A laborer for a framing subcontractor in Texas died when he fell from a wooden trash box being lifted by a forklift.

Texas FACE 98TX310

SUMMARY:

On June 6, 1998, a 21 year-old laborer (the victim) died when he fell from a wooden trash box being lifted by a rough terrain forklift. The victim was attempting to install the last piece of sheeting on the second floor of a house. Another worker went to get a forklift and a trash box for him to stand in while nailing up the sheeting. Once the trash box had been raised to the level of the missing sheeting, the victim stepped out from the second floor of the house and into the trash box. He then told the driver to reposition the forklift. As the driver repositioned the forklift, the box began to wobble, causing the victim to fall out of the box. The victim landed on the ground and the trash box fell striking him in the head. Local emergency medical services were notified at 5:38pm. Upon their arrival the victim was not responsive and had no vital signs. The coroner responded to the site and pronounced the victim dead at the scene.

The TX FACE investigator concluded that to reduce the likelihood of similar occurrences, employers should:

- Secure the rough terrain forklift to prevent unauthorized use.

- Ensure that rough terrain forklifts used for lifting personnel, when no other practical means are available, are equipped with stable lifting platforms and fall protection devices.

- Ensure that job safety analysis (JSA) are completed and that supervisors use them as guidelines for completing tasks and for training workers.

INTRODUCTION

On June 6, 1998, a 21 year-old laborer (the victim) died when he fell from a wooden trash box being lifted by a rough terrain forklift. The TX FACE program officer was made aware of the fatality by the regional OSHA office. On September 24, 1998, the TX FACE program officer visited the job site and met with the project managers for both the subcontractor and the general contractor. The victim’s employer was not available. The operator of the forklift was the only witness, but he had not been seen since the day of the incident.

Emergency medical services were contacted, but refused to release their report. The medical examiner was contacted and his autopsy report was acquired. Pictures were taken of a similar trash box and of the rough terrain forklift involved in the incident.

The employer was a framing subcontractor that had been in business for 19 years. The company employed four superintendents who supervised other subcontractors. At the time of the incident there were 12 other employees in the company who worked in the same occupation as the victim. One coworker was at the scene at the time of the incident. This was the first fatality the employer had experienced.

The company had a designated safety director. There was a written safety program, but there were no work procedures specific to the task being performed at the time of the incident. Tailgate talks were conducted weekly and included safety issues.

New hire training was conducted by the subcontractor. However, there was no refresher training or task-specific training. Job site talks were used to conduct training.

The victim had been employed by the company for three years and had performed and was trained to install exterior sheeting.

INVESTIGATION

The victim was working on a residential construction site for a subcontractor who installed sheeting on the outside of houses. It was the end of the workday and the victim wanted to hang the last piece of sheeting on a house. The piece of sheeting was going to be nailed over an opening on the second floor. The victim asked one of the other workers, employed with the same subcontractor, to go and get a forklift and a trash box. The victim wanted to use the trash box as a platform from which to stand and nail up the sheeting.

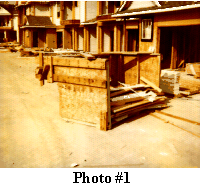

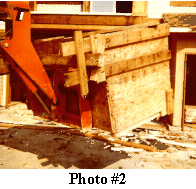

The trash boxes were four feet by eight feet and were made at the job site (see Photo #1). On the sides were the words “for trash only” in both English and Spanish. They were designed to stay on a forklift’s forks when their contents were dumped into a larger refuse container. This was accomplished by attaching a bar made of two 2×6’s to the back of the box. There was a 17-inch space between the bar and the back of the trash box. The forklift operator would position the face of the forklift’s carriage between the wooden bar and the back of the trash box (see Photo #2). The operator could then raise the box and tip it forward to empty refuse into a larger container.

In this incident, the coworker obtained a rough terrain forklift. He was able to start the forklift with a flattened nail which he stuck into the ignition switch. Due to the type of ignition switch installed by the manufacturer, a flattened nail could be used in place of the key. (Note: The manufacturer installed an ignition switch that required a key, but the key was a simple design with few indentations cut into it.)

Normally, the forklift was secured to prevent unauthorized use. The coworker was not authorized to operate the forklift. There was a trained and authorized operator for the rough terrain forklift working at the job site. However, that person had already left for the day.

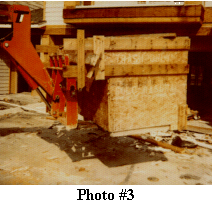

The coworker picked up the trash box without correctly positioning it on the forks. He did not place the face of the forklift’s carriage between the bar and the back of the box. Instead, he placed the face of the carriage against the back of the wooden bar (see Photo #3). This caused the front of the box to extend at least 20 inches over the tips of the forks. (Note: The forks were 47½ inches in length and the box was 48 inches deep. The space where the carriage is supposed to be positioned plus the thickness of the two 2×6’s add an additional 20 inches to the width of the box.)

When the coworker came back with the forklift, he raised the trash box so it was close to the opening on the second floor. The victim stepped into the trash box and told the coworker to reposition the forklift so he could nail up the last piece of sheeting. The forklift was on uneven hard packed dirt. When the coworker attempted to reposition the forklift, the movement caused the box to wobble and the victim fell out of the box to the ground. The box fell off the forks and struck the victim in the head.

Local emergency medical services were notified at 5:38pm. Upon their arrival the victim was not responsive and had no vital signs. The coroner responded to the site and pronounced the victim dead at the scene.

CAUSE OF DEATH

A doctor determined the cause of death was from crushed injury to head and neck and closed trauma to head.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should secure the rough terrain forklift to prevent unauthorized use.

Discussion: On previous job sites, the employer would sometimes secure motorized equipment such as forklifts in a fenced area. On the day of the incident the forklift was parked in an area where those working at the construction site had access to it.

The ignition switch installed on the forklift involved in this incident could be easily switched on with a flattened nail. That is how an unauthorized operator could operate the forklift without the ignition key. For this reason, a forklift should be secured behind a locked gate or the steering wheel chained to prevent it from being used by unauthorized operators.

Recommendation #2: Employers should ensure that rough terrain forklifts used for lifting personnel, when no other practical means are available, are equipped with stable lifting platforms and fall protection devices.

Discussion: The American Society of Mechanical Engineers in their standard ASME B56.6-1992, Safety Standard for Rough Terrain Forklift Trucks1, recommends rough terrain forklift trucks not be used to lift people unless there is not other practical option. If a rough terrain forklift truck must be used to lift people, the following precautions should be taken. For the full list see ASME B56.6-1992, para.5.15 (a)-(y).

- Provide a personnel platform which complies with the design requirements listed in Part III of the standard ASME B56.6-1992.

- Be certain that the platform is securely attached to the lifting carriage or forks.

- Be certain that the platform is horizontal.

- Never tilt platform forward or rearward when elevated.

- Be certain that required restraining means such as railings, chains, cable, and appropriate personal fall protection equipment are in place and properly used by trained employees.

- Always lower the platform if you must move the rough terrain forklift truck for adjustments in positioning.

Recommendation #3: Employers should ensure that job safety analysis (JSA) are completed and that supervisors use them as guidelines for completing tasks and for training workers.

Discussion: A JSA forces those conducting the analysis to view each operation as part of a system. In so doing, each step in the operation is assessed while consideration is paid to the relationship between steps and the interaction between workers and equipment, materials, the environment, and other workers. The JSA provides a clear model for completing jobs safely and. when followed, can help reduce injuries.

REFERENCES

- Safety Standard for Rough Terrain Forklift Trucks, ASME B56.6-1992, American Society of Mechanical Engineers

ILLUSTRATIONS

Please use information listed on the Contact Sheet on the NIOSH FACE web site to contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Back to NIOSH FACE Web