Millwright Foreman Dies in South Carolina Following a 41-foot Fall Through a Platform Opening

FACE 9115

SUMMARY

A 36-year-old millwright foreman (victim) fell 41 feet to his death through an unguarded platform opening. At the time of the incident, an open-sided steel structure had been constructed to support eight air-conditioning units on the platform. Four air-conditioning units had been installed and the fifth unit had been lifted into position by a crane. In order to level the unit, three millwrights were positioned on one side of the air-conditioning unit, while the victim was kneeling on the opposite side. The victim stood up and apparently tripped or stumbled and fell backwards landing on the steel grating of the platform walkway. Momentum from the fall caused the victim to roll into an adjacent opening which was about 17 feet long by 7 feet wide. The victim fell through the opening, struck a steel support crossbeam about 20 feet below, and fell an additional 21 feet to the ground. The victim was pronounced dead 4 hours later at the emergency room of a local hospital. NIOSH investigators concluded that, to prevent future similar occurrences, employers should:

- implement 29 CFR 1926.500 (b)(1) and 1926.500 (f)(5)(ii), which require that wherever there is danger of falling through a floor opening, it shall be guarded by a standard railing and toeboards on all exposed sides, or a cover capable of supporting the maximum intended load and so installed as to prevent accidental displacement

- identify hazards and appropriate safety interventions in the design and review phases of construction projects

- provide fall protection measures along unguarded roof perimeters as required by 29 CFR 1926.500 (d)(1), and install permanent railings around the perimeter of the platform once construction is completed

- conduct scheduled and unscheduled safety inspections to ensure that safety procedures are being followed.

INTRODUCTION

On April 22, 1991, a 36-year-old millwright foreman died after falling 41 feet through a platform opening. On April 29, 1991, officials of the South Carolina Occupational Safety and Health Administration (OSHA), notified the Division of Safety Research (DSR) of the death, and requested technical assistance. On May 30, 1991, two DSR safety specialists and a safety engineer traveled to the incident site to conduct an investigation. The incident was reviewed with a representative from the company and with the OSHA compliance officer assigned to the case. Photographs of the incident site and a copy of the death certificate were obtained.

The company involved in this incident has been in business for 8½ years and provides various services, including crane and tractor-trailer rentals, steel erection, and equipment/machinery installation. The company employs 50 workers, including 3 millwright foremen. The company has a written safety policy, designated safety director, and a written safety program, which includes a hazard communication program. The foremen conduct monthly safety meetings, and all employees are given safe work practices handbooks at the time they are hired. The victim worked for the employer for 5 years, but had approximately 11 years’ experience as a millwright foreman.

INVESTIGATION

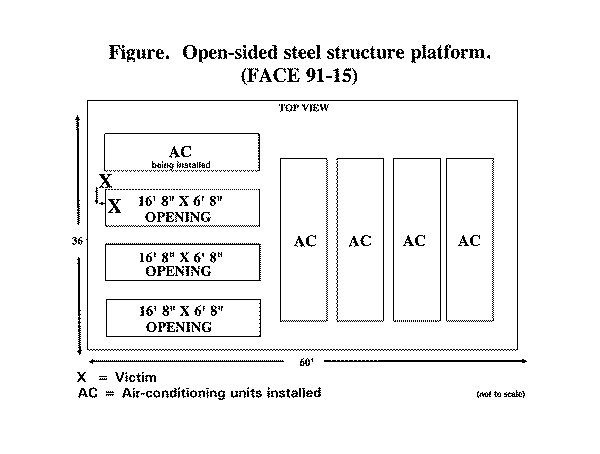

The company had been sub-contracted to erect an open-sided steel structure and platform, about 40 feet high, and to install eight air-conditioning units on top of the flat platform. The steel structure and platform had been completed and four air-conditioning units had been installed at the time of the incident. The steel-grating platform was 36 feet wide by 60 feet long with eight openings, which were each approximately 17 feet long by 7 feet wide. Air conditioning units were installed in four of the openings, and installation of the fifth air conditioner was in process (see Figure).

On the day of the incident, a crew of four workers, consisting of a millwright foreman and three millwrights-a millwright is a mechanic specializing, in the installation of heavy machinery/equipment–were continuing work to complete the installation of the air-conditioning units. The fifth air conditioner had been positioned in the opening on the platform by crane.

At the time of the incident, the crew was working on all four sides of the air conditioner, positioning shims under the unit to level it. The foreman was kneeling on the steel grating between the air conditioner and an adjacent opening. When he tried to stand up, he apparently tripped or stumbled, and fell backwards, onto the steel grating of the platform walkway. Momentum from the fall caused the victim to roll into the opening. The victim fell through the opening, struck a steel crossbeam about 20 feet below, and fell an additional 21 feet to the ground.

Two millwrights rushed to the victim, while the third millwright ran to a telephone and called the emergency medical service (EMS). The EMS arrived about 10 minutes after being contacted, stabilized the victim, and transported him to the local hospital. The victim was later transported by helicopter to another hospital where he was pronounced dead 4 hours after the incident occurred.

CAUSE OF DEATH

The death certificate listed the cause of death as severe closed head injuries.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should implement 29 CFR 1926.500 (b)(1) and 1926.500 (f)(5)(ii), which require that wherever there is danger of falling through a floor opening, it shall be guarded by a standard railing and toeboards on all exposed sides, or a cover capable of supporting the maximum intended load and so installed as to prevent accidental displacement. (1)

Discussion: The floor surface of the platform, 36 feet by 60 feet, contained eight 16-foot 8-inch long by 6-foot 8-inch wide openings. Employers should ensure that all platform openings be secured with a fixed standard railing and toeboards on all exposed sides, or a cover which would support a worker’s weight, and which would not be subject to displacement.

Note: A safety belt and lanyard was found on the platform at the incident site, but whether or not the safety equipment had been used prior to the incident could not be ascertained.

Recommendation #2: Employers should identify hazards and appropriate safety interventions in the design and review phases of construction projects.

Discussion: Worker safety requirements should be addressed and incorporated into construction project designs and working drawings during the planning phase and throughout the life of the project. Hazard control procedures specified in various working drawings point to newly created or developing hazards, and allow lead time for developing safe work practices and procedures, including training and protective equipment needs.

As review and design are ongoing processes, hazard recognition and safety intervention should also be ongoing processes.

Recommendation #3: Employers should provide fall protection measures along unguarded roof perimeters as required by 29 CFR 1926.500 (d)(1) (2), and building owners should consider installing permanent railings around the perimeter of the platform once construction is completed.

Discussion: Employers should use an appropriate fall protection system, or a combination of applicable systems (e.g., warning lines, guardrails, platforms, safety belts, nets, safety monitoring system etc.), to protect employees from falling off the edge of roofs, as required by 29 CFR 1926.500 (d)(1).

Additionally, after construction of the platform and installation of the air-conditioning units is completed, maintenance or other employees will still have foreseeable need to access the platform. The possibility of falling off the sides of the platform will still exist. Building owners should consider installing permanent railings around the perimeter of the platform to eliminate the hazard of falling off the sides of the platform once construction is completed.

Recommendation #4: Employers should conduct scheduled and unscheduled safety inspections regularly at each jobsite.

Discussion: Although the company has a written safety program which includes monthly safety meetings, scheduled and unscheduled safety inspections should be conducted on a regular basis. To be effective, a safety program must be enforced at the worksite. Regular company safety inspections demonstrate to workers that the company is committed to enforcing its safety policies and procedures.

REFERENCE

1. Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p.190 and p.193. July 1, 1990.

2. Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p.191 July 1, 1990.

image icon

image icon

Figure.

Return to In-house FACE reports