Engineering Controls Database

Environmental Enclosures for Use in Agriculture

|

Enclosed operator cabs are employed on vehicles (e.g., tractors) to offer various levels of worker risk reduction against the hazards of the operational environment inherent in agriculture. These operations usually have physical, audible, dermal, and respiratory hazards. The cab enclosure itself is shelter against weather conditions and provides the basis for heating, ventilation, and air conditioning (HVAC) for maintaining a comfortable temperature and a breathable quantity of outside makeup air for the operator. A critical component of these enclosed cabs is their filtration systems. A fan pulls air through filters and then blows the cleaned air into the cab, pressurizing the cab. These enclosures may be used instead of respirators to protect workers from harmful particles or aerosols. Because these enclosures may be used for many years, enclosure performance may degrade due to aging and inadequate maintenance. |

|

| Agriculture is one of the most dangerous occupations in the United States. Many studies have shown workers with respiratory and musculoskeletal symptoms, hearing loss, and skin disorders in agriculture [Rautiainen and Reynolds 2002]. Agricultural workers and their families experience a disproportionate share of injuries and diseases with exposure to chemical, biological, and physical hazards [Novello 1991]. Some of these diseases include asthma, hypersensitivity pneumonitis, chronic and acute bronchitis, and organic dust syndrome. | |

|

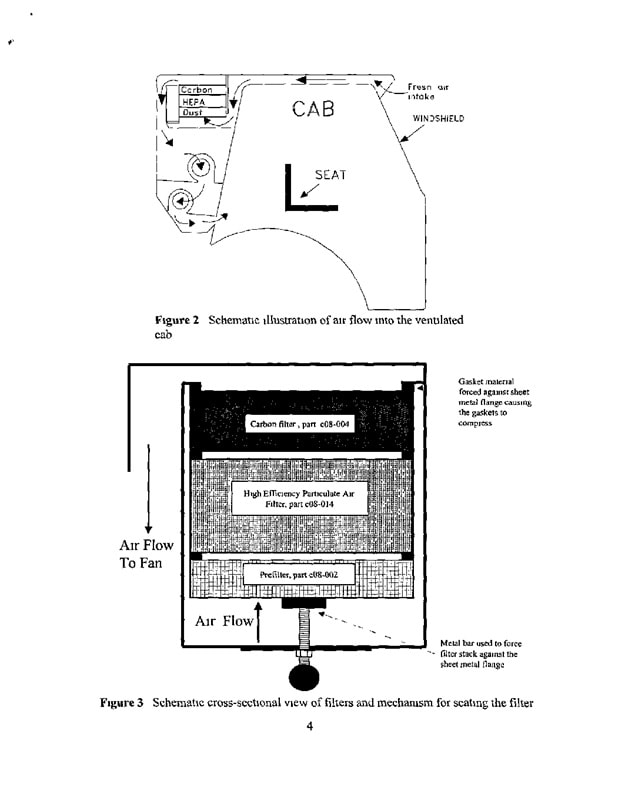

The National Institute for Occupational Safety and Health (NIOSH) conducted a study to provide information on the effectiveness of agricultural cabs [Figure 1] designed to protect agriculture workers from pesticides and other agriculture air contaminants and identify improvements to enhance the enclosure's efficacy. The main goal of the agricultural enclosures project was to evaluate the ability of enclosures on agricultural vehicles to reduce operator exposure to pesticides and other agriculture air contaminants. The major objectives for the laboratory and field evaluation were to: • evaluate the effectiveness of the filter system • identify aerosol size distribution inside and outside the enclosure • evaluate air infiltration into the cab by identifying potential leak sources • evaluate the protection factor (outside concentration/inside concentration) for agricultural cabs  Seven in-depth survey reports (including field and laboratory evaluations) were conducted by NIOSH [DPSE 1997a, DPSE 1997b, Hall et al. 1997, Hall and Heitbrink 1997, Heitbrink and Moyer 2000a, Heitbrink and Moyer 2000b, Heitbrink and Moyer 2000c] on several agricultural enclosures. Optical particle counters were used to measure the particles or aerosol concentrations inside or outside the cabs. A number of environmental enclosures were evaluated on various tractors (e.g., John Deere, Ford, Massey Ferguson, and Kubota). These environmental enclosures included cabs made by Nelson Manufacturing Co. (Nelson Spray Cab®) and John Deere (7000 and 6410 series). One field evaluation [Hall et al. 1997] was performed on a Nelson Spray Cab® designed to fit on a Massy Ferguson 396 tractor. The cab was designed to pull fresh air into the ventilation system from the front top portion of the cab. The fresh air flows through a filter system that consists of 3 separate filters. The first is a pre-filter (paper filter to remove larger particles) that is followed by a High Efficiency Particulate Air filter (HEPA filters are designed to be at least 99.97% efficient at filtering aerosol of size 0.3 µm) and an activated carbon filter. After the air passes through the filters it is then blown into the cab through louvers located behind the operator seat and maintains positive pressure inside the cab. Figures 2 and 3 are schematic views for the air flow into the cab.  |

|

| 223-11B; 223-13-A; 223-15-A; 223-16-A; 223-17-A; 223-18-A; | |

|

ASAE [1997]. American Society of Agricultural Engineers. Agricultural cabs-environmental quality. Part 1: Definitions, test methods, and safety practices. Standard S525-1. St Joseph, MI. DPSE [1998a]. Division of Physical Science and Engineering. In-depth survey report: Control technology for environmental enclosures – The effect of wind speed upon aerosol penetration into an enclosure at clean air filter. Defiance, OH. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-15a. DPSE [1998b]. Division of Physical Science and Engineering. In-depth survey report: Control technology for environmental enclosures – an evaluation of in-use enclosures at John Deere product engineering center, Waterloo, IA. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-19a. Hall RM, Heitbrink WA, McGlothlin J [1997]. In-depth survey report: Control technology for agricultural environmental enclosures at Nelson manufacturing Co., Inc. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-11b. Hall RM, Heitbrink WA [1997]. In-depth survey report: Control technology for agricultural environmental enclosures at John Deere manufacturing Co. Inc. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-13a. Heitbrink WA, Moyer E [2000a]. In-depth survey report: Control technology for environmental enclosures: an evaluation of in-use enclosures at San Joaquin helicopter company, Delano, CA. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-16a. Heitbrink WA, Moyer E [2000b]. In-depth survey report: Control technology for environmental enclosures – an evaluation of in-use enclosures at Sun Pacific, Bakersfield, CA. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-17a. Heitbrink WA, Moyer E [2000c]. In-depth survey report: Control technology for environmental enclosures – an evaluation of in-use enclosures at Nelson manufacturing Co., Yuba City, CA. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH), ECTB 223-18a. Novello, Antonia C [1991]. Papers and Proceedings, Surgeon General's Conference on Agricultural Safety and Health, A Charge to the Conference. Rautiainen RH, S. J. Reynolds SJ [2002]. Mortality and morbidity in agriculture in the United States. J Agric Safety and Hlth. 8(3): 259-276. |

|

| 115115;333111 | |

|

agricultural workers agriculture farmers farms pesticide sprayers |

|

|

The results for one survey [Hall et al. 1997] utilizing the Nelson Spray Cab® indicated that the cab is more than 99% efficient at removing aerosols larger than 3.0 µm in diameter and provides protection factors greater than 250 for particles larger than 3.0 µm. The results obtained indicate that the cab provided a mean protection factor of 16 for aerosols smaller than 1.0 µm in diameter. As the particle size decreases (?2µm), the filtration efficiency of the cab decreases, which indicates that there may be some leakage of small particles into the cab. Another survey [Hall and Heitbrink 1997] indicated that John Deere model 7000 was also 99% efficient at removing aerosols greater than 3.0 µm in diameter. Results indicate that a protection factor greater than 100 (outside/inside concentration) for particles larger than 1.41 µm during field evaluation. During the laboratory evaluation protection factors were found to be greater than 100 for particles larger than 0.75µm. As the particle size decrease (?1 µm), the efficiency of the cab starts to decrease and protection factors are less than 100. This shows that there may be some leakage of small particles into the cab. Results in another survey [Heitbrink and Moyer 2000c] indicated that filter gaskets are deforming over time and allowing leakage into the cabs. This indicates that manufacturers should implement a quality control program to ensure that all cabs provide adequate exposure reduction. In addition, the degradation of the filter gasket over time needs to be examined and minimized. Based on the NIOSH evaluation of tractor-mounted enclosures, the American Society of Agricultural Engineers (ASAE) developed ASAE S25 [ASAE 1997], which is a consensus standard for a controlling applicator exposure to pesticide spray mist. Three important specifications in this consensus standard describe these enclosures for particulate air contaminants: • The static pressure in the enclosure must be at least 6 mm of water; • The penetration (ratio of concentration inside the enclosure to concentration outside the enclosure) shall be less than 0.02 (1/50 or 2%) for particles larger than 3 µm; and • The filter efficiency shall be at least 99% for particles larger than 3 µm. |