Cured-in-Place Pipe

Cured-in-place pipe (CIPP) is a method of repairing pipelines that requires less digging than traditional techniques. It is versatile and used in waste and storm water pipelines. Use of CIPP first began in the 1970s and it has grown significantly in popularity. Learn more about hazards associated with CIPP that might put workers’ health at risk if they are not protected.

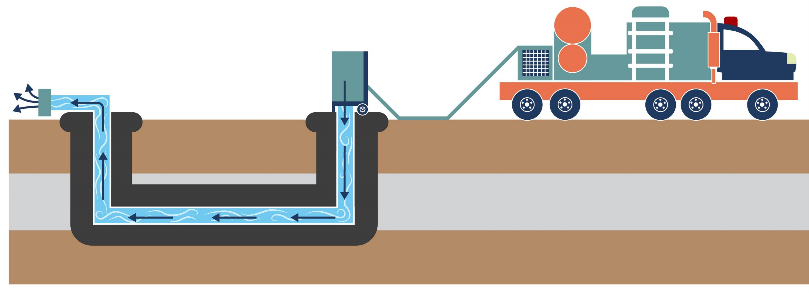

Image by NIOSH

How does CIPP work?

CIPP is installed by inserting liners into existing pipelines and then hardening or “curing” them during installation, or when they are “in place.” This is why the method is called cured-in-place pipe.

First, workers make a chemical mixture to put inside the liner. The ingredients of this mixture can vary, but it often contains styrene, resin, and a catalyst. Styrene is commonly used to make plastics and rubber. This mixture forms a substance that will remain liquid until treated at the worksite.

Photo by NIOSH

Next, the mixture is injected into a tubular liner made of felt or other support material and is spread evenly throughout. Liners are usually kept in refrigerated trucks to keep them cool and stop them from hardening before the workers are ready.

Then, liners are transported to job sites and placed into older or broken pipes using compressed air, water pressure, or by pulling liners through the pipes. Liners are cured inside the older or broken pipe using steam, hot water, or ultraviolet light. After the liner is done curing, workers may need to trim the new pipe.

What are the potential hazards to workers?

The main chemical hazard for CIPP workers is styrene. Styrene is a part of the chemical mixture for the pipe liner. It has been classified as “probably carcinogenic” by the International Agency of Research on Cancer “based on limited evidence in humans and sufficient evidence in experimental animals for carcinogenicity.” Workers can be exposed to styrene by breathing it in or absorbing it through their skin. Styrene can cause:

- Nose, eye, and throat irritation

- Headaches

- Tiredness

- Slowed reaction time

- Changes in color vision

- Balance problems

- Concentration problems

- Hearing loss

Respiratory diseases, including asthma and obliterative bronchiolitis, have also been reported.

Another possible hazard of working with CIPP involves entering small, confined spaces such as manholes. Confined spaces have limited means for entries and exits, are not designed for continuous occupancy, and usually have no ventilation. Styrene can build up in confined spaces, making them dangerous due to potentially high levels of styrene and low levels of oxygen. It can also be difficult to remove a worker from a confined space if they have a medical emergency and are unable to leave on their own.

How can workers stay protected?

There are several measures workers and employers can take to reduce health hazards from CIPP.

Employers

- Ensure clear separation between work areas and rest areas.

- Ensure workspaces are well-ventilated.

- Monitor air quality and ventilation before workers enter confined spaces and while they are in the confined space.

- Conduct personal air monitoring on workers to ensure styrene concentrations remain below occupational exposure limits.

- Provide personal protective equipment (PPE) and PPE training to workers, such as respirators with organic vapor cartridges

- Use non-styrene-based resins, if possible.

- Provide workers education on chemicals they work with and potential health effects of exposure.

Workers

Ask your employer and supervisor for information about the hazards in your workplace and how to protect yourself.

- Isolate yourself from hazards as much as possible.

- Use protective gloves when handling CIPP materials.

- Never enter confined spaces without another worker monitoring you.

- Wear respiratory PPE as directed by your employer and supervisor

- Remain aware of your personal exposures.

- Encourage other employees to take similar precautions.

CIPP has many advantages over traditional pipe repair methods. However, it is important to recognize the health risks this method can have to workers and take steps to reduce exposure. Creating awareness and taking action can help protect this workforce and improve industry safety and health overall.

Related resources