Fabricator Killed by Ruptured Hydraulic Press Fitting

Oregon Case Report: 04OR015

Summary

On July 14, 2004, a 20-year-old male metal fabricator was killed while setting up a 5,000 lb. hydraulic press to punch holes in metal stock to assemble cattle head gates. The fabricator was replacing the punch on the press for the current job, and placed the cylinder in its maximum return position to install the new punch. With the increase in pressure, a welded fitting attached to the hydraulic cylinder burst and impaled the fabricator near the collarbone. The victim was alone in the shop at the time of the incident, but was discovered within a half hour by his employer, lying on the floor. Medics arrived and found the victim dead at the scene.

|

|

The lower front part of the shop-fabricated hydraulic press involved in this incident shows a hole where a hose was attached to the hydraulic cylinder.

|

Recommendations

- Points of operation and all pressurized hoses should be guarded on a hydraulic press.

- Employers should ensure that all equipment is manufactured and maintained in a safe, operable condition.

- Adequate training should be provided to machine operators and fabricators, to include hazards associated with the equipment, safe operating procedures, equipment inspections, and locking out of hazardous energy sources.

Introduction

On July 14, 2004, a 20-year-old male fabricator was killed by a ruptured fitting on a 5,000 lb. hydraulic press. OR-FACE was notified of the incident on July 16, 2004. This report is based on information obtained from OR-OSHA, law enforcement, and medical examiner reports.

The employer fabricated metal livestock equipment, such as fence panels, gates, and related products. Custom work was performed upon request. Fabrication of finished product from raw metal stock involved cutting, welding, punching, grinding, assembling, and painting. Shop equipment included a variety of welders, drill presses, milling machines, lathes, chop saws, and hydraulic punches/presses. The employer had owned the business for 5-6 years as a one-man operation.

The metal fabricator involved in the fatal incident was the firm’s sole employee. He had started the job with the employer 4 months prior, worked 1 month full time before leaving for another job, and then returned a few weeks earlier to work part time.

The fabricator had limited work experience, but had worked with shop equipment, including a hydraulic press, at the shop on his family’s farm and at other jobs. He had also taken mechanical shop for 3 years in high school, which involved training in the operation of a hydraulic press. The employer stated that the fabricator was a self-starter and required very little training. He had no concerns about allowing him to work alone. The fabricator used all equipment in the shop.

Investigation

At the time of the accident, the fabricator was in the process of constructing cattle head gates, used to hold cattle while feeding in a trough. The employer had previously cut flat bar, and instructed the fabricator over the phone to punch holes in the bar as the next step. The work required the use of the hydraulic punch press and dies.

The fabricator removed the punch that had been in the press and retracted the cylinder to its maximum return position in order to install a different punch. At some point during the return stroke, the hydraulic fitting attached to the return-stroke cylinder burst and broke free from the press and its hose attachment. The return hose was attached to the cylinder 33 inches above the ground. The fabricator was evidently sitting on a rolling cart in front of the press and leaning forward, putting his upper body in direct line with the trajectory of the burst fitting. The fitting struck the victim near the collarbone, and traveled through his body to settle in his lower back without exiting. Death was probably instantaneous, according to the medical examiner.

|

|

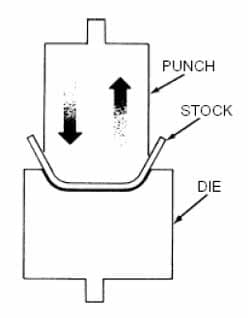

The point of operation on a power press involves forced contact of a punch onto a die in order to shape or puncture metal parts. Both punch and die may be replaced for different jobs. Source: North Carolina Division of Occupational Safety and Health (2001).

|

The hydraulic press was reportedly fabricated by the previous owner of the business, and remained in the shop on loan. The shop-fabricated press was not equipped with guards on the hose connections. The fitting for the hose on the return cylinder consisted of a 45-degree elbow screwed onto a piece of galvanized pipe, 2 in. long and 1 in. diameter. The pipe was shoved, not threaded, into the return opening, and secured with a welded flange around the outside edge. A weld on galvanized pipe tends to produce a porous, weak weld. There were no signs of failure in the weld on the outside surface, such as swelling or a leak, but failure was visible on the internal surfaces of the break. The hydraulic pressure gauge on the press was damaged and inoperable prior to the incident.

Cause of Death

Chest trauma, impalement by fitting from hydraulic press

Recommendations/Discussion

Recommendation #1: Points of operation and all pressurized hoses should be guarded on a hydraulic press.

This incident emphasizes the importance of guarding hydraulic connections.

- Hose ends must be secured to prevent whipping if an accidental cut or break occurs.

- Only standard fittings should be used on hydraulic lines.

- The rated strength of hoses, gauges, fittings, and couplings installed during machinery fabrication, as well as replacement parts, should be matched to the operating pressures of the equipment, including an appropriate safety factor.

- Hydraulic connections should be located on the side or rear of the machine, away from the operator or other workers.

Older machines commonly do not meet American National Standards Institute standards for Hydraulic Power Presses (1995, revised 2005). Retrofit packages and assorted safety devices are available from private companies to meet ANSI standards and comply with OSHA regulations. Several manufacturers produce flanges for the return-hose fitting, for example, designed to prevent the type of failure that occurred in this incident.

Recommendation #2. Employers should ensure that all equipment is manufactured and maintained in a safe, operable condition.

Attention to safety for hydraulic presses concentrates primarily on guarding against accidental contact at the point of operation, but guards and other precautions should also be maintained for hydraulic connections. Regularly scheduled inspections and preventive maintenance (monthly) needs to occur on all mechanical presses and other powered machinery. Inspections should include checking for appropriate machine guarding, wear on hydraulic hoses, operable glass-covered pressure gauges, appropriate fittings and couplings in good condition, wear or cracking of welds, and other conditions as specified in published ANSI standards. A sample inspection report is available online (see reference below).

Custom-built hydraulic presses are fairly common in small shops. Owners should ensure that unique features of their shop equipment do not compromise safety. Expert advice may be useful. The 45-degree elbow in this incident, for example, may have contributed to excessive pressure on the weld. Additionally, the press was not equipped with a bleed-off valve to regulate pressure.

Recommendation #3. Adequate training should be provided to machine operators and fabricators, to include hazards associated with the equipment, safe operating procedures, equipment inspections, and locking out of hazardous energy sources.

A hydraulic press is a hazardous machine. Operator skills should be verified through testing and periodic reviews. Oregon OSHA provides safety training and free consultation services especially designed to benefit small businesses.

References

- American National Standards Institute (2005 rev). Hydraulic power presses – Safety requirements for construction, care and use [ANSI B11.2-1995 RO5]. Order online: http://webstore.ansi.org/RecordDetail.aspx?sku=ANSI%20B11.2-1995%20(R2005) (Link updated 12/11/2007 – no longer available 8/12/2013)

- Center for Research on Occupational and Environmental Toxicology. (n.d.). Machine guarding. Online resource: http://www.croetweb.com/links.cfm?subtopicID=251external icon

- Michigan Occupational Safety and Health Administration. (2005). Mechanical power press inspection report. Includes sample inspection guide for hydraulic presses. Available online: http://www.michigan.gov/documents/cis_wsh_osc6074_125822_7.docword iconexternal icon

- North Carolina Division of Occupational Safety and Health. (2001). A guide to machine safeguarding. Available online: http://www.nclabor.com/osha/etta/indguide/ig3.pdfpdf iconexternal icon

Oregon FACE Program

CROET at OHSU performs OR-FACE investigations through a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research. The goal of these evaluations is to prevent fatal work injuries in the future by studying the work environment, the worker, the task, the tools, the fatal energy exchange, and the role of management in controlling how these factors interact.

To contact Oregon State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Oregon FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.