Asphalt Plant Trainee Dies in South Carolina Following a 3-foot Fall into a Drag Slat Conveyor

FACE 9119

SUMMARY

A 24-year-old asphalt plant trainee (victim) fell 3 feet into an unguarded drag slat conveyor and was crushed to death. At the time of the incident, the victim was one of four employees working at an asphalt plant. The victim and a co-worker were instructed to run aggregate through a conveyor in order to calibrate a scale used to weigh trucks. While the conveyor was operating, the victim climbed onto a support beam for the conveyor frame, to operate a handle controlling a gate in the conveyor chute. The support beam was located directly above an unguarded opening into the conveyor. While operating the handle, the victim apparently lost his balance and fell into the conveyor feet first. The co-worker was standing nearby, but was unable to free the victim or stop the operation of the conveyor. The victim was slowly pulled into the narrow aperture of this closed conveyor system and crushed between the rotating slats and the structure of the conveyor. The local coroner pronounced the victim dead inside the conveyor. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- ensure that all exposed moving machinery parts are guarded per the ASME/ANSI safety standards for conveyors and related equipment

- provide positive-acting stop controls along all conveyor systems

- provide handle extensions or elevated work platforms at all locations where climbing or standing on machinery is required to gain access

- conduct job safety analyses for all plant employees

- review and revise, where applicable, the safety program to include, but not be limited to, helping workers recognize, understand, and control hazards

- conduct scheduled and unscheduled safety inspections to ensure that safety procedures are being followed.

INTRODUCTION

On June 17, 1991, a 24-year-old asphalt plant trainee died after falling 3 feet into an unguarded drag slat conveyor. On June 20, 1991, officials of the South Carolina Occupational Safety and Health Administration (OSHA), notified the Division of Safety Research (DSR) of the death, and requested technical assistance. On July 11, 1991, a DSR safety specialist traveled to the incident site to conduct an investigation. The incident was reviewed with representatives from the company, co-workers of the victim, and the OSHA compliance officer assigned to the case. Photographs of the incident site were taken, and the medical examiner’s report was obtained.

The company was primarily engaged in highway construction and paving, and operated 12 of its own asphalt plants in 2 states. The company employed 350 workers, which included 12 asphalt plant trainees, and had a written safety policy, a written safety program, and general safety procedures. The safety coordinator, project superintendents, and area managers were responsible for the implementation of the safety program. The company required pre-employment physicals including drug screening. The victim had worked for the company for only 4 days prior to the incident.

INVESTIGATION

On the day of the incident, four employees-the plant foreman, an asphalt plant operator, a maintenance person, and an asphalt plant trainee (the victim)-arrived at the plant and began work as usual. A few hours had passed when a problem was noted with the calibration of the scale used to weigh trucks transporting the asphalt from the plant. The asphalt plant operator and asphalt plant trainee were instructed to assist in the recalibration procedures by clearing the conveyor of any remaining asphalt, and running aggregate (i.e., an inert material such as sand, pebbles, crushed rock, or gravel screened to size for use in road surfaces) through the drag slat conveyor (i.e., a conveyor employing one or more endless chains to which non-overlapping, non-interlocking spaced slats were attached).

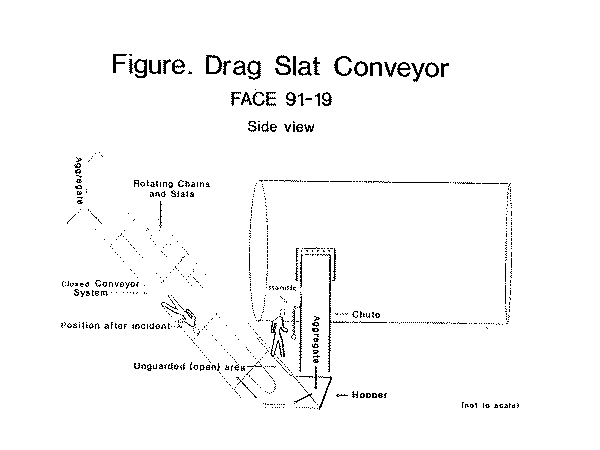

At the time of the incident, while the conveyor was operating, the victim climbed approximately 3 feet onto a support beam for the conveyor frame. The support was about 3 inches wide by 3 feet long by 1/8 inch thick, and positioned at a 45-degree angle. The beam was located directly above an unguarded opening for the conveyor (Figure).

The victim was standing on the support operating a handle (the length of the handle was such that it could not be operated from ground level) connected to a gate in the chute which released aggregate into the conveyor. The co-worker told the victim to “get down from there,” but the victim continued to operate the handle in an up and down motion. The victim apparently lost his balance and fell, feet first, into the drag slat conveyor. The co-worker grabbed the victim’s arm, but could not hold the victim from being dragged into the conveyor. The co-worker ran toward a trailer where the control panel for the conveyor was located. The foreman saw the co-worker running toward the trailer waving his arms, which was a signal that something was wrong. The foreman immediately shut off power to the conveyor, and ran to the worksite with the co-worker. After realizing the victim had been dragged approximately 10 feet into the conveyor, the foreman called the emergency medical service (EMS). The EMS arrived in 10 minutes, and immediately determined that nothing could be done to aid the victim. The coroner arrived about 35 minutes later and pronounced the victim dead in the conveyor. The victims remains were extracted from the conveyor and transported to the coroner’s office for an autopsy.

CAUSE OF DEATH

The medical examiner’s report listed the cause of death as multiple body trauma.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that all exposed moving machinery parts are guarded in accordance with ASME/ANSI B20.1-1987, 5.9.1.1 and 5.9.2 (1).

Discussion: The area between the conveyor and the aggregate discharge hopper was unguarded and presented a hazard of exposed moving machinery parts. The potential for identical hazards exists in all asphalt plants that are similar in operation and use conveyor systems. Employers should ensure that dangerous openings between pieces of equipment receive adequate guarding to protect employees from the hazards of exposed moving machinery parts.

Recommendation #2: Employers should provide positive-acting stop controls along all conveyor systems.

Discussion: All conveyor systems that are readily accessible present the potential for numerous hazards, especially that of being caught in moving machinery parts. Employers should provide positive-acting stop controls along all conveyor systems that are readily accessible and maintained so that the conveyor can be stopped or started at any location.

Recommendation #3: Employers should provide handle extensions or elevated work platforms at all locations where climbing or standing on equipment is required to gain access.

Discussion: The size and placement of handles that operate gates in chutes at all facilities should be inspected/revised in order to facilitate operation in a safe manner. If handle modifications are not possible, an elevated work platform with handrails can provide workers with safe access to handles.

Note: At this facility the length of the handle has since been extended, and the handle moved to the opposite side of the chute, to permit operation from ground level.

Recommendation #4: Employers should conduct job safety analyses (JSA) for all plant employees.

Discussion: A JSA is a safety analysis of all basic tasks performed by a person in a specific job category. JSA’s identify hazards that might interfere with the safe completion of employee tasks, and point to appropriate control measures.

Recommendation #5: Employers should conduct scheduled and unscheduled safety inspections regularly at each jobsite.

Discussion: Although the company had a written safety program and general safety procedures, scheduled and unscheduled safety inspections should be conducted on a regular basis. To be effective, a safety program must be enforced at the worksite. Regular company safety inspections followed by implemented changes demonstrate to workers that the company is committed to enforcing its safety policies and procedures.

Recommendation #6: Employers should review and revise, where applicable, the safety program to include, but not be limited to, helping workers recognize, understand, and control hazards.

Discussion: OSHA Standard 29 CFR 1926.21(b)(2) (2) states, “the employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” Employers should review and revise, where applicable, the safety program to address all hazards encountered by workers.

REFERENCES

1. ASME/ANSI B20.1-1987 – Safety Standard for Conveyors and Related Equipment, 5.9.1.1, and 5.9.2, P.8. The American Society of Mechanical Engineers, United Engineering Center, New York, N.Y.

2. 29 CFR 1926.21(b)(2) Code of Federal Regulations, Washington, D. C.: U.S. Government Printing Office, Office of the Federal Register.

Figure.