Rigging Slinger Killed by Swinging Log in Yarding Turn

Oregon Case Report: 08OR007

Summary

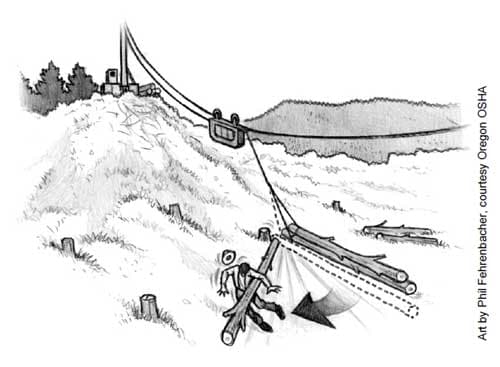

A 30-year-old logger, working as a rigging slinger in a yarding operation, was killed when he was struck by a swinging log in a moving turn. He was setting chokers out in front of the turn when the chokersetter working with him was ready to send a turn to the landing. He told the chokersetter to signal to go ahead on the turn, though he was still out front, within 15-25 feet of the turn. As the turn moved, the end of a 37-foot log dug into a bank, and swung into the air and crashed down on the rigging slinger.

|

|

The rigging slinger was not in the clear when the turn began to move, and was unable to escape a swinging log caught by an obstruction.

|

Cause of Death

Head and neck trauma

Recommendations

- Get in the clear before any lines are moved.

- Follow-up on training and supervision for safe practices, even with experienced workers.

Introduction

On March 18, 2008, a 30-year-old logger, working as a rigging slinger in a yarding operation, was killed when a log upended in a moving turn of logs and struck him. OR-FACE was notified of the incident the same day. This report is based on interviews by the OR-FACE investigator, and medical examiner and Oregon OSHA reports.

The firm was hired to perform a regeneration harvest in the Oregon Coast Range. The logging system in this operation was a standing skyline tower with a motorized carriage. Seven workers were hired to run the operation. The firm had been in the logging business for over 20 years.

The firm used a hired consultant to handle safety training, following requirements for first-aid and compliance with Oregon OSHA rules. The firm had a good track record for monthly safety meetings, training, supervisor responsibilities, emergency-response plan, and pre-unit safety meeting.

The victim in this case had over 10 years experience at logging. He was considered an experienced rigging slinger – a senior rigging slinger – with over 1½ years working for this employer. The rigging slinger is the competent person that leads the rigging crew.

Investigation

On the day of the incident, the crew started at 7 a.m., and logged for about 4 hours before the incident occurred. The rigging crew was working about 700 feet downhill from the yarder. Two workers were on the rigging. The third rigging man was at the back of the unit helping the hooktender with the next road change. The rigging slinger and a coworker, a chokersetter, took turns trading off running the whistle system to advance each turn of logs to the landing.

At the time of the incident, the crew was logging out a steep ravine that ran perpendicular to the rigging through the middle of the unit. The rigging crew was pulling the dropline off to the side of the skyline to grab the logs, and this made it necessary to hike up and out of the steep ravine to get entirely clear of each turn of logs when it moved to the landing.

The critical turn had two logs hooked. While the chokersetter pulled the hook to attach to the chokers on the logs, the rigging slinger took two chokers off the rigging to pre-set them for the next turn. After the chokersetter set the turn of logs, he proceeded to get into the clear. The rigging slinger was standing approximately 15-25 feet out in front of the turn, but told the chokersetter to sound the whistle to advance the turn to the landing. The chokersetter had a clear view of the rigging slinger.

As the turn of logs moved toward the rigging, one log dug into a bank, which upended the log and caused it to swing toward the rigging slinger. He dove between two logs on the ground for protection. The chokersetter sounded the stop whistle. The log in the air, a hemlock 37 feet long and 15 inches in diameter, crashed down on the spot where the rigging slinger huddled. The victim was pronounced dead at the scene.

Back to Top

Recommendations/Discussion

Recommendation #1. Get in the clear before any lines are moved.

The rigging slinger in this incident was not in the clear when the yarding lines began to move. Oregon OSHA regulations state that “Personnel must be in the clear of trees, logs, root wads, chunks, rolling material, all lines and rigging before any lines are moved.” (437-007-0925(5)) The definition does not give an exact definition as to what “in the clear” means; industry standards range from the distance of the longest log in the turn to twice the distance of the longest log. The employer in this instance had a standing policy that required the rigging crew to be in the clear 1½ times the distance of the longest log – over twice as far as where the rigging slinger stood. The safest location when a turn moves is behind and to the side above the turn. The steep incline at the setting may have discouraged the rigging slinger from taking the extra time and effort to reach a spot in the clear.

Recommendation #2. Follow-up on training and supervision for safe practices, even with experienced workers.

The employer in this case had a safety training program. The crew mentioned during the investigation that the topic of crowding the rigging was brought up in multiple safety meetings and the rigging slinger had been advised to avoid crowding the rigging. The experience of the coworker – the chokersetter – is not mentioned in reports, but the position is often occupied by newer workers who are trained on the job. The rigging slinger is the competent person with responsibility to make sure the rigging crew works safely.

The normal chain of command in logging has the rigging slinger answer to the hooktender, who is the foreman for operations. The hooktender then responds to the siderod or owner. The hooktender in this instance was at the back end of the unit and not present when the incident occurred.

This incident emphasizes that supervision to enforce safety rules needs to include experienced as well as new workers. Even supervisors and trainers need to have safe practices maintained and reinforced – even more so, to avoid passing on bad work habits to less experienced workers.

References

Oregon OSHA (2010). Yarding and loading handbook.pdf iconexternal icon Available online: www.orosha.org/pdf/pubs/1935.pdf

GLOSSARY

CARRIAGE: A wheeled device that rides on a skyline, used for hauling logs.

CHOKER: Length of wire rope, chain, or synthetic material with attachments for encircling a log to be yarded.

CHOKERSETTER: A member of the rigging crew who sets chokers under the direction of a rigging slinger.

DROPLINE: The length of line from the carriage to the hook or end connector that holds the choker.

HAULBACK: A line used to pull the carriage and mainline to the logs to be yarded.

HOOKTENDER: The worker that supervises the method of moving the logs from the woods to the landing.

LANDING: Any designated place where logs are laid after being yarded and are awaiting subsequent handling, loading and hauling.

RIGGING: The cables, blocks, and other equipment used in yarding and loading logs.

RIGGING CREW: Crew and equipment that pulls logs to an area called a deck or landing. From the deck, logs are loaded onto trucks for transport.

RIGGING SLINGER: The rigging slinger supervises the rigging crew – selects the logs for each turn, directs the movement of the rigging using whistles, tells the chokersetters which logs to choke, and makes sure the work area and workers are clear of hazards.

ROAD CHANGE: To move rigging and running lines to yard the next unlogged area in the felled timber.

SIDEROD: Foreman for one side; also assistant camp foreman.

SKYCAR: A motorized carriage that contains a drum of cable (dropline) that can be lowered down to the rigging crew by use of radio controls.

SKYLINE: The line hung between two or more supports on which a carriage or block travels.

STANDING SKYLINE: A standing skyline system uses a skyline, mainline, and sometimes a haulback, with a motorized carriage or skycar with a slack-pulling dropline. Lowering or raising the skyline during the cycle is not necessary.

TURN: Any log or group of logs or other material usually attached by chokers, grapples or other means and moved from a point of rest to the landing or landing chute area.

UNIT (logging): A logging site, including the workers that are rigging and yarding.

YARDER: A machine with a series of drums used to yard logs.

YARDING: Movement of logs or trees from the place where they were felled to an area where they can be further processed.

Oregon FACE Program

OR-FACE/CROET L606

Oregon Health & Science University

3181 SW Sam Jackson Park Rd.

Portland OR 97239-3098

Phone 503-494-2281

Email: orface@ohsu.edu

Website: www.ohsu.edu/xd/research/centers-institutes/croet/outreach/or-face/external icon (Link updated 8/14/2012)

Oregon Fatality Assessment and Control Evaluation (OR-FACE) is a project of the Center for Research on Occupational and Environmental Toxicology (CROET) at Oregon Health & Science University (OHSU). OR-FACE is supported by a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (2U60/OH008472-06), through the Occupational Public Health Program (OPHP), Oregon Public Health Division.

OR–FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.

To contact Oregon State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.