Engineering Controls Database

Asphalt Pavement-milling – Respirable Crystalline Silica Exposure

| A variety of machinery is employed in asphalt pavement recycling, including cold-planers, heater-planers, cold-millers, and heater-scarifiers [Public Works 1995]. Cold-milling, which uses a toothed, rotating cutter drum to grind and remove the pavement to be recycled, is primarily used to remove surface deterioration on both petroleum-asphalt aggregate and Portland-cement concrete road surfaces [Public Works 1995]. Dust generated during the use of road milling machines may contain respirable crystalline silica [Linch 2002]. | |

|

Breathing dust that contains respirable crystalline silica can lead to silicosis, a deadly lung disease. No effective treatment exists for silicosis, but it can be prevented by controlling workers’ exposures to dust containing respirable crystalline silica. Exposure to respirable crystalline silica has also been linked to lung cancer, kidney disease, reduced lung function, and other disorders [NIOSH 2002]. From 2003 to 2016, the National Institute for Occupational Safety and Health (NIOSH) participated in a collaborative research project involving labor, industry, and government that led to the evaluation and implementation of engineering controls designed to reduce respirable crystalline silica exposure during asphalt pavement milling in highway construction. The collaborative research was led by the National Asphalt Pavement Association (NAPA) and includes all U.S. and foreign manufacturers of heavy construction equipment that sell pavement-milling machines to the U.S. market. In addition to NAPA and the equipment manufacturers, the Silica/Asphalt Milling Machine Partnership includes numerous paving contractors, the International Union of Operating Engineers, the Laborers International Union of North America, the Association of Equipment Manufacturers, and government organizations including the Occupational Safety and Health Administration (OSHA), the Federal Highway Administration, and the Centers for Disease Control and Prevention’s (CDC’s) National Institute for Occupational Safety and Health (NIOSH). Based on the research of the Silica/Asphalt Milling Machine Partnership, NIOSH recommends engineering controls that include ventilation controls in addition to water-sprays used to cool the cutting teeth. Milling machines that adopt this well-designed dust control approach have been shown to control worker exposures to respirable crystalline silica from asphalt milling operations during 21 days of personal breathing zone sampling at 11 different highway construction sites [NIOSH 2013a,b]. The 42 personal breathing zone air sampling results (21 days with 2 workers per day) were all below the NIOSH recommended exposure limit of 0.05 mg/m3 for respirable crystalline silica ranging from below the limit of detection up to 0.024 mg/m3 [Hammond et al. 2016]. This project demonstrated that dust emission-control systems installed on new pavement-milling machines, and operated according to the manufacturers’ recommendations, are adequate to control worker exposures below occupational exposure limits for respirable respirable crystalline silica during asphalt pavement milling. The details of the dust control systems were published by NIOSH in Best Practice Engineering Control Guidelines to Control Worker Exposure to Respirable Crystalline Silica [NIOSH 2015]. In 2014, all manufacturers that sell pavement milling machines to the US market submitted letters of commitment to the OSHA docket stating that they would begin installing the best practice dust controls on all new milling machines by January 2017 [OSHA 2014]. |

|

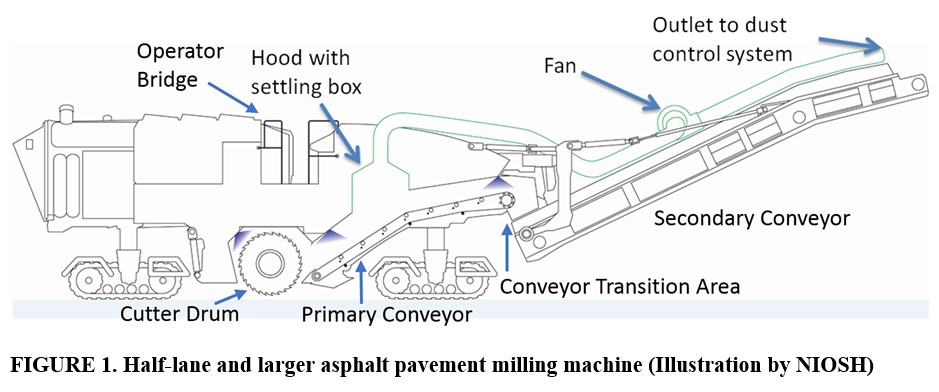

A milling machine or cold-planer is a type of highway construction machinery equipped with a toothed rotary cutter drum and conveyor system capable of rapid removal of recycled asphalt pavement. The dust control fitted to each machine is an engineering control solution that includes a combination water spray and ventilation system attached to the machine that reduces silica dust before it can reach the worker as shown in Figure 1. In this study NIOSH evaluated the effectiveness of the dust controls for all milling machine manufacturers that sold milling machines to the US market: A NIOSH document, Best Practice Engineering Control Guidelines to Control Worker Exposure to Respirable Crystalline Silica during Asphalt Pavement Milling, provides detailed recommendations for ventilation controls and water-sprays on asphalt milling machines that includes detailed engineering drawings [NIOSH 2015]. Additional information on effective dust control designs is also provided in a peer-reviewed journal article [Hammond et al. 2016]. The ventilation control recommendations provided in the NIOSH document focus on providing an enclosure around the drum housing and conveyors, proper hood and duct design, airflow capacity, durability of the duct and fan, and measures to prevent clogging of the ventilation control. To contain silica dust, the manufacturers designed their systems to remove air and maintain negative air pressure in the drum housing of the milling machine to provide containment near the source of dust generation. Milling machine manufacturers also optimized water-sprays along the primary and secondary conveyor in addition to the original water applications applied only to the drum to cool cutting teeth. The results of the study indicate that the evaluated ventilation dust controls in combination with water-sprays are capable of controlling occupational exposures to respirable crystalline silica during a wide range of typical highway construction jobs using asphalt pavement milling machines. |

|

| 282-12A; 282-14A; 282-15A; 282-16A; 282-17A; 282-18A; 282-19A; 282-20A; 282-21A; 282-22A; 282-23A; 282-24A; 282-25A; 282-26A; | |

|

Hammond DR, Stanley SA, Echt AS [2016]. Respirable crystalline silica exposures during asphalt pavement milling at eleven highway construction sites. J Occup Environ Hyg 13(7): 538-548. Linch KD [2002]. Respirable concrete dust – silicosis hazard in the construction industry. Appl Occup Environ Hyg 17(3):209–221. NIOSH [2002]. NIOSH Hazard Review: Health effects of occupational exposure to respirable crystalline silica. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2002–129. NIOSH [2013a]. Control technology for crystalline silica exposure during pavement milling using a Roadtec milling machine equipped with a local exhaust ventilation system. By Hammond DR, Shulman SA Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, EPHB Report No. 282-25a [http://www.cdc.gov/niosh/surveyreports/pdfs/282-25a.pdf]. NIOSH [2013b]. Control technology for crystalline silica exposure during pavement milling using a Wirtgen milling machine equipped with a vacuum cutting system. By Hammond DR, Shulman SA. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, EPHB Report No. 282-23a [http://www.cdc.gov/niosh/surveyreports/pdfs/282-23a.pdf]. NIOSH [2015]. Best Practice Engineering Control Guidelines to Control Worker Exposure to Respirable Crystalline Silica during Asphalt Pavement Milling. DHHS (NIOSH) Publication No. 2015–105, Cincinnati, OH: NIOSH, 2015. http://www.cdc.gov/niosh/docs/2015-105/pdfs/2015-105.pdf OSHA [2014]. Comments on the Proposed Rule — Occupational Exposure to Respirable Crystalline Silica. January 24th, 2014. Docket No. OSHA-2010-0034. Public Works [1995]. Pavement recycling. Public Works 126: April 15, 1995. |

|

| 237310 | |

|

control technology control technology crystalline silica crystalline silica pavement milling pavement milling roadtec milling machine roadtec milling machine wirtgen milling machine wirtgen milling machine |