Laborer Electrocuted Upon Contacting an Energized Conveyor in Kentucky

FACE 91-22

SUMMARY

A 59-year-old male laborer (victim) was electrocuted while painting a section of support steel for a conveyor system that was being installed at an automotive parts assembly plant under construction. The victim and a co-worker were in separate single-man lifts, “touching-up” the steel with paint brushes. After lowering their lifts to get additional paint, the victim and co-worker discussed getting “minor” shocks from the conveyor. The co-worker assumed it was from nearby welders. Within minutes after the victim and co-worker resumed painting, the co-worker turned and saw the victim slumped in his lift. Once the victim was lowered to the ground by others in the area, co-workers immediately administered cardiopulmonary resuscitation (CPR). The victim was unresponsive. An emergency medical service (EMS) unit arrived within 10 minutes and transported the victim to the local hospital, where he was pronounced dead, 45 minutes after arrival. Co-workers at the scene indicated that shortly after the incident several pieces of equipment and materials were removed from the site. NIOSH investigators concluded that, in order to prevent similar occurrences, employers should:

- conduct thorough investigations when workers report electrical “bites,” “nips,” or other descriptions of mild shock, and immediately implement appropriate corrective measures

- provide effective electrical grounding of all conductive assemblies and structures during the installation of conveyor systems and ensure that this provision is addressed during the planning and design phases of all projects

- provide thorough inspections of all electrically powered tools and equipment prior to, and periodically during, their use at the worksite

- provide ground-fault circuit interrupter (GFCI) protected power circuits for all electrically powered hand tools and equipment used on construction sites

- advise employees of the shock hazard associated with touching or contacting a suspected electrocution victim

- provide, as part of the emergency response program, an assurance that injury worksites remain as undisturbed as possible to facilitate a safe, prompt incident investigation.

INTRODUCTION

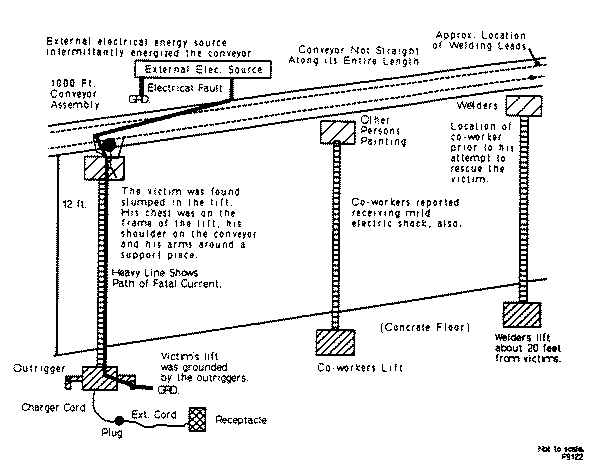

On May 31, 1991, a 59-year-old male laborer was electrocuted while painting a section of support steel for a conveyor system that was being installed at an automotive parts assembly plant under construction. Officials of the Kentucky Labor Cabinet, Division of Compliance (KYOSHA), notified the Division of Safety Research (DSR) of the fatality on July 25, 1991, and requested technical assistance. On July 29, 1991, a DSR Occupational Safety and Health Specialist, a safety engineer, and a medical officer conducted an investigation. The DSR investigators met with company officials, the coroner, and KYOSHA compliance officials. Since photographing the site was not permitted, a figure illustrating the site at the time of the incident was developed and is attached to this report.

Several subcontractors were actively installing structure and equipment inside the plant. There were 2 painters and more than 20 welders, working on the conveyor structure at the time of the incident. The company, which employed the victim, had no safety officer, but did have a brief, written safety program with job-specific safety and emergency response procedures. On-the-job safety training was provided to their employees. Toolbox meetings were routinely held on site to discuss job-specific safety practices. At the time of the electrocution, the victim was using fall protection. The victim had been employed by the company for 1½ months.

INVESTIGATION

The victim was painting a section of support steel during the construction of a 200,000-square-foot automated, conveyor-based assembly plant. The structural steel had already been erected, and fabrication work was partly completed on the assembly line conveyor. Welders continued the fabrication while painters worked alongside them, painting supports which were already in place.

At the time of the incident, the victim was painting from a battery-powered single-man lift. The batteries in the lift needed to be charged, so the lift was plugged into a receptacle through an extension cord, that did not have ground-fault circuit interruption (GFCI) capabilities. The 55-foot extension cord had the mechanical ground (third) prong removed, and had a poorly made splice 5 feet from the receptacle end. Two co-workers were in a scissors-lift, and a third co-worker was using a single-man lift within 20 feet of the victim. All were painting the same structure (Figure).

Two hours prior to the incident, the victim told the supervisor that he had been receiving shocks from the conveyor. The supervisor checked the “grounds on the welders” and both went back to work. The victim discussed the shocks with co-workers several times in the next hour, but they were dismissed as being “minor,” and probably due to “the welders.” About 1 hour after the last discussion (and several minutes prior to the incident), the victim and co-worker descended to obtain more paint and the victim again told his co-workers that he was receiving shocks; again they were dismissed as insignificant. After getting more paint, the victim and closest co-worker ascended (12 feet) in their lifts and continued painting.

At about 4:40 p.m., the victim’s son, a welder on the job, was asked by his co-worker if “something was wrong with his dad.” The victim was slumped in his lift 12 feet in the air. The son immediately ran to the lift and climbed to his father. When he touched the victim, he received a pronounced shock; when he pulled the victim away from the conveyor support, the shock abated. Since the victim was tied-off to the conveyor rail, he disconnected the safety belt, lowered the victim to floor level, and removed him from the lift.

A co-worker initiated CPR and an emergency medical service (EMS) unit was summoned. The job superintendent ushered the son away from the site and into a nearby office. The EMS unit arrived in about 12 minutes and took the victim to a local hospital. After 45 minutes in the emergency room, he was pronounced dead by the attending physician.

Co-workers at the scene indicated that shortly after the incident several pieces of equipment and materials were removed from the site.

In order to determine the source of the electrical energy, the coroner had an electrician test the lift at the incident site. With the lift properly plugged into a grounded receptacle, the electrician read approximately 55 volts between the lift’s frame and the receptacle’s mechanical ground. No voltage was measured between the conveyor rail and the mechanical ground with an employee welding on the conveyor.

Later, a manufacturer’s representative of the lift company, and a consulting engineer from the University of Kentucky came to perform comprehensive checks on the lift. NIOSH investigators also conducted tests on the lift. A thorough visual inspection revealed two areas on the outriggers that looked as though there had been electrical arcing to them. Neither the consulting engineer nor the NIOSH investigators found the lift frame to be energized when it was plugged into a receptacle. The mechanical ground of the line cord was connected to the frame of the battery charger, but not to the frame of the lift. Since the lift was electrically isolated from the battery charger, it would not have been energized even if improperly plugged into a receptacle.

NIOSH investigators conducted a visual and electrical inspection of the receptacle after it had been removed from the plant by the coroner’s electrician. A portion of the receptacle face was burned adjacent to the neutral pole. It was not known when this occurred.

NIOSH investigators also conducted a visual and electrical inspection of the extension cord thought to be used with the lift at the time of the incident. (It was uncertain which cord was the one actually being used.) The 55-foot, 3-wire cord was in generally good condition along its length. The mechanical ground prong on the plug had been removed which defeated the grounding capabilities of the cord. Reversal of the hot and neutral poles of the cord’s receptacles was possible by reversing the placement of the cord’s plug in a receptacle. There were no low resistance paths measured between any pole at the receptacle end of the cord, and any damaged area along the cord’s insulation. This indicated that an arc from the cord to a grounded object was very unlikely. Approximately 5 feet from the receptacle end was a 3-wire splice. In addition to being poorly made, the mechanical ground portion of the splice had been subsequently crushed and the bare wires exposed. The hot and neutral portions had bare wire exposed also, but the splice caps were still in place. The receptacle, extension cord and lift had all been removed from the site and tested by others before DSR personnel arrived.

NIOSH investigators concluded that the secondary source of electrical energy causing the fatality was the conveyor. (The conveyor is considered a secondary source in this case because it acted only as a conductive path for the primary source; the defective device which energized it.) No conclusive evidence was found to indicate that the receptacle, extension cord, or lift acted as a source of electrical energy in the electrocution of the laborer. Statements of the co-workers, burns on the victim’s hand, and test results substantiated this conclusion. The primary source of electrical energy which energized the conveyor could not be determined. It should be noted, however, that several welding machines, grinders, and other electrical tools were being used on or near the conveyor at the time of the incident. None of this equipment was available for testing by the NIOSH investigators.

CAUSE OF DEATH

The medical examiner listed the cause of death as electrocution.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should conduct thorough investigations when workers report electrical “bites,” “nips,” or other descriptions of mild shock, and immediately implement appropriate corrective measures.

Discussion: Any electrical shock, no matter how slight, indicates an unsafe work condition requiring immediate attention. The victim and co-workers reported receiving electrical shocks while painting on several occasions earlier in the day. No corrective action was taken to eliminate the shocks, and work continued. If causal factors cannot be immediately identified, or corrective measures immediately implemented, operations at the work area should be suspended until such factors are identified and corrected. When arc welders are being used in the area, as in this case, their proper operation and maintenance should be carefully addressed (3).

Recommendation #2: Employers should provide effective electrical grounding of all conductive assemblies and structures during the installation of a system, and ensure this provision is addressed during the planning and design phases of all projects.

Discussion: Although not always required, this is consistent with the employee protection requirements for work on power transmission lines (5). Conductive structures, such as the conveyor, will be difficult to energize when properly grounded. Although this strategy will not eliminate all shock hazards, when used in conjunction with ground-fault protection, it provides a very effective intervention that will reduce the risk of electrical injury.

Recommendation #3: Employers should provide a thorough inspection of all electrically powered tools and equipment prior to, and periodically during, their use at the worksite.

Discussion: Anytime employees indicate receiving “bites,” “nips,” or other indications of mild shock, the actions discussed in recommendation #1 should be taken immediately. Often the problem can be an electrically powered tool or extension cord. Scheduling periodic tool inspections (1) is an effective preventive measure that will identify such problems before a tool causes an injury or work suspension. Double-insulated or properly grounded hand-tools are recommended (2) for use. When splice caps (or wire nuts) are used, they should be applied as specified by the manufacturer (8).

Recommendation #4: Employers should provide ground-fault circuit interrupter protected power circuits for all electrically powered hand-tools and equipment used on construction sites.

Discussion: Although an “assured equipment grounding conductor program” is permissible by OSHA requirements (4), it is often very difficult to administer and requires significant record keeping. Ground-fault circuit interrupters (GFCI) are readily available for use in the construction industry in various configurations. Initial costs of GFCI protection will be returned through the savings in time needed for record keeping and administration of the assured grounding program. Descriptions of operation, and general applications of GFCI units are readily available (6,7).

Recommendation #5: Employers should advise employees of the shock hazard when contacting a suspected electrocution victim.

Discussion: The first co-worker to contact the victim received a pronounced shock that caused him to “jump back.” In doing so, he could have received a fatal shock himself, or an injury sustained from a subsequent fall. Employers should alert employees to this hazard through their emergency response program, or other written safety guidelines. All power sources suspected of contributing to electrical shock should be de-energized before any contact with the victim is made. If this is not possible, appropriate personal protective equipment should be used.

Recommendation #6: Employers should provide, as part of the emergency response program, an assurance that injury worksites remain as undisturbed as possible to facilitate a safe, prompt, and comprehensive incident investigation.

Discussion: The only changes made to a worksite after an injury should be those which are absolutely essential for the safe rescue and treatment of victims. Coroners generally have the authority to restrict access to a site when such an incident occurs, and they should exercise this authority to enable a thorough investigation. Inspection of the site and witness testimony indicated that materials and equipment were immediately removed from the area. This made an objective, comprehensive assessment of the incident causal factors very difficult. Changes to the incident worksite can prohibit the identification of causal factors and effective interventions.

REFERENCES

1. Office of the Federal Register: Code of Federal Regulations, Labor, Title 29, Subtitle B, Chapter XVII, Part 1926.20 (b), p. 19. July 1, 1990.

2. Office of the Federal Register: Code of Federal Regulations, Labor, Title 29, Subtitle B, Chapter XVII, Part 1926.302 (a), p. 132. July 1, 1990.

3. Office of the Federal Register: Code of Federal Regulations, Labor, Title 29, Subtitle B, Chapter XVII, Part 1926.351 (a), (b), (c), & (d), p. 137-8. July 1, 1990.

4. Office of the Federal Register: Code of Federal Regulations, Labor, Title 29, Subtitle B, Chapter XVII, Part 1926.404 (a) & (b), p. 145-6. July 1, 1990.

5. Office of the Federal Register: Code of Federal Regulations, Labor, Title 29, Subtitle B, Chapter XVII, Part 1926.954 (e) & (f), p. 315. July 1, 1990.

6. Accident Prevention Manual for Industrial Operations, Laing, P. M., edit., 9th ed, R. R. Donnelly & Sons, 1988, p. 381-384.

7. International Association of Electrical Inspectors News, International Association of Electrical Inspectors, vol. 63, no. 5, p. 29-33, September/October 1991.

8. American Electricians Handbook, W. Summers ed., 10th ed., p. 2-121, par. 189, McGraw-Hill, New York, 1981.

Figure. Conveyor Assembly, Lifts, and Worker Locations