Mining Contract: Real-Time Ground Movement Monitoring for Improved Safety Near Large Excavations Using Distributed Fiber Optic Sensing

| Contract # | 75D30120C09233 |

|---|---|

| Start Date | 9/1/2020 |

| Research Concept |

The current state of ground movement monitoring in active underground mines cannot provide real-time, distributed, continuous, and low-cost data acquisition over a large area within a rock mass. This problem can be addressed via advances in the application of distributed optical fiber sensing technology that has the ability to take real-time measurements; to collect data in an active mine environment and survive potential mining-related interference (blasting shock waves, vibration from mining activities, dust, water, corrosion); to measure ground movement across large and inaccessible areas without the need for multiple measurement sites; and to detect ground movement in scales that directly relate to the safety of mine personnel. |

| Topic Areas |

Contract Status & Impact

This contract is ongoing. For more information on this contract, send a request to mining@cdc.gov.

The main objective of this research is to enhance the safety of miners through real-time, distributed ground movement monitoring using a distributed optical fiber optic sensor with the goal to further the use of fiber optic-based ground movement monitoring for the mining industry, thus improving the safety of mine personnel.

Optical fiber sensors (OFS) have the ability to make continuous strain and temperature measurements in real time. OFS are immune to water damage, corrosion, and high temperatures; however, fiber optic-based ground movement monitoring remains novel to the mining industry. While there are many industrial uses for long-range distributed OFS, the relatively large spatial resolution of such systems (1m in the context of this work) limit their use as strain monitoring in situations where highly localized strains may be applied to the sensing cable. This limitation precludes the use of distributed OFS as a ground movement monitoring device in many mining scenarios, in which grouted boreholes are the likely installation method for coupling the optical fiber to the rock mass, resulting in highly localized strains along the fiber path when displacements along geologic discontinuities (faults, joints, bedding planes) are encountered.

In order to overcome this limitation, research has been conducted to modify existing fiber optic cable designs (consisting of the optical fiber, strength members, and jacket material), resulting in an innovative experimental fiber optic cable for strain monitoring in brittle installation media, such as cement/grout. Laboratory-scale displacement experiments detail the distinct advantage of the modified cable in measuring displacement magnitudes along prefabricated discontinuities in both shear and tension. In these experiments, calibration data for the novel sensor was collected such that discontinuity displacement magnitudes could be estimated from measured optical fiber signals. Optimization of the OFS prototype resulted in a sensor design that is easily installed by a small crew of miners using industry standard procedures.

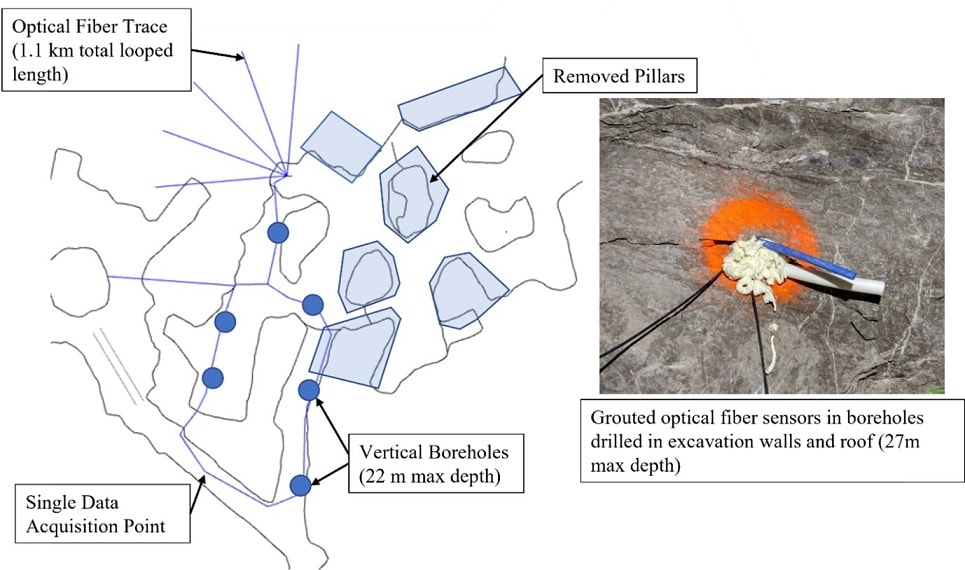

A large-scale deployment of the OFS was conducted at an active underground room-and-pillar mine with an average depth of 275 m. A total of 1.1km of fiber optic cable was installed within 12 grouted boreholes (maximum depth of 27 m) located around a pillar removal stope (see Figure 1). Continuous ground movement monitoring was conducted through the removal of six large pillars in close proximity to the installed sensors. Promising strain measurements were collected from the installed sensors: Firstly, strains associated with the curing of the cement directly after installation provided confidence in the sensors’ ability to monitor strain continuously; secondly, strain measurements from boreholes closest to the removed pillars indicated that minor ground movements have been detected.

Based on the above results, the research efforts have more recently focused on using measurements from the OFS to calibrate a numerical model of the mining section. Observations and measurements of stress and strains are often used to calibrate numerical models so that they can be used to investigate alternative mine designs to minimize risk to mine personnel and equipment. Results to date show the value of using OFS to collect strain measurements over a broad area in a mine to assess geotechnical stability of the stoping area and access points for ore removal. Moreover, the results show the value of using OFS measurements in calibrating numerical models that are used to explore adequacy of design for changing conditions or alternative mine layout designs for future excavations.

Figure 1 Left: the room-and-pillar mining area with installed optical fiber sensors in grouted boreholes. Right: Closeup of measurement borehole collar with grouted optical fiber sensors.