdoor and underground work environments exacerbate exposure and make ergonomics efforts more challenging than in other industry sectors.

What is the extent of the problem?

According to an OMSHR study comparing 1983–1984 and 2003–2004 MSHA data, the percentage of cumulative injuries was similar (37% and 33%), but many more work days were lost due to injury in 2003–2004. Cumulative back injuries decreased by 10%, potentially due to use of assist devices, but cumulative knee injuries increased by 8%, possibly a result of kneeling/crawling in low-seam mines.

How is the NIOSH Mining program addressing this problem?

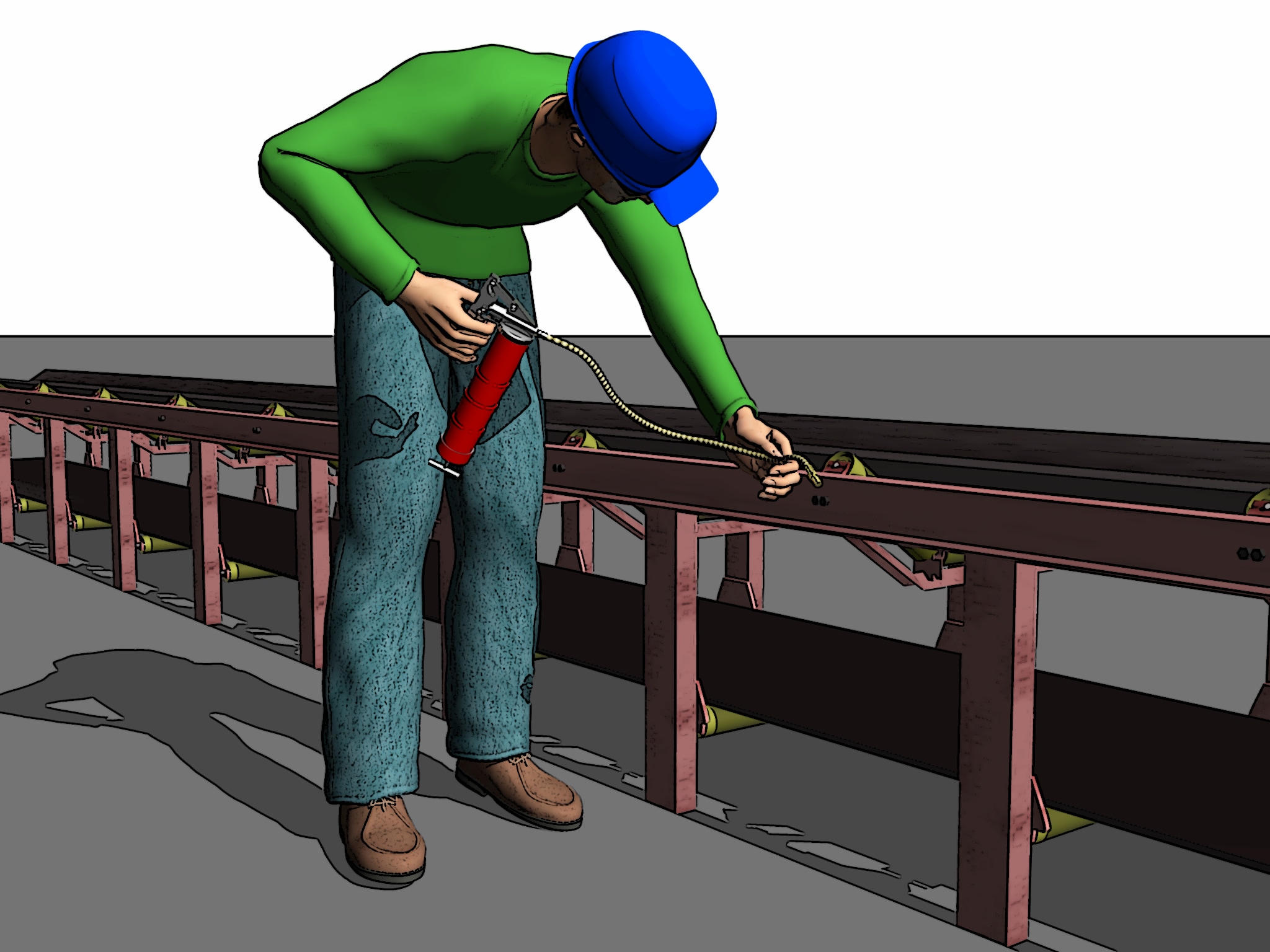

Worker bends to perform manual greasing.

Worker bends to perform manual greasing.

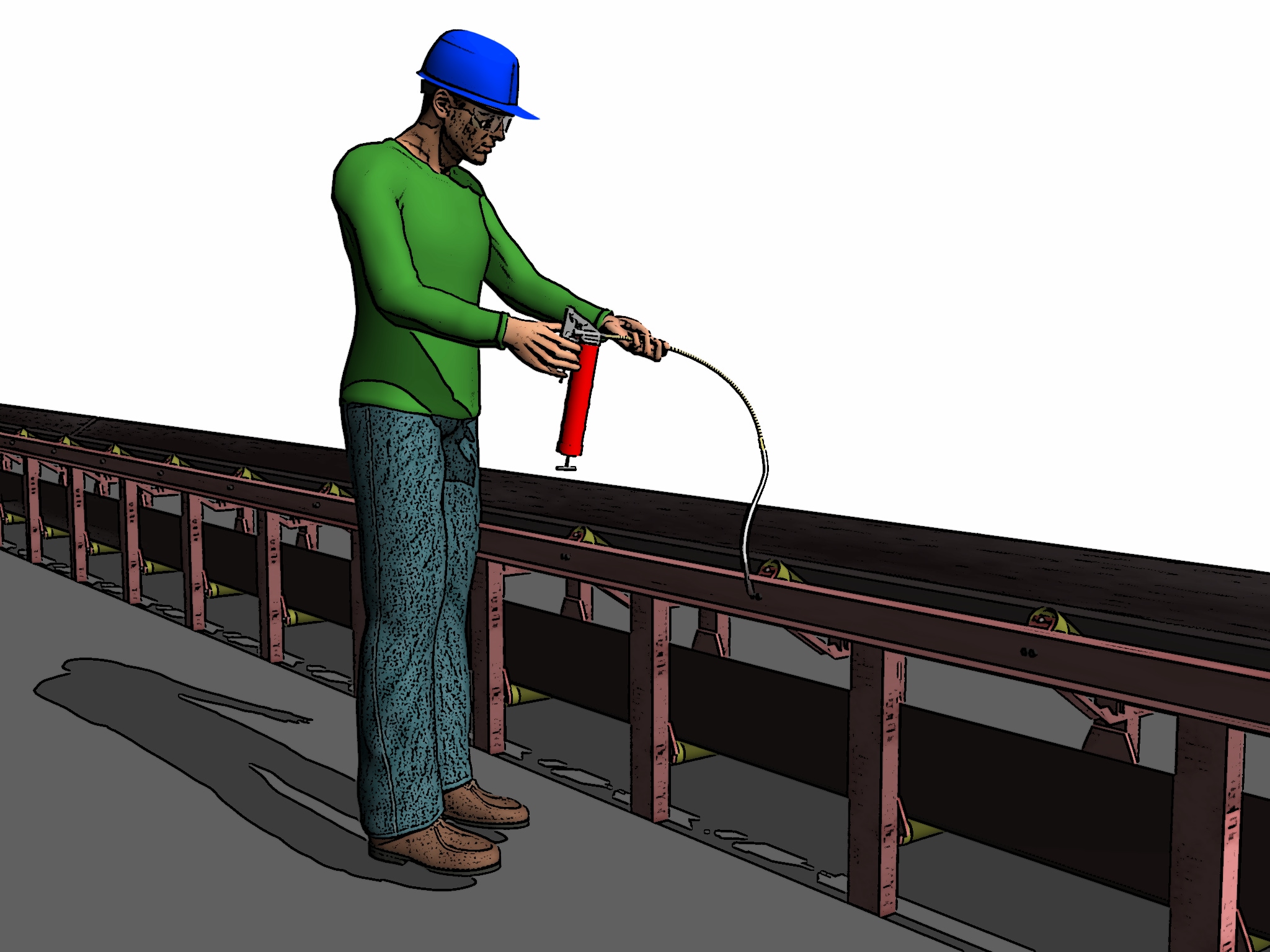

Adding an access line allows the worker to stand upright while greasing.

Adding an access line allows the worker to stand upright while greasing.

The NIOSH Mining program's recent and current research has been designed to provide tools to help mines identify risk factors and implement and audit ergonomics processes, as well as provide specific interventions to address ergonomics problems in mining. Two recent projects involved developing ergonomics audits for specific types of operations (haul truck operation, bagging operations, and maintenance and repair in processing and preparation plants) and developing a knee pad for low-seam mining environments. These projects used a mix of laboratory and field investigations to assess the problems and develop guidelines for remediating ergonomics issues. Another recent project assessed injuries sustained by mine workers when handling machine covers and guards. Two current projects are examining manual materials handling and slips, trips, and falls (STFs), which are the two leading causes of non-fatal injuries in the U.S. mining industry.

What are the significant findings?

Cumulative injuries are a major financial burden to the industry, but using NIOSH-developed tools for incorporating ergonomics in the workplace was shown to be a tremendous success, indicating that ergonomics can be used to reduce injuries and costs.

NIOSH Mining has published two ICs on ergonomics processes and participatory methods for mines: Ergonomics Process and Risk Factor Awareness. Practical Demonstrations of Ergonomics Principles was developed to provide safety trainers with several demonstrations for teaching ergonomics principles to mine workers.

With attention focused on the knee, NIOSH Mining published on preventing injury in Keeping Knees Healthy, and summarized experimental investigations of pressures and moments on the knee during different activities and while wearing different knee pads. It details stress distributions while wearing commonly-worn knee pads as well as physiological and biomechanical responses due to different postures and modes of locomotion.

The audits have been published as printable PDFs as well as an Android application for phone and tablet. The app is free and available in the Google Play store. Several recommendations that stemmed from these audits can be found in the Simple Solutions document that can be downloaded and printed.

NIOSH Mining conducted an analysis of injuries associated with machine maintenance and discovered that machine guards caused a significant number of injuries. Machine guards are designed to protect mine workers from dangerous work areas or equipment. However, the guards are often heavy pieces of solid metal that can require significant physical exertion if a mine worker has to remove the guard to perform maintenance. NIOSH Mining suggests reducing the size and weight of machine guards to reduce injuries related to machine maintenance.

Slips, trips, and falls are the second largest contributor to non-fatal injuries in the U.S. mining industry. Mine operators have indicated problem areas such as footwear and ingress/egress from mobile equipment as potential sources of STF hazards, but the exact elements of these sources that pose a risk are still largely unknown. To address these issues, NIOSH Mining is studying STF hazards at mining facilities to help identify and remediate these hazards. As part of this study, researchers examined 20 years of injury data and found that a considerable number of injuries occurred when operators were egressing from front-end loaders, most often when the operator was on the ladder or steps. Researchers recommend ensuring consistent rung heights on ladders, providing designated parking areas free of hazardous ground conditions, providing adequate lighting and handholds, using stairs instead of ladders, and to regularly inspect and maintain ingress/egress systems.

What are the next steps?

The STF project is continuing to investigate STF hazards in mining facilities. Researchers are examining the influence of metatarsal boots on ascent and descent of inclined walkways and stairs. A longitudinal study of boot wear is also in progress and aims to provide mining operations with knowledge to determine when to replace footwear. NIOSH researchers are actively working to help mining companies reduce slip, trip, and fall hazards in their work environments.

Handling materials is consistently the leading cause of non-fatal injuries in mining, resulting in nearly 70,000 days lost from work every year. To reduce manual materials handling injuries, NIOSH Mining will research safe practices and solutions for materials handling. Specifically, this project will investigate factors leading to hand and finger injuries to develop guidance and performance specifications for hand protection. Researchers will also examine the efficacy of using exoskeletons to reduce the physical demands of manual materials handling tasks at mine sites.

- A Checklist for Evaluating Cab Design of Construction Equipment

- ErgoMine - 2.1

- Ergonomic Interventions at Vulcan Materials Company

- Ergonomics Processes: Implementation Guide and Tools for the Mining Industry

- Implementation of an Ergonomics Process at a US Surface Coal Mine

- Physical Strength Assessment in Ergonomics

- Practical Demonstrations of Ergonomic Principles

- Simple Solutions for Surface Mine Workers

- Strength Testing

- Using Ergonomics To Enhance Safe Production At a Surface Coal Mine - A Case Study With Powder Crews

- Working in Unusual or Restricted Postures