Machine Operator Dies When Struck By Flying Wood Chipper Guard

Wisconsin Case Report 05WI059

Summary

On July 22, 2005, a 56-year-old machine operator (the victim) died after he was struck by a flying guard from a wood chipper. The victim was working alone when he shut down the chipper. The chipper was a machine used to reduce wood edging and other wood waste into wood chips. The victim shut down the chipper and the blade continued to rotate for up to thirty minutes. The victim was found by one of the sawmill partners at approximately 6:00 p.m. The partner notified Emergency Medical Services (EMS) at 6:11 p.m. They arrived at 6:17 p.m. The EMS took the victim to the hospital located 20 to 25 miles away, at 6:23 p.m. The local EMS requested a paramedic intercept with a larger, better trained and more experienced crew. The EMS arrived at the hospital at 6:46 p.m. A doctor in the hospital declared the victim dead at 6:57 p.m. The FACE investigator concluded that to help prevent similar occurrences, employers should:

- ensure that guards are properly replaced or repaired.

- ensure that rotating machine blades are stopped and hazardous energy is dissipated before blade removal begins.

- ensure that workers are trained to recognize the hazards associated with working near or around rotating chipper blades.

- implement an effective Lockout Tagout program that at a minimum, meets standards set by the Occupational Safety and Health Administration (OSHA) in General Industry Regulation 29 CFR 1910.147.

Introduction

On July 22, 2005, a 56-year-old machine operator (the victim) died after he was struck by a flying guard from a wood chipper. The FACE investigator learned about the incident from the death certificate. The FACE investigator reviewed official reports and sent a letter to the company requesting an interview. The FACE investigator followed up with a telephone call to the company and an on-site interview was arranged for July 27, 2006.

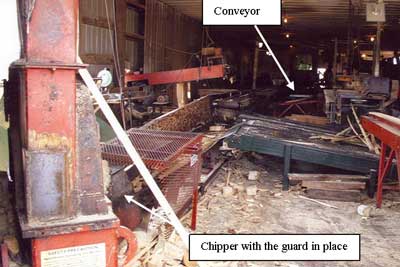

The company where the incident occurred was a saw mill. The logs were purchased by another company. This company mainly cut the logs to dimensional size lumber (i.e. 2” by 4”) in the rough. The saw mill also manufactured other wood products such as landscape timbers, fence posts, and rough sawn 8 foot boards and wood chips. The wood products were then returned to the original company for pressure treating. The waste wood was transported by a conveyor to the chipper (Figure 1) with the waste made into wood chips. The chipper was a 48” machine manufactured by Morbarb Industries Inc. of Winn, Michigan. The chipper blade was guarded by a heavy steel guard that was hinged on one side and attached to the chipper ( Figure 2). The guard weighed approximately 200 pounds. The guard protected the rotating blade from accidental contact (Figure 3).

The company consisted of twelve employees. Eleven of the employees worked in the saw mill using various saws and chippers. Some employees were trained in the use of industrial lift trucks. The employees received training in Lockout Tagout and the lift truck operators were licensed. While the company had a Lockout Tagout program, the program did not take into account the stored energy of the chipper. The chipper took up to 30 minutes to wind down once power was turned off.

|

|

Figure 1. The conveyor transports waste wood to the chipper.

|

|

|

Figure 2. Chipper with missing guard.

|

|

|

Figure 3. The detached chipper guard.

|

Back to Top

Investigation

On the day of the incident, the victim was doing his normal work duties at the saw mill. The victim was one of the previous owners of the saw mill. He had started the business in the 1970s with a partner. They (the victim and the partner) sold the company in October 1996. The victim continued to work in the saw mill for the new owner. The victim worked a 7:00 a.m. to 3:30 p.m. shift. He usually worked after the normal shift ended to prepare the chipper for the blade change. The chipper blade was changed daily by installing a newly sharpened blade the night before beginning the next day’s shift. The victim was found by a partner at 6:00 p.m.

The victim purchased the chipper used in the incident. The 48” chipper was manufactured by Morbarb Industries. The year that the machine was manufactured is unknown because the machine had no visible model or serial numbers. The chipper did not have an operator’s manual, safety manual, or maintenance manual.

The wood process was as follows: The logs were off-loaded in the saw mill yard. The logs were then transported as needed to the saw mill for debarking. The debarked logs were then cut to size by a horizontal band saw and trimmer saws. The logs were transported to the saws by use of log carriages. The waste pieces of wood were transported by a conveyor to the chipper.

The day of the incident, the victim opened the guard for the chipper blade while the chipper blade was still rotating. The guard flew off and was found 28 feet away from the chipper. The guard sat on top of the blade and was hinged to the lower guard protecting the blade. The guard hinge had been welded previously, but not adequately, and the weld had broken.

The upper hood guard struck the still rotating blade, causing it to break off at the location where it was welded. The 200-pound upper hood guard was projected away from the chipper striking the victim in the forehead and resting 28 feet away from the chipper. The chipper blades showed a gouge in the blade where the guard had struck the blade. The victim was found about seven feet away from the chipper. There were no witnesses to the incident. The chipper was not running when the victim was found. The incident occurred 2 to 2 ½ hours after the shift ended.

The Morbarb chipper had a caution sign located on the bottom which clearly stated “This machine must be locked out prior to servicing.” The chipper had a control box with an emergency stop on it, in addition to start and stop push buttons. The chipper disconnect was turned off, but not locked out. Locks and tags were available for used by the employees if needed. The chipper hood was opened on a daily basis, normally at the end of the work shift, to inspect and replace the chipper blades.

The victim was familiar with electrical systems and maintenance in the saw mill. Management had cautioned the victim, about 36 months prior to the incident, about working on the chipper with the blade still rotating.

Cause of Death

The official cause of death was cerebral contusions and lacerations caused by blunt trauma due to being struck by a metal shroud.

Recommendations/Discussion

Recommendation #1: Ensure that guards are properly repaired or replaced, as needed, before returning machines to service.

Discussion: Guards are used to protect workers from moving parts and should be inspected to identify hazards. Replacement or repair of guards should be performed in such a way that they effectively guard against injury and ensure that the guard itself does not become a hazard.

Recommendation #2: Ensure that rotating machine blades are stopped and hazardous energy is dissipated before blade removal begins.

Discussion: In this incident no lockout tagout procedures were followed. The victim shut off the power but failed to wait for the blade to stop rotating before opening the guard. According to company sources, it took, at minimum, 30 minutes after power to the chipper was turned off for all stored energy caused by blade rotation to dissipate.

Recommendation #3: Ensure that workers are trained to recognize the hazards associated with working near or around rotating chipper blades.

Discussion: In this incident, the continued rotation of the blades presented a hazard. The victim was not aware of the hazards of continued motion of the blade even though the victim had 30 years of experience. Explicitly identifying and communicating tasks of daily maintenance of the chipper blades that may expose hazardous energy must be part of a comprehensive hazardous energy control program. This training must be thorough and all-inclusive. Re-evaluation of this training should be done on a frequent basis to maintain proficiency by the workers.

Recommendation #4: Implement an effective Lockout Tagout program to identify hazards associated with rotating blades.

Discussion: A comprehensive hazardous energy control program should be implemented through a written policy and should, for example, include the following points (see entire regulation 29 CFR 1910.147 for full requirements):

- Identify and label hazardous energy sources.

- Specify procedures to de-energize, isolate, block, and/or dissipate hazardous energy.

- Establish lockout tagout procedures to secure energy control devices.

- Verify that all energy sources are de-energized before work begins.

- Inspect the repairs before the equipment is re-energized.

- Verify that all persons are clear of danger points before re-energizing the equipment.

- Design systems that make it easy to control hazardous energy.

- Train workers in all concepts of the hazardous energy control program.

- Use one lock and one key to ensure that energy sources are properly locked out.

References

- National Institute of Occupational Safety and Health: Preventing Worker Deaths from Uncontrolled Release of Electrical, Mechanical and Other Types of Hazardous Energy. (1999). Accessed July 30, 2006.

- Morbarb Industries, 8507 S. Winn Road, P.O. Box 1000, Winn, Michigan 48896, 989-866-2381.

- Code of Federal Regulations, 29 CFR 1910.147, Lockout/Tagout. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

- Code of Federal Regulations, 29 CFR 1910.212, Machine Guarding. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

- Occupational Safety and Health Administration Pamphlet: OSHA 3120 Control of Hazardous Energy. (2002). Available at https://www.osha.gov/external icon. Accessed July 30, 2006.

Wisconsin Fatality Assessment and Control Evaluation (FACE) Program

Staff members of the FACE Project of the Wisconsin Division of Public Health, Bureau of Occupational Health, conduct FACE investigations when a machine-related, youth worker, Hispanic worker, highway work-zone death, farmers with disabilities or cultural and faith-based community’s work-related fatality is reported. The goal of these investigations is to prevent fatal work injuries studying: the working environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in fatal injury and the role of management in controlling how these factors interact.

To contact Wisconsin State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.