Volunteer Fire Fighter Dies Following Nitrous Oxide Cylinder Explosion While Fighting a Commercial Structure Fire - Texas

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

Death in the Line of Duty…A summary of a NIOSH fire fighter fatality investigation

F2003-03 Date Released: November 7, 2003

SUMMARY

On January 19, 2003, a 32-year-old volunteer fire fighter died while fighting a structure fire at a specialized vehicle restoration shop. Soon after beginning interior attack operations, the fire intensified and rolled over the heads of the 4-member crew. Within minutes, the nozzleman had to exit the building due to burning hands and another fire fighter took the nozzle. As he was exiting, an air horn was sounded warning the crew to exit the building. Two of the three remaining crew members made it to safety. Less than a minute after they exited, a nitrous oxide cylinder that was attached to a race car in the building exploded. A Rapid Intervention Crew (RIC) was assembled to rescue the missing fire fighter (the victim). The RIC made two attempts to rescue the victim but had to exit because of the intensity of the fire. After approximately 40 minutes of master stream application, three teams entered the structure and found the victim lying near the office door. The alarm for his Personal Alert Safety System (PASS) device was functioning but was not audible due to his prone position.

NIOSH investigators concluded that, to minimize the risk of similar occurrences, fire departments should

- develop and enforce standard operating procedures (SOPs) for structural fire fighting that include, but are not limited to, Accountability, Rapid Intervention Crews (RIC), and Incident Command System

- ensure that a complete size-up is conducted before initiating fire fighting efforts, and that risk versus gain is evaluated continually during emergency operations

- ensure that team continuity is maintained

- ensure that the Incident Commander maintains the role of director of fireground operations and does not become involved in fire-fighting efforts

- ensure that an adequate fire stream is maintained based on characteristics of the structure and fuel load present

- ensure that pre-incident planning is done on commercial structures

- establish and maintain training programs for emergency scene operations

- review dispatch/alarm response procedures with appropriate personnel to ensure that the processing of alarms is completed in a timely manner

In addition,

- manufacturers and researchers should continue to refine existing and develop new technology to track and locate lost fire fighters on the fireground

Incident Scene

INTRODUCTION

On January 21, 2003, the U.S. Fire Administration (USFA) notified the National Institute for Occupational Safety and Health (NIOSH) of this incident. On February 10-13, 2003, two safety and occupational health specialists and a safety engineer from the NIOSH Fire Fighter Fatality Investigation and Prevention Program investigated the incident. The NIOSH team met with the department Chief, fire fighters who were directly involved in the incident, and the State and County Fire Marshals. The team visited and took photographs of the site of the fire. NIOSH investigators reviewed the victim’s training records, witness statements, and the Fire Marshals’ photographs and records concerning the incident, including preliminary autopsy findings.

Department: This volunteer fire department has 48 uniformed personnel within 3 stations and serves a population of approximately 13,540 in an area of about 90 square miles.

Training: The 32-year-old victim had been a volunteer fire fighter for 1 year and 4 months. He had completed over 400 hours of training, including the 70+ hours required by the State Firemans’ Association for interior attack, and NFPA Fire Fighter Levels I and II.

Weather Conditions: The weather was clear with calm winds and a temperature of 24o F at 7:00 a.m. on the day of the incident.

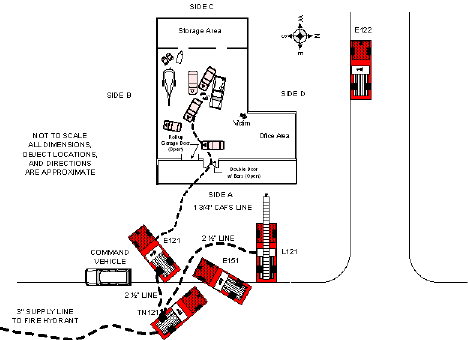

Apparatus: Apparatus on the scene at the time of the initial attack are listed below. Additional units arrived during and after the first evacuation signal and the subsequent explosion; however, only those that were involved up to this point are listed below.

1007 hours

- Incident Commander, Command Vehicle

1009 hours

- Engine 121 (E121) [first-due dept.] – Driver/Operator, 1 officer, 4 fire fighters (including victim)

1011 hours

- Engine 151 (E151) [volunteer mutual-aid] – Driver, 1 fire fighter, 1 junior officer

- Ladder 121 (L121) [first-due dept.] – 1 Driver/Officer

- Engine 122 (E122) [first-due dept.] – Driver/officer, 2 fire fighters, District Chief

- Tanker 121 (TN121) [first-due dept.] – 1 Driver/Officer

- Privately Owned Vehicle (POV) – 1 fire fighter/Emergency Medical Technician (EMT)

At approximately 1019 hours, an engine company and a ladder company from a mutual-aid career department arrived and assembled a Rapid Intervention Crew (RIC). A total of 75 fire service personnel eventually responded to this two-alarm fire.

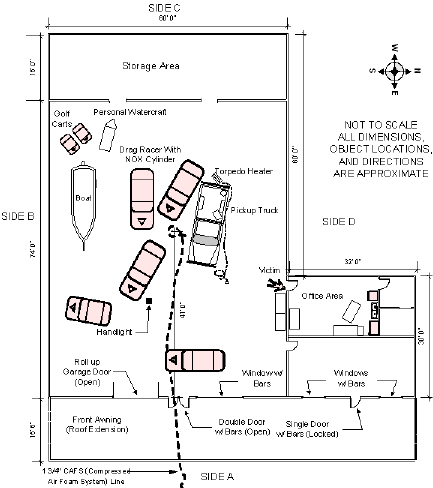

Structure: The structure was a one-story, flat-roofed, Type IV commercial building with a 30-foot by 32-foot extension on the north (D) side that contained office and restroom facilities (Diagram 1). Originally constructed in 1975, the building had undergone several additions and renovations. At the time of the incident, the building housed a new business (not yet opened) that was going to display specialized vehicles, and sell racing supplies and performance parts. The main showroom encompassed approximately 4,440 square feet. The rear of the building contained a 16-foot wide storage room that was originally a covered porch. Total frontage facing the highway was 92 feet. The west (rear or Side C) was 60 feet wide. A 15-foot 6-inch roof extension covered with aluminum provided an awning over the front of the building. At the time of the incident, minor renovations were taking place which included laying ceramic tile on the floor at the rear of the main showroom.

The east side (front or Side A) was constructed of concrete block. The remaining walls were wood-framed and covered with aluminum and sheet metal siding. The roof beams were constructed of 3 sandwiched 2-inch by 10-inch wooden boards supported by the exterior walls and equally-spaced steel posts throughout the interior. Gypsum drywall covered most of the underside of the roof deck. Roof beams were exposed in some areas. The outer surface of the wooden roof deck was protected by built-up layers of tar. A concrete slab partially covered with ceramic tile provided the floor surface.

The main entrance to the building was via outward-swinging double glass doors located in the center of the main building, Side A (Photo 1). A roll-up garage door was located immediately to the left of the glass doors which provided vehicle access. A single door located to the right of the main entrance provided access from the outside into the office area. All doors and windows were covered with metal security bars.

At the time of the incident, the building housed 5 cars, a 21-foot fiberglass boat, a personal water craft, and two golf carts (Diagram 1). One of the 5 cars was a drag racer that was equipped with a nitrous-oxide (N2O) fuel booster system. Additionally, there were numerous spray cans, lubricants and other flammable items, many of which were in cardboard boxes and stored on wooden pallets. The enclosed storage area at the rear of the building contained a variety of auto parts, lawn mowers, a motorcycle, and industrial tools. The owner’s 1-ton pickup truck was also in the showroom and was being used to haul supplies for the floor renovation work.

Personal Protective Equipment (PPE): The Self Contained Breathing Apparatus (SCBA) and turnout gear of the victim and the injured fire fighters were examined by NIOSH investigators. Due to the extensive damage to the equipment, no testing was conducted. However, no evidence was found suggesting that PPE performance contributed to the fatality. The victim was wearing a functioning integrated Personal Alert Safety System (PASS) device which initially could not be heard due to the victim’s prone position.

INVESTIGATION

On January 19, 2003 at 0959 hours, this volunteer fire department was dispatched to a commercial fire. Note: According to the contractor who was working on the building, on the morning of the fire, he was preparing a section of concrete floor for installation of ceramic tile – an approximately 400-square-foot area in the rear of the building – by pouring lacquer thinner onto the floor. He let the solvent sit for about 15 to 30 minutes and then decided to use a torpedo heater (kerosene/diesel blower type) to speed up the drying process. The heater was located at the rear of a pickup truck (Diagram 1) and the cord was extended to an outlet about 10 feet in front of the truck, toward the front of the building. As soon as the heater was plugged in, the solvent vapors ignited and a fire developed and quickly spread.

At 0959 hours, the first-due volunteer department and an automatic mutual aid volunteer department were dispatched to a commercial structure fire. The Chief of the first-due department was the first to arrive on the scene in a Command Vehicle at approximately 1007 hours. He assumed Incident Command (IC), reported heavy black smoke visible from the rear of the building, and requested two additional tankers, and a second alarm. He then helped set up the compressed air foam system (CAFS) and started pulling hose. Next to arrive was E121 at 1009 hours from the first-due department, followed at 1011 hours by E151 from the automatic mutual aid department and a ladder truck, an engine, and a tanker from the first-due department. A water supply line was established at a nearby hydrant by TN121 (Diagram 2). Two fire fighters from E121 pulled a 1 ¾ –inch hose line from the engine and approached the front entrance (double glass doors) in preparation for entering the structure. As soon as they arrived, two members of E151 joined the interior attack crew. Another fire fighter from E121 stood in the doorway holding the door open and feeding hose.

The attack crew entered the building through the glass double doors (Photo 1) with the charged 1 ¾-inch pre-connect using Class A compressed air foam at about 0.6%. Upon entering, light smoke was present from floor to ceiling. The rollup door was opened as they entered and the smoke cleared somewhat. The crew advanced into the building between the cars approximately 60 feet (Diagram 1). Note: At some point a positive pressure fan was set up at the entrance to the rollup door; however, it is unclear how long it was operating.

Shortly after entering the structure, the victim went back to the door (front of building) to obtain a handlight. He returned with the handlight and moved toward the front of the hose line. As soon as the nozzleman opened the nozzle, the fire increased and rolled to the left and then up and over the attack crew. Shortly thereafter, the nozzleman indicated to the crew that his hands were burning and that he had to leave immediately. As he proceeded to leave, the fire fighter behind him took the nozzle. The fire fighter with the burned hands escaped from the building through the roll up garage door throwing off his burning gloves as he neared the exit. The remaining interior crew members continued to fight the fire which continued to roll over their heads. At about the same time as the first crew member exited the building, an evacuation air horn was sounded for the crew to exit. Note: Fire fighters state that the fire was from floor to ceiling with thick, black smoke at this time. While exiting, one of the fire fighters removed his helmet and facepiece because his lens was crazing over. He escaped with serious burn injuries to his face, neck, chest and arms as well as damage to his gear and was taken to the hospital for treatment. Another member of the crew escaped with minor burn injuries to his hands and forearms (and with damage to his gear); he was treated at the scene. Approximately 30 seconds after the last crew member exited, a nitrous oxide cylinder that was attached to a race car in the building exploded. (The Appendix includes a description of the nitrous oxide cylinder, estimates of the forces generated by the exploding cylinder, and physiologic effects associated with such forces). A second 1 ¾-inch hose line had been pulled from E121 but had not been charged prior to the initial evacuation and subsequent explosion.

It was quickly realized that one member of the attack team had not exited the building. A RIC, consisting of 4 fire fighters from a mutual-aid career department which had arrived at 1019 hours, assembled to search for the missing fire fighter. The RIC entered the building and went about 10 feet following the hoseline. Although visibility was poor, they could see that the area to the right was not yet fully involved but that the entire rear of the building was on fire from top to bottom. After searching for a few minutes, a second evacuation alarm was sounded and the RIC had to exit as aerials were set up. Elevated streams were used to knock down the fire and the RIC was able to do a second search in which they made it to the rear of the building. The crew searched on both sides of the vehicles but did not find the victim. This second search, which lasted for about 5 minutes, was called off due to fire intensity and periodic water loss. The water loss was attributed to several factors including the fact that the hydrant line was hooked up to the tank fill inlet instead of the pump inlet (and, therefore, was not as efficient as if hooked straight to the pump), the hydrant valve was not fully opened, and leakage was occurring at the wye connection on one of the pre-connect hose lines. Master streams were used to knock down the fire and, after approximately 40 minutes, three teams of two fire fighters each entered the structure and located the deceased victim.

The victim’s last known location, prior to the first evacuation signal, was standing next to a crew member with one hand on the crew member’s shoulder while holding a flashlight in the other hand. The victim apparently became disoriented and lost. He was found lying prone near the doorway to an interior office. He was not wearing gloves which were later found near the door of this office. The victim had on his SCBA mask but the mask-mounted regulator was not attached. The alarm for his integrated PASS device, which had not been heard during previous searches due to the victim’s position, became audible when the victim was lifted. Soot was present on the victim’s face and inside his mouth and nose. Because the SCBA equipment was too damaged to examine, it is unknown if the victim’s tank had air in it. The preliminary autopsy findings indicated that he had received significant blast injuries, i.e., both eardrums were ruptured and there was concussive damage to his lungs.

CAUSE OF DEATH

Autopsy findings indicate that the cause of death was thermal injuries, with smoke inhalation and blast effect.

RECOMMENDATIONS/DISCUSSIONS

Recommendation #1: Fire departments should develop and enforce standard operating procedures (SOPs) for structural fire fighting that include, but are not limited to, Accountability, Rapid Intervention Crews (RIC), and Incident Command System.1-5

Discussion: SOPs are organizational directives or plans that establish how the organization will react in various situations to increase the effectiveness and ensure the safety of the firefighting team. Standard fireground procedures include but are not limited to basic command functions; delegation of command responsibility; communications and dispatching; fire ground safety; tactics; initial resource deployment; and designation of roles and responsibilities of companies and units. SOPs should be comprehensive and encompass training, fire protection agreement plans, and procedures for those incidents involving mutual and automatic aid. SOPs should be written, periodically reviewed, and enforced.

Accountability: According to NFPA 1720 § 4.2.1.3 “the incident commander shall ensure that a personnel accountability system is immediately utilized to rapidly account for all personnel at the incident scene.” At the start of operations, a company officer must record every responding fire fighter, including him or herself. If a collapse or explosion occurs on the fire ground, each officer will be asked to conduct a roll call and verify the whereabouts of personnel. In this incident, two of the mutual aid responders went directly to the hose line to join the attack crew without reporting to the IC and an accountability system was not set up until after the explosion.

Rapid Intervention Crew: During a fire, a Rapid Intervention Crew (RIC) should be standing by to rescue trapped, injured, or missing personnel. The RIC should report to the IC and remain at the staging area until an intervention is needed to rescue a fire fighter. The RIC should have all the tools necessary to complete the job, e.g., personal protective equipment, search rope and resuscitator, and should not be involved in fire suppression activities. In this incident, a RIC was not in place before the interior attack was begun.

Incident Command System: NFPA 1720 § 4.2.1.2 states that “the Incident Commander shall be responsible for the overall coordination and direction of all activities for the duration of the incident.” It is important that specific tasks and responsibilities are addressed in SOPs so that responding crew members know what their tasks are upon arrival and that the IC or company officer be prepared to assign responsibilities as needed on the scene. The recommended span of control (the number of personnel one can effectively supervise) is 4-7. Thus, as the number of personnel increases, the IC must delegate specific duties and tasks such as ventilation, search & rescue, and fire attack. In this incident, functions were not formally assigned.

Recommendation #2: Fire departments should ensure that a complete size-up is conducted before initiating fire fighting efforts, and that risk versus gain is evaluated continually during emergency operations.4, 6-9

Discussion: One of the most important size-up duties of the IC or first arriving officer is locating the fire and determining its severity. Size-up determines the resources needed to control the blaze, assists in determining the most effective point of fire extinguishment attack, and provides information for the most effective method of fire suppression. A proper size-up begins from the moment the alarm is received, and continues until the fire is under control. Factors to consider include characteristics of the structure (e.g., type of construction, age, type of roof system), time considerations (time of day, amount of time fire was burning before and after arrival), contents of the structure, potential hazards such as fuels or explosive materials, life safety hazards, and exposures. The initial size-up should include a complete 360º walk-around of the structure if possible.

Size-up includes a continual evaluation of the risk versus gain during operations. According to NFPA 1500 §A-6-2.1.1, “the acceptable level of risk is directly related to the potential to save lives or property. Where there is no potential to save lives, the risk to fire department members must be evaluated in proportion to the ability to save property of value. When there is no ability to save lives or property, there is no justification to expose fire department members to any avoidable risk, and defensive fire suppression operations are the appropriate strategy.” As Dunn (p.291) states “When no other person’s life is in danger, the life of the firefighter has a higher priority than fire containment.” This incident occurred early Sunday morning, the building was unoccupied, and was heavily involved in fire upon arrival of fire fighters.

Interior size-up. Since the IC is staged at the command post (outside), the interior conditions should be communicated as soon as possible and on a regular basis as they could alter the IC’s strategy and tactics. In this incident, no one was in charge of the attack crew and although one crew member had a radio, the interior crew did not communicate with the IC. The fire intensified as soon as the crew opened the nozzle. Shortly after this the nozzleman told the crew that he had to leave because his hands were burning. Communicating the changing interior conditions may have helped identify the deteriorating conditions more quickly and have caused the IC to order an evacuation signal sooner.

Recommendation #3: Fire departments should ensure that team continuity is maintained.10

Discussion: Team continuity involves knowing who is on your team and who is the team leader; staying within visual contact at all times (if visibility is obscured then teams should remain within touch or voice distance of each other); communicating your needs and observations to the team leader; rotating to rehab and staging as a team; and watching out for your team members (i.e., practice a strong “buddy-care” approach). Following these basic rules helps prevent serious injury or even death by providing personnel with the added safety net of fellow team members. Teams that enter a hazardous environment together should leave together to ensure that team continuity is maintained. In this incident, one crew member left due to burning hands and the rest of the crew remained until an evacuation signal was sounded.

Recommendation #4: Fire departments should ensure that the Incident Commander maintains the role of director of fireground operations and does not become involved in fire-fighting efforts.3, 11

Discussion: According to NFPA 1561, §4.1.1, “the Incident Commander shall be responsible for the overall coordination and direction of all activities at an incident.” In addition to conducting an initial size-up, the IC must assign companies and delegate functions. To effectively coordinate and direct fire-fighting operations on the scene, it is essential that adequate staff are available for immediate response to ensure that the IC is not required to become involved in fire-fighting efforts. In this incident the IC initially was involved in non-command functions such as pulling hose.

Recommendation #5: Fire departments should ensure that an adequate fire stream is maintained based on characteristics of the structure and fuel load present.7,10,12

Discussion: In addition to location and extent of the fire, factors affecting selection and placement of hose lines include the building’s occupancy, construction, and size. In addition, fire load and material involved, mobility requirements, and number of persons available to handle the hose lines, are important factors. Regardless of the choice of attack method or the type of fire stream used, successful fire suppression depends upon discharging a sufficient quantity of water to remove the heat being generated, and ensuring that it reaches the fire rather than being turned into steam or being carried away by convective currents. A back-up line at least as large as the initial attack line, should be in place and charged before interior fire fighting efforts begin. Some experts recommend that a 2 ½-inch-line routinely be used with commercial and industrial structures if a sizable body of fire is present. The reasoning behind this is that, compared to a residence, the fire load in commercial structures is usually heavier, longer reaching and in need of harder hitting streams. In addition, it is more likely that hazardous and flammable materials are present. In this incident, periodic water loss was an issue because of water supply set up. Due to problems hooking up the water supply, there was a delay in setting up the second (1 ¾-inch) attack line.

Recommendation # 6: Fire departments should ensure that pre-incident planning is performed on commercial structures.2,13

Discussion: NFPA 1620 § 2-2.6.2 states “the pre-incident plan should be the foundation for decision making during an emergency situation and provides important data that will assist the incident commander in developing appropriate strategies and tactics for managing the incident.” This standard states that “the primary purpose of a pre-incident plan is to help responding personnel effectively manage emergencies with available resources. . . Pre-incident planning involves evaluating the protection systems, building construction, contents, and operating procedures that can impact emergency operations.” A pre-incident plan identifies deviations from normal operations and can be complex and formal, or simply a notation about a particular problem such as the presence of flammable liquids, explosive hazards, or structural damage from a previous fire. NFPA 1620 outlines the steps involved in developing, maintaining, and using a pre-incident plan by breaking the incident down into pre-, during- and after-incident phases. In the pre-incident phase, for example, it covers factors such as physical elements and site considerations, occupant considerations, protection systems and water supplies, and special hazard considerations.

In this incident, no pre-incident planning had been performed for this structure. Some of the arriving companies were unaware and others were only vaguely aware of the contents of the building.

Recommendation # 7: Fire departments should establish and maintain training programs for emergency scene operations.6, 14-16

Discussion: Fire departments should consult sources such as NFPA 1410 Standard for Training for Initial Emergency Scene Operations; NFPA 1500 Standard on Fire Department Occupational Safety and Health Program, and NFPA 1002 Standard for Fire Apparatus Driver/Operator Professional Qualifications. IFSTA’s Pumping Apparatus DRIVER/OPERATOR Handbook also provides guidance on safe, effective operation of the pump to produce effective fire streams.

In this incident, loss of water pressure was a recurring problem for several reasons. For example, initially the hydrant line was hooked up to the tank fill inlet instead of the pump inlet (thus, decreasing its efficiency), the hydrant valve was not fully opened, and leakage was occurring at the wye connection on one of the pre-connect hose lines. This was the first time the driver/operator of E121 had driven and operated that particular apparatus.

Recommendation #8: Fire departments should review dispatch/alarm response procedures with appropriate personnel to ensure that the processing of alarms is completed in a timely manner.17

Discussion: NFPA 1221 Section 6.4.2 states “ninety-five percent of alarms shall be answered within 15 seconds, and 99 percent of alarms shall be answered within 40 seconds.” Section 6.4.3 states “ninety-five percent of emergency dispatching shall be completed within 60 seconds.” Section 6.4.6 states “in cases where the communications center is not the primary answering agency . . . for alarms, the answering agency shall transfer alarms as follows: (1) the alarm shall be transferred directly to the telecommunicator; (2) the answering agency shall remain on the line until it is certain that the transfer is effected; and (3) the transfer procedure shall be used instead of relaying the information to the communications center.” In this incident the request for mutual aid from the career department was delayed for approximately 7 minutes due to procedural issues at the dispatch center. The career department that experienced the delay was aware of this problem and was addressing it at the time of the NIOSH site visit.

Recommendation #9. Manufacturers and researchers should continue to refine existing and develop new technology to track and locate lost fire fighters on the fireground.18-22

Discussion: Fire fighter fatalities often result after fire fighters become disoriented and/or lost on the fireground. In this and a previous incident investigated by NIOSH, the lost victims were found lying prone with their PASS device alarms functioning, but inaudible to the search and rescue teams due to the victim’s prone posture. One approach to this particular problem is to use a distributive system in which PASS devices are placed on the front and back of the fire fighter to increase the probability that the alarm can be heard by rescuers whatever the posture. Another approach is to supplement the regular PASS device with an acoustic device that emits sounds above the threshold of human hearing (ultrasonic). Such devices emit sounds that can be detected by tracking devices and have been investigated in fire fighter training scenarios. Yet another possibility to consider is the use of electro-magnetic systems. Extremely Low Frequency (ELF), Very Low Frequency (VLF) and Low Frequency (LF) electro-magnetic systems that emit signals in the 0 to 300 kHz range have been tested and found useful as location devices for locating trapped miners and in ski patrol rescue.

REFERENCES

- Cook, JL [1998]. Standard operating procedures and guidelines. Saddle Brook, NJ: PennWell Publishing.

- NFPA [2001]. NFPA 1720: standard for the organization and deployment of fire suppression operations, emergency medical operations, and special operations to the public by career fire departments. Quincy, MA: National Fire Protection Association.

- NFPA [2002]. NFPA 1561, standard on fire department incident management system. Quincy, MA: National Fire Protection Association.

- Brunacini AV [1985]. Fire command. Quincy, MA: National Fire Protection Association.

- Smoke CH [1998]. Company officer (Ch. 5). Albany, NY: Delmar Publishers.

- NFPA [2002]. NFPA 1500: standard on fire department occupational safety and health program. Quincy, MA: National Fire Protection Association.

- Dunn V [1992]. Safety and survival on the fireground. Saddlebrook, NJ: Fire Engineering Books & Videos.

- Norman J [1998]. Fire officer’s handbook of tactics, 2nd ed. Saddle Brook, NJ: PennWell Publishing Company.

- International Fire Service Training Association [1992]. Essential of fire fighting, 3rd ed. Stillwater OK: Fire Protection Publications.

- National Fire Academy Alumni Association [2000]. Firefighter’s handbook: Essentials of firefighting and emergency response. Albany, NY: Delmar.

- Page JO [1973]. Effective company command for company officers in the professional fire service. Alhambra, CA: Borden Publishing Co.

- Klaene BJ, & Sanders RE [2000]. Structural fire fighting. Quincy, MA: National Fire Protection Association.

- NFPA [1998], NFPA 1620, recommended practice for pre-incident planning. Quincy, MA: National Fire Protection Association.

- NFPA [2000]. NFPA 1410: fire service vehicle operation training program. Quincy, MA: National Fire Protection Association.

- International Fire Service Training Association [1999]. Pumping apparatus driver/operator handbook. 1st ed. Stillwater OK: Fire Protection Publications.

- NFPA [1998]. NFPA 1002, standard for fire apparatus driver/operator professional qualifications. Quincy, MA: National Fire Protection Association.

- NFPA [1999]. NFPA 1221, standard for the installation, maintenance, and use of emergency services communications systems. Quincy, MA: National Fire Protection Association.

- NIOSH [2002]. Volunteer fire fighter killed and career chief injured during residential house fire–Tennessee. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, NIOSH, DHHS (NIOSH) Publication No. F2002-12.

- Nasta M [2003]. Mayday training. Fire Engineering. August issue.

- Nessler NH [2000]. Electromagnetic location system for trapped miners. Subsurface sensing technologies and applications 1(2). April issue.

- Walter J [2003]. Feature reviews: avalanche beacons. Gearreview.com. http://www.gearreview.com/beacons.aspexternal icon Date accessed: October 7, 2003.

- NFPA [1998]. NFPA 1982, standard on personal alert safety systems (PASS). Quincy, MA: National Fire Protection Association.

INVESTIGATOR INFORMATION

This incident was investigated by Linda Frederick and Mark McFall, Safety and Occupational Health Specialists, and Tim Merinar, Safety Engineer, Division of Safety Research, Surveillance and Field Investigations Branch, NIOSH.

Photo 1. Fire fighters preparing to enter fire building.

Photo 2. Fragments of the exploded nitrous oxide cylinder.

Diagram 1. Structure contents and location of victim.

Diagram 2. Approximate position of apparatus and hoses at time of critical incident.

Appendix

Explosion of Nitrous-oxide Fuel Booster System

To assess the potential contributory role of the exploded nitrous oxide cylinder in the fire fighter death, an analysis was undertaken to estimate the forces generated by the explosion, and physiologic effects that could be anticipated under such forces. Estimates of the blast forces and findings from the investigation and autopsy are consistent with the deceased fire fighter sustaining injuries from the nitrous oxide cylinder explosion that may have contributed to him not exiting the building.

Fuel Booster System: The booster system consisted of a cylinder, regulator, control valve and hose line connected to the engine’s carburetor to inject nitrous oxide into the fuel stream. Nitrous oxide breaks down into nitrogen and oxygen when heated. The oxygen enhances the combustion of the liquid fuel within the gasoline engine, providing a boost in horsepower and performance.

The cylinder was a U.S. Department of Transportation (DOT) 3AL solid aluminum cylinder manufactured in June 1987 and, based on the date of manufacture, constructed of 6351-T6 aluminum alloy. The cylinder was rated for 1800 psi and designed to contain up to 10 pounds of liquid nitrous oxide or approximately 45 feet3 of gaseous nitrous oxide. The Compressed Gas Association (CGA) website http://www.cganet.com/N2O/factsht.htm classifies Nitrous Oxide (N2O) as a nonflammable gas that supports combustion and will detonate at temperatures in excess of 650 degrees C (1202 degrees F).

Blast estimate: The exploding nitrous oxide cylinder was torn into 3 fragments, the bottom, the top with most of the wall, and the rest of the wall (Photo 2). The approximate force generated by the exploding cylinder can be calculated if a number of assumptions are made. The pressure within the cylinder at the time of the fire is not known, but the worst case scenario would be to assume it was full. The cylinder was marked “10 lbs” which indicated it was to be filled with 10 pounds of N2O. The temperature in the fire was well over 1000 degrees F based upon thermal damage to the protective equipment worn by the 3 fire fighters who escaped.

The decomposition of N2O to the elements (N2 + 1/2 O2) releases 446 cal/g of thermal energy – as compared to about 1.1 Kcal/g for TNT. The N2O decomposition energy is thus 41% that of TNT. If the N2O cylinder contained 5.2 pounds, that is equivalent (energetically) to 2.1 pounds of TNT. If filled with 10 pounds of liquid N20 (per the label), that is equivalent to 4.1 pounds of TNT. Thus, every pound of N2O contained in the cylinder is equivalent to 0.41 pounds of TNT.

The cylinder easily would be overpressurized if an appreciable part of the liquid content were vaporized by the heat from the surrounding fire. Each pound vaporized contributes about 8.5 atm or 124 psi at 1000 degrees Kelvin (1340 degrees F). If the maximum of 10 pounds is vaporized that corresponds to 85 atm or 1240 psi. The temperatures reached in the exothermic decomposition are much greater, and Pa/Po = 1.5 Tb/To. This type of cylinder is tested to 5/3 the rated working pressure (5/3 X 1800 psi = 3000 psi). Assuming the cylinder was fully pressurized to 1800 psi at the time of the fire, the internal cylinder pressure could have exceeded 3000 psi. The pressure rise was, apparently, great enough to overcome the relief valve venting. At the time of this report, the cylinder has been impounded as part of a criminal investigation and the condition of the pressure relief device has not been determined.

Physiological effects: The cylinder rupture would release a pressure wave radiating outward. Assuming the cylinder was completely full, the cylinder exploded with a force equivalent to as much as 4 pounds of TNT. At a distance of 10 feet from the exploding cylinder, the fire fighter could have been exposed to a shock wave of up to 30 psi. This is well above the threshold level for eardrum rupture and internal lung damage. Studies indicate the presence of tympanic membrane (ear drum) rupture is associated with a blast pressure wave of at least 6 psi. The threshold for lung injury is 15 psi. The intensity of an explosion pressure wave declines with the cubed root of the distance from the explosion. Thus, a person 3 m (10 feet) from an explosion experiences 9 times more pressure than a person 6 m (20 feet) away. The effects of a blast overpressure shock wave are increased when explosions occur in closed or confined spaces such as inside a building or a vehicle. Blast waves are reflected by solid surfaces. Thus a person standing next to a wall or vehicle may suffer increased primary blast injury.c

a P = Final Pressure, Po = Pressure at origin

b T = Final Temperature, To = Temperature at origin

c Lavona E [2003]. Blast Injuries. [http://emedicine.medscape.com/article/822587-overviewexternal icon] Date accessed: June, 17, 2003. (Link Updated 1/16/2013)