Farm Hand Run Over by Tractor While Starting the Tractor While Standing On the Ground

Investigation: # 02MI140

SUMMARY

|

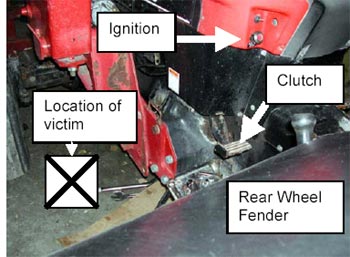

| Figure 1 – Possible position of victim |

On October 1, 2002, a 73-year old male farm hand died of injuries he sustained when he was run over by a tractor. He was starting the tractor while standing on the ground in front of one of the rear wheels. The victim had been operating the tractor earlier in the day using a front-end loader with forks to lift ½ ton fruit tanks onto a flatbed truck. After he was finished, he took the tractor to the shop. The forklift hydraulics were drifting during the loading operation and he may have been attempting to adjust the forklift position when he started the tractor. While standing on the ground in front of the rear tire, he pressed down on the clutch and started the tractor (See Figure 1). The tractor was left in gear and the tractor’s rear wheel ran over the victim, causing crushing injuries to his pelvis. He was found by another employee and taken to the hospital for surgery and stabilization. The next day, a blood clot developed and he died.

RECOMMENDATIONS

- Tractors should only be started when the operator is on the tractor platform sitting in the operator’s seat.

- Employers should provide annual operator training to tractor operators.

- A farm safety plan should be established for the agricultural operation that includes work rules such as starting the tractor from a seated position on the operator’s platform.

INTRODUCTION

On Tuesday, October 1, 2002, a 73-year old farm hand was run over by a tractor. He died the next day from his injuries. He was standing in front of a rear wheel when he started the tractor while it was in gear. On October 3, 2002, MIFACE investigators were informed by a local reporter that the individual died the previous day. On November 19, 2002, the MIFACE researchers spoke with the farm owner at the business office. The farm owner accompanied the researchers to the farm shop where the tractor was stored.

The farm owner grows grapes. The farm owner did not have a written farm safety program (written farm safety programs are voluntary). The deceased had many years experience in agriculture, having been a farm foreman, farm store owner and vineyard manager. The deceased had worked with the farm owner for at least 20 years, and was very familiar with operating tractors. The employee did not receive annual tractor operator training from the farm owner.

INVESTIGATION

|

| Figure 2 – Possible position of victim |

The victim used the tractor earlier in the day to load ½ ton cherry tanks onto a flat bed truck. The tractor was a wide front wheel configuration Case International Model 695 purchased new in the 1980s. The victim had operated this tractor many times in the past. Attached to the tractor was a front-end loader equipped with forks. The farm owner indicated that the hydraulic system of the front-end loader may have allowed the forks to drift during the cherry tank loading of the truck. The tractor had a foot-mounted clutch on the right side (when facing the front of the tractor), and the ON switch was on the left side of the tractor.

The tractor was driven to the farm shop. The shop was a pole barn with a concrete apron on the outside. The pole barn was on a hill. The tractor was on the concrete apron when the incident occurred. The deceased may have been attempting to adjust the position of the forks.

The victim placed the tractor on the apron and apparently thought he had placed the tractor in PARK. The operator did not set the brakes or chock the wheels. The tractor did not have a neutral start safety switch on the transmission that requires it to be in neutral to start the tractor or a safety switch attached to the operator seat that could shut off the tractor’s function when the operator left the seat, therefore, the tractor could start when in gear and the clutch depressed. The tractor did have a safety switch on the clutch that required the clutch to be depressed to start the tractor.

|

| Figure 3 – Final resting spot of tractor |

While standing on the ground, the victim stood in front of one of the rear wheels, depressed the clutch, and turned the ignition key to the ON position (See Figure 2). The engine started, the tractor moved forward and knocked the victim to the ground. The rear wheel ran over the victim’s pelvis. The tractor continued forward, going down a hill, crossing a street and was stopped by colliding with a truck in a valley below (See Figure 3).

A fellow employee stopped by the pole barn and heard the victim cry for help. The employee called for emergency assistance and emergency responders took the victim to the hospital. The victim went into surgery to repair his pelvis. The next day, the victim developed a blood clot that traveled to his lungs causing his death.

CAUSE OF DEATH

The cause of death as stated on the death certificate was pulmonary embolus due to a pelvic fracture from vehicular trauma. An autopsy and toxicology tests were not performed.

RECOMMENDATIONS/DISCUSSION

• Tractors should only be started when the operator is on the tractor platform sitting in the operator’s seat.

The operator’s seat of farm tractors and machines provides a workstation from which the operator can maintain proper control of the machine. When a tractor engine is started in gear, it may move suddenly and run over anything in its path. Proper control is necessary not only during operation of a tractor or machine but also whenever an engine is started. While seated in the operator’s seat an operator should check the engine throttle position, disengage the clutch and shift the transmission into neutral or park before the engine is started. Setting the brakes will prevent the tractor from rolling before the operator engages the transmission. Before starting a tractor engine, the operator should also ensure the power take off is disengaged. Performing these steps will reduce the likelihood of a tractor or machine accidentally moving forward or backward after the engine starts. In addition, if a tractor or machine does unexpectedly begin to move after starting, an operator seated in the seat will not be in danger of being run over and will be in position to maintain safe operating control.

Many modern tractor systems are equipped with additional safety interlock systems. Tractors equipped with neutral-start safety switches prevent starting the tractor engine unless the clutch pedal is depressed, the shift lever is in neutral or park or a combination of both. Some tractor models are equipped with a seat safety switch that requires the operator to be in the operator’s seat to start the tractor. When using an older model tractor without these safety interlock systems, one must be particularly careful to follow safe tractor shutdown procedures.

• Employers should provide annual operator training to tractor operators.

Michigan Occupational Safety and Health Act (MIOSHA) Part 53, Farm Field Equipment adopts the federal Occupational Safety and Health Act (OSHA) standard 1928.57 requiring annual operator training for employees operating a tractor used in agricultural operations. Appendix C of 1928.57 defines the training points to be covered by the employer. One of the training points listed in Appendix C is “when the tractor is stopped, set brakes securely and use park lock if available”. The victim did not set the brakes when he dismounted the tractor.

• A farm safety plan should be established for the agricultural operation that includes work rules, such as starting a tractor from a seated position on the operator’s platform.

There are no legal requirements in Michigan for a written safety plan in agricultural industries. We recommend a written safety plan. This plan will identify the safety and health hazards for the farm, so hazard controls can be developed. A safety plan, that is communicated to all who work on the farm will help raise awareness of safety issues, promote safe work practices, and have additional benefits of increasing work efficiency, and minimizing costs (a written safety plan may reduce worker compensation premiums). A safety plan should include work rules, such as safe tractor operation.

REFERENCES

MIOSHA Standards cited in this report can be found at the Consumer and Industry Services, Bureau of Safety and Regulation Standards Division website at http://www.michigan.gov/lara/0,4601,7-154-61256_11407_15368—,00.htmlexternal icon. (Link Updated 3/27/2013) Follow the links Workplace Safety & Health then Standards & Legislation to locate and download MIOSHA Standards.

The Standards can also be obtained for free by writing to the following address: Department of Consumer and Industry Services, MIOSHA Standards Division, P.O. Box 30643, Lansing, MI 48909-8143. MIOSHA phone number is (517) 322-1845.

- Agriculture Safety, Fundamentals of Machine Operation, 1987, John Deere & Company, Moline, Illinois, Third Edition

- MIOSHA Health and Safety Standards Agricultural Operations, Part 53, Farm Field Equipment.

MIFACE (Michigan Fatality and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 117 West Fee Hall, East Lansing, Michigan 48824-1315. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. The author of this report is working under contract to MSU and is affiliated with Wayne State University. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer. 4/28/03

To contact Michigan State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.