Mining Contract: Design of an Optically Accessible Scaled-Version of a Longwall Coal Mine for Investigating Explosion Hazards

| Contract # | 200-2017-94491 |

|---|---|

| Start Date | 8/24/2017 |

| End Date | 8/31/2020 |

| Research Concept |

This scale model will allow researchers to better study the flow of methane within a longwall mine environment and explore possible ventilation strategies to mitigate the risks of such an explosion. |

Contract Status & Impact

This contract is complete. To receive a copy of the final report, send a request to mining@cdc.gov.

Mine explosions continue to be a concern, both in the U.S. and abroad. The circumstances of mine explosions vary, but they frequently involve methane-air mixtures being ignited near the face areas of longwall mining equipment.

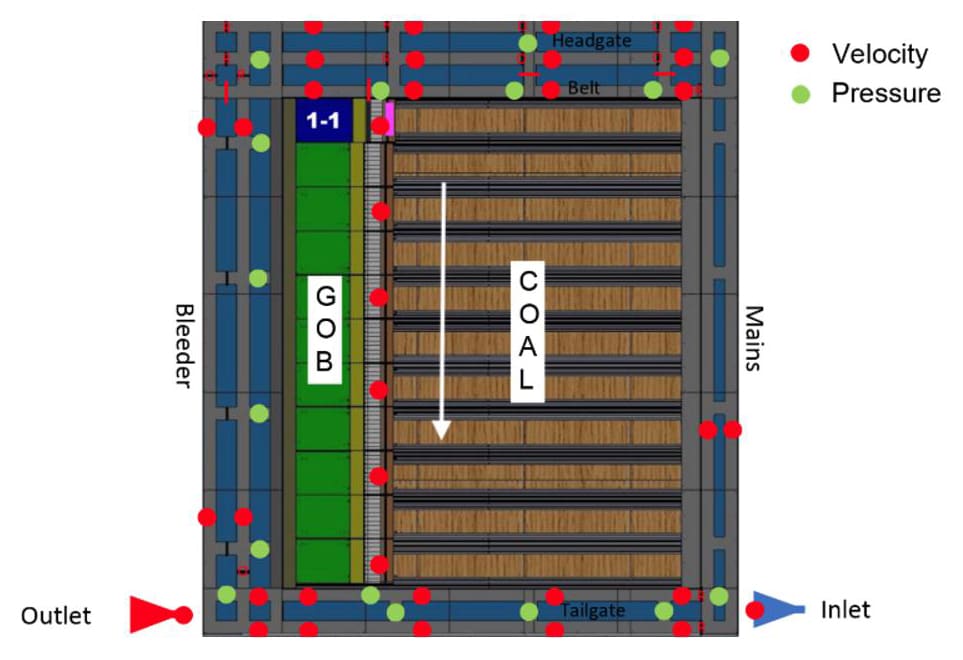

Overhead view of planned configuration for 1/40th scale model of a longwall mining section.

Computational fluid dynamics (CFD) models for longwall ventilation in coal mines have been developed in a composite approach using data from multiple field sites. Researchers from the Colorado School of Mines have investigated several aspects of longwall ventilation in detail using CFD modeling. While these models have found general acceptance, it is difficult to account for the variability of mining conditions. Field studies are one the most effective and accurate way to investigate longwall ventilation. NIOSH has recently conducted detailed tracer gas field studies at three U.S. longwall mines [1-3]. However, the complexity of active longwall mine ventilation systems makes it difficult to conduct accurate and detailed field experiments for a range of different mining configurations.

Consequently, NIOSH has developed the Longwall Instrumented Aerodynamic Model (LIAM), a physical model to conduct more conventional ventilation experiments, at the Pittsburgh Mining Research Division [4-5]. Building on the physical modeling research, this contract proposes to develop a 1/40th scale model of a longwall mining section that extends to include the ability to safely introduce actual flames and explosions in the model. Ignitions of methane/air mixtures are planned within the model and will be visually observable, as well as quantification of the location and migration of events with appropriate sensors.

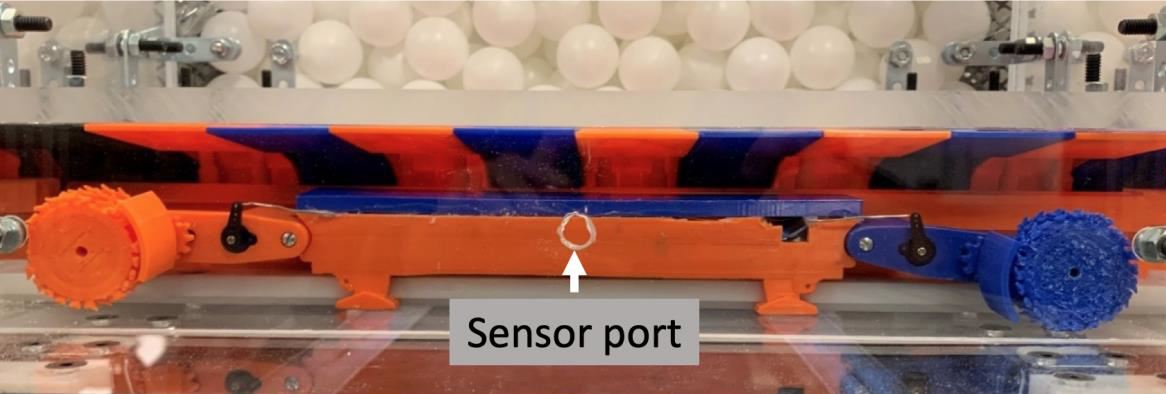

Longwall shearer and central sensor location on model's mine face. Also shown are simulated longwall shields and gob material (spheres) in the 1/40th scale model.

The work will address the need for an improved mine-wide Atmospheric Monitoring Systems (AMS), and provide the ability to link existing mine ventilation system (MVS) models with AMS in real time. The work will provide insight into the optimal placement of sensors based on ventilation and mine layout scenarios, along with providing insight into the potential hazards of a methane explosion and how the design of ventilation and mine layout could have an impact on the severity of an explosion. This new information could assist mine rescuers for post-disaster activities as well as provide practical guidelines with respect to explosion hazards that could be used at the start of a mine operation to assist in the design and operation of the mine contributing to strategies used in the mitigation and prevention of explosion hazards. This research can also provide important findings for the potential application of novel ventilation technologies such as the use of booster fans in underground coal mining or drift ventilation via smart ventilation controls. This research effort will provide crucial data that can be used to determine the feasibility of implementing a true mine-wide monitoring system that could prevent mine disasters or facilitate recovery efforts.

The explosive gas region will be identified via gas detection. The system will have the ability to vary the location of ignition in and around the longwall mine and Explosive Gas Zones (EGZs). The methane explosion will be observed optically and via flame sensors allowing detailed tracking of the movement of the explosion throughout the scaled-version of the longwall coal mine. This information may help ventilation engineers improve face ventilation and methane monitoring to prevent face ignitions, which could thereby save lives.

References:

- Schatzel SJ, Krog RB, Dougherty H (2017) Methane emissions and airflow patterns on a longwall face: potential influences from longwall gob permeability distributions on a bleederless longwall panel. Transactions of the Society for Mining, Metallurgy, and Exploration, Inc. Volume 342(1): 51–61

- Schatzel SJ, Gangrade V, Hollerich CA, Addis JD, Chasko LL (2019). Face Ventilation on a Bleederless Longwall Panel. Mining, Metallurgy & Exploration. https://doi.org/10.1007/s42461-019-0049-7

- Gangrade V, Schatzel SJ, Harteis SP (2019). A Field Study of Longwall Mine Ventilation Using Tracer Gas in a Trona Mine. Mining, Metallurgy & Exploration. https://link.springer.com/article/10.1007/s42461-019-0096-0

- Gangrade V, Harteis SP, Addis JD (2017) Development and applications of a scaled aerodynamic model for simulations of airflows in a longwall panel. In: proceedings of 16th North American Mine Ventilation Symposium. Golden, CO: Colorado School of Mines. pp. 6-17–6-24

- Gangrade V, Schatzel SJ, Harteis SP, Addis JD (2019). Investigating the Impact of Caving on Longwall Mine Ventilation Using Scaled Physical Modeling. Mining, Metallurgy & Exploration.

- Analysis and Design Considerations for Superimposed Longwall Gate Roads

- Benchmarking Longwall Dust Control Technology and Practices

- Degasification System Selection for U.S. Longwall Mines Using an Expert Classification System

- Development of Stress Measurements and Instrument Placement Techniques for Longwall Coal

- Horizontal Stress and Longwall Headgate Ground Control

- Investigating the Impact of Caving on Longwall Mine Ventilation Using Scaled Physical Modeling

- Local Earthquake Tomography for Imaging Mining-Induced Changes Within the Overburden above a Longwall Mine

- Modeling and Prediction of Ventilation Methane Emissions of U.S. Longwall Mines Using Supervised Artificial Neural Networks

- Overview of Coal Mine Ground Control Issues in the Illinois Basin

- Reservoir Engineering Considerations for Coal Seam Degasification and Methane Control in Underground Mines

- Studying Longwall Ventilation with Physical Modeling