Sheet Metal Worker Dies After Falling 45 Feet From Air Duct

DATE: July 19, 1999

MN FACE Investigation 99MN01501

SUMMARY

A 43-year-old worker died of injuries sustained when he fell approximately 45 feet at a commercial construction site. The victim who was a member of the local sheet metal workers’ union, was employed by a mechanical company that was subcontracted on the project. On the day of the incident the victim had been installing metal air ducts. Prior to falling, the victim and two co-workers were working from a scaffold that was 45 feet above the ground. The two coworkers had been working on one end of the scaffold which was near a large vertical air duct known as a riser. For reasons that remain unclear, the victim climbed over the scaffold’s guardrail and onto a horizontal section of the air duct . The victim was not wearing or using any type of fall protection equipment. The victim fell from the air duct he had climbed onto, to the floor of the building. Emergency medical personnel were immediately called and the victim was transported to a local hospital where he died one and one-half hours later. MN FACE investigators concluded that, in order to reduce the likelihood of similar occurrences, the following guidelines should be followed:

- employers should ensure that workers always work from an approved safe work platform when working at elevation;

- employers should ensure that workers follow established safe work procedures; and

- employers should design, develop, and implement a comprehensive safety program.

INTRODUCTION

On March 17, 1999, MCE investigators were notified of a work-related fatality that occurred on March 17, 1999. An employer interview with a MN FACE investigator was conducted on May 7, 1999. During MN FACE investigations, incident information is obtained from a variety of sources such as law enforcement agencies, county coroners and medical examiners, employers, coworkers and family members.

On the day of the incident, the victim died after he fell 45 feet at a commercial construction site. The victim was part of a large construction crew that were constructing a seven story, 700,000 square foot building in a major metropolitan area. Construction of the project began at the site twenty-two months before the incident and is expected to be completed in December of 1999. The number of employees at the location where the fatality occurred was between 250 and 300. The general contractor was in charge of overall safety at the construction site while the subcontractors were in charge of safety for their own employees.

The employer was a mechanical contractor that does commercial mechanical work including plumbing, heating, air conditioning, temperature controls, and sprinkler systems as well as system service work. They had one other fatality during the past 39 years. At the time of the incident, they employed in the range of 500 or more employees [1]. The victim had been in the trade for 20 years and had been hired by the employer, off and on, at various times during the past 8 years. Currently, he had worked for the employer for the past 7 months. The employer had a comprehensive safety program and employed a full-time safety coordinator who visited the incident site approximately 3 times per month.

INVESTIGATION

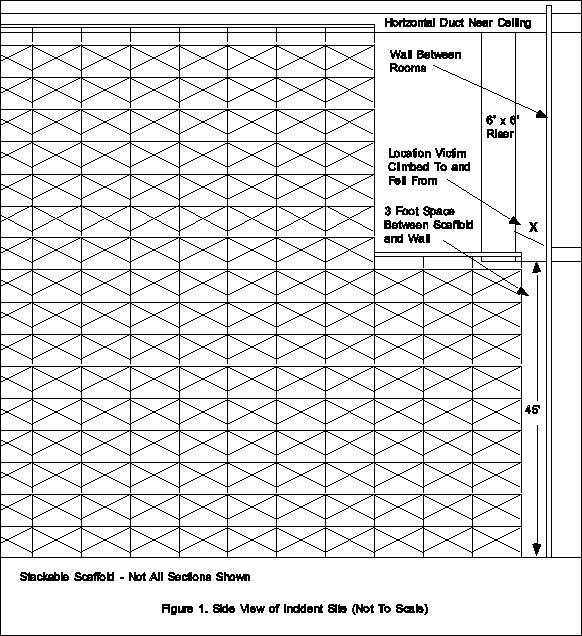

On the day of the incident, the victim and two co-workers were installing sprinklers and air ducts. They were working in a large room that measured 100 feet wide by 110 long by 90 feet high. The entire room was filled with scaffolds that consisted of individual sections of stackable steel pipe scaffold (See Figure 1). Most of the scaffolds were stacked nearly 80 feet high in order to allow workers to complete work near the top of the room. The metal scaffolds had an upper guardrail 42 inches above the platform, a mid-rail 21 inches above the platform, as well as a toeboard.

On the side of the room the victim and his two co-workers were working, there was a 3 foot space between the end of the scaffold and the wall. The scaffold they were working from was elevated 45 feet above the ground. The victim had been working on the installation of a vertical air duct, known as a riser, while one of the co-workers had also been working on duct installation and the other worker installed sprinklers. The rectangular riser measured 6 feet wide by 6 feet deep and was to be 80 feet high upon completion. The riser was installed from top (ceiling level) to bottom (ground level) and was attached to a horizontal air duct that ran across the top of the room. Upon completing the installation of a section of the riser, the scaffold was lowered 10 feet as the riser continued to be installed. At the time of the incident, approximately 35 feet of riser had been installed. The riser was also attached to a four foot section of horizontal air duct at the level the victim was working. The four foot long section overlapped one foot onto the scaffold and its upper surface sloped approximately 27 degrees toward the wall (See Figure 1). The four foot section was connected to a horizontal duct in the room adjacent to the room the workers were in. Approximately one and one-half inches of the horizontal duct extended from the wall between the two rooms. The air duct shafts in the two rooms were connected to each other and clips were installed at the seams to make the ducts more air tight.

The portion of the scaffold the victim had been working from was near the end of the scaffold closest to the three foot space near the wall. Although the victim and the two co-workers were working from the same scaffold, the riser was positioned in such a way that the co-workers were not able to see the victim and were not aware of what he was doing. The victim apparently climbed over the guardrail and pulled himself up onto the sloped portion of horizontal air duct that was connected to the air duct shaft that extended from the adjacent room. He may have intended to install the clips, on the adjoining air ducts, although this was not the standard procedure for completing the task. After climbing onto the air duct, the victim fell 45 feet down the 3 foot wide area between the scaffold and the wall. He was not wearing fall protection equipment. The two co-workers on the scaffold heard him fall and a 911 call was immediately placed. Emergency medical personnel arrived shortly after being called and transported the victim to a local hospital where he died one and one-half hours later.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that workers always work from an approved safe work platform when working at elevation.

Discussion: OSHA Standard 1926.451(g)(1) requires employers to provide protection to employees working on scaffolds elevated to more than 10 feet. The victim was working from a scaffold that was raised to 45 feet. The scaffolds that the victim had been working from had all of the required guardrails to prevent workers from falling. However, in this case, the victim climbed over the scaffold’s guardrail onto an airduct and attempted to work without using fall protection. If workers must work from unguarded surfaces, adequate fall protection equipment such as retractable lifelines, full body harnesses, and shock absorbing lanyards should always be used whenever the potential for a fall exists. If the victim had not left the scaffold or if he had worn fall protection equipment, this fatality may have been prevented.

Recommendation #2: Employers should ensure that workers follow established safe work procedures.

Discussion: In this incident, the employer’s usual procedure for the task the victim was attempting to complete was to attach a properly guarded “arm” onto the scaffold. Attaching the “arm” onto the scaffold would have allowed the worker to work from a guarded work platform while installing the clips on the 4 foot section of horizontal air duct without having to climb onto the unguarded duct. If the worker had followed the established safe work procedure for attaching the clips, this fatality may have been prevented.

Recommendation #3: Employers should design, develop, and implement a comprehensive safety program.

Discussion: Employers should ensure that all employees are trained to recognize and avoid hazardous work conditions. A comprehensive safety program should address all aspects of safety relate to specific tasks that employees are required to perform. OSHA Standard 1926.21 (b) (2) requires employers to “instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his/her work environment to control or eliminate any hazards or other exposure to illness or injury.” Safety rules, regulations, and procedures should include the recognition and elimination of hazards associated with tasks performed by employees.

REFERENCES

- Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR part 1926.451 (g)(1) U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., July 1, 1998.

- Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR part 1926.21 (b)(2) U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., July 1, 1994.

[1] The following employment ranges, 1-4, 5-19, 50-99, 100-199, 200-499, 500 or more are used to provide greater employer confidentiality.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.