Fatigue Hazards in Seafood Processing

Fatigue Hazards in the Seafood Processing Industry

Inadequate rest and poor-quality sleep can contribute to fatigue and increased risk of occupational fatality, injury, and illness. Long shifts, or when 12-hour shifts combine with more than 40 hours of work a week, worsen workers’ physiological performance. These factors increase workers’ injury rates and illness.1

In certain regions of the United States, seafood processors may work extended hours during peak production season. Companies in Alaska’s onshore and offshore seafood processing industry report shifts of 12-18 hours, with employees often working for weeks at a time.2 Processing workers have also identified long hours, limited time for breaks, and shared sleeping arrangements as concerns.3 Interviews conducted with seafood plant managers in Alaska, representing about 68% of the Alaska seafood processing workforce, identified areas for improvement. The interview results identified long work hours and fatigue management as areas to improve health and safety.4

Solutions for this industry could include providing at least 8 hours of non-work time to allow for good sleep potential. Additionally, using fatigue risk management systems (FRMS) can help reduce the likelihood of fatigue-related fatalities, injuries, and illnesses.1, 5

Fatigue Risk Management Systems

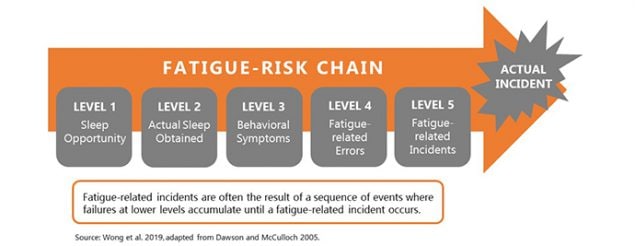

NIOSH has incorporated FRMS into recommendations for other industries including nursing and long-haul trucking. This is based on interrupting the “fatigue-risk chain” through the use of adequate sleep and training to recognize signs of fatigue before they can lead to incidents.

Workplace strategies that can be part of an FRMS include6:

- Allowing workers to have input on the design of their schedules

- Providing frequent and adequate rest breaks

- Scheduling short naps

- Breaking up monotonous tasks

- Providing training on basic sleep information, circadian rhythm, fatigue, physiology, and good sleep practices.

For information on how sleep and work schedules affect worker safety and health, and evidence-based strategies to reduce fatigue-related risks, visit NIOSH’s Center for Work and Fatigue Research page.

NIOSH

Work and Fatigue

Seminar Series

Current Research

National Safety Council

Safety Topics: Fatigueexternal icon

General Information about Sleep

CDC: Sleep and Sleep Disorders

Healthy People 2020 Sleep Healthexternal icon

National Institutes of Health, National Center on Sleep Disorders Researchexternal icon

National Institutes of Health, National Heart, Blood, and Lung Institute. Your Guide to Healthy Sleep (nih.gov)pdf iconexternal icon

American Academy of Sleep Medicine Education

Sleep Educationexternal icon

Sleep Alertness and Fatigue Education in Residencyexternal icon (SAFER Online Version)

National Sleep Foundation

National Sleep Foundationexternal icon

Shift work and sleepexternal icon

Healthy sleep tipsexternal icon

Sleep drive and your body clockexternal icon

References:

1 National Institute for Occupational Safety and Health. Overtime and extended work shifts: Recent findings on illnesses, injuries, and health behaviors. (DHHS/NIOSH Publication No. 2004-143). 2004, April.

2 Stimpfle E. Long hours on the ‘slime line’: seafood processors key to Alaska’s largest export. Alaska Econ Trends. 2012;32:10–11.

3 Garcia GM, De Castro B. Working conditions, occupational injuries, and health among Filipino fish processing workers in Dutch Harbor, Alaska. Workplace Health Saf. 2017;65(5):219–226. https://doi.org/10.1177/2165079916665396external icon.

4 Syron LN, Bovbjerg VE, Mendez-Luck CA, Kincl L [2019]. Safety and health programs in Alaska’s seafood processing industry: Interviews with safety and health managers. J Agromedicine, 24(4), 449-461. https://doi.org/10.1080/1059924X.2019.1639578external icon

5 Lerman SE, Eskin E, Flower DJ, et al. Fatigue risk management in the workplace. J Occup Environ Med. 2012;54 (2):231–258. https://doi.org/10.1097/JOM.0b013e318247a3b0external icon.

6 Caruso C. Shift work and long hours. In A. Bhattacharya & J. McGlothlin (Eds.), Occupational ergonomics: Theory and applications. Boca Raton, FL: Taylor & Francis Group; 2011. p. 451-476.