A 15-Year-Old Student Amputates Fingers While Operating an Unguarded Table Saw in Woodworking Class - Massachusetts

Case: 03-MA-1NF-01

Release Date: October 10, 2003

SUMMARY

In 2003, a 15-year-old student amputated one left finger (both joints) and amputated a portion of another left finger and thumb while operating an unguarded table saw in a woodworking class. The student, while making a lengthwise cut (ripping), reached around (left-hand) to the back side of the unguarded saw blade to grab the piece of wood that was being cut. The student’s fingers and thumb (left-hand) came in contact with the rotating saw blade, resulting in the serious injuries. The injured student was brought to the hallway and the school nurse was called for assistance. In addition, a call was placed to the local police department for emergency medical help. The injured student was transported to a local hospital and under went surgery for the injuries. The Massachusetts Department of Public Health concluded that to prevent similar occurrences in the future, schools that have woodworking shops with have table saws should:

- Ensure that the manufacturers’ supplied guards are installed on all table saws, and that the guards function properly and are used at all times

- Provide woodworking class conditions that at a minimum meet occupational safety and health standards set by the Occupational Safety and Health Administration (OSHA), and train students about these standards

- Position tables at the backside of table saws to prevent the work pieces from falling off the saws and onto the floor

- Design the woodworking shop layout to reduce distractions to equipment operators

INTRODUCTION

On the same day of the incident, the Massachusetts Department of Public Health (MDPH) was notified by a local police department through the 24-hour Occupational Hotline that a 15-year-old student had amputated one finger and severed others while operating a table saw in woodworking class. A call was placed to the Massachusetts Department of Education (MDOE) and a visit to the incident location was arranged. A representative from MDOE and two representatives from MDPH traveled to the school where the incident took place. The school is an educational center that serves students with behavioral and emotional needs. During this site visit, the School Director, the Education, Employment and Training Programs Director and the woodworking shop teacher were present. The police report and manufacturer information on the table saw were reviewed during the course of the investigation.

The school is designed to provide students with secondary level instruction in academic and industrial arts, such as woodworking, culinary arts, and graphic arts. The length of stay for a student can range from one month to two years and the students attending the school range in age from 13 to 22 years. At the time of the incident, the school’s enrollment was approximately 54 students.

INVESTIGATION

On the day of the incident, there were five students participating in the woodworking class, including the student involved in the incident. The school’s standard practice was to operate only one large machine in the woodworking shop at any time, excluding hand tools, given that there was only one woodworking shop teacher. The woodworking shop teacher has held this teaching position for the past six years. The school owned the table saw involved in the incident (Figure 1) when the woodworking shop teacher began working at the school.

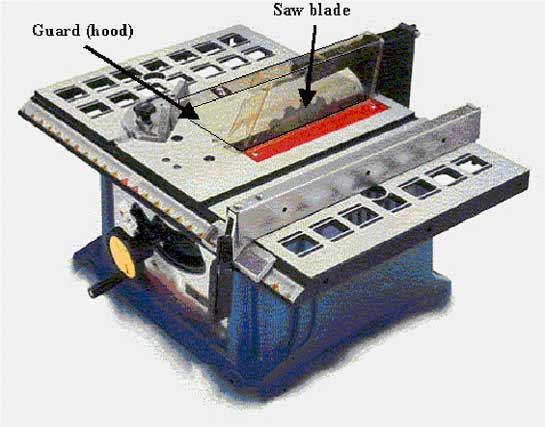

The saw, located inside the woodworking shop near the door, was a 10-inch, 115 volt, 14.2 amp, 60 hertz table saw, manufactured in 1991. The school had the manufacturer’s instruction manual for the table saw inside the woodworking shop. In addition, the school had the manufacturer supplied guard, which consisted of a hood, splitter, and anti-kick back fingers, but it was not installed on the table saw. The guard’s function is to cover the saw blade and reduce the possibility of saw operator contact with the rotating blade (Figure 2).

Students enrolled in the woodworking class spent the first several classes going through safety training. The training consisted of the shop teacher reviewing with the entire class how to operate the woodworking equipment and performing demonstrations, such as tossing a rag into the running unguarded table saw to show the students what can happen if they come in contact with the rotating saw blade. In addition, students were taught that while operating the table saw, they were prohibited from talking and other activities that could distract them.

After these initial classes, reviewing equipment operation and equipment safety, each student was required to take a test and sign a safety contract. The woodworking shop teacher then provided each student with a one-on-one demonstration on how to operate the equipment. After these one-on-one demonstrations, the students were allowed to operate the larger woodworking equipment, such as the table saw, while being supervised by the shop teacher. The shop teacher would stand within several feet of the students while they operated the woodworking equipment. During the site visit, both management and the shop teacher reported that the table saw guard was not used during training nor during operation of the saw and that the guard was stored in a closet.

The injured student was ripping a piece of wood when the incident occurred. Ripping is the operation of making a lengthwise cut through a board, typically cutting with the grain of the wood. Students were taught how to use a push stick for the ripping process. A push stick is a tool that is used to feed a piece of wood into the saw. The purpose of the push stick is to keep the operator’s hand away from the rotating saw blade. When ripping a piece of wood, a rip fence is set to the desired width and is used to position and guide the piece of wood through the saw. Students were shown that when ripping a piece of wood they must feed the entire piece of wood, using a push stick, into the saw and then let it drop onto the floor. The students were taught not to reach around to the backside of the saw to catch the ripped piece of wood after it was cut. The manufacturer’s instruction manual for the saw contained directions for safe operation including directions to keep guards in place, in working order, and to always use the guard, splitter and anti-kickback fingers on all “thru-sawing” operations.

The student who was injured had been in the woodworking class for two weeks and had accrued approximately 11½ hours (approximately 30 cuts with the saw) of supervised table saw operation. The student was working on a cutting board, and was in the process of making the cutting board legs. Prior to the incident, the student had completed a rip cut on the table saw, but the rip fence setting was incorrect. The student then readjusted the rip fence to the correct setting and with a push stick (right-hand) and the woodworking shop teacher observing, the student started to feed the piece of wood into the saw. The piece of wood that was being ripped at the time of the incident was approximately 5 inches wide, ¾ inches thick and 16 inches long. The wood piece being ripped off was ¾ inches wide and thick.

School management stated that when the student was close to finishing the second cut on the table saw another student was at the woodworking shop doorway. At this point, the woodworking shop teacher turned his attention to the student at doorway when a third student, who was inside the woodworking shop, started a conversation with the student operating the table saw. While the shop teacher’s attention was still focused at the doorway, the student operating the saw reached around to the backside of the rotating saw blade (left-hand), while still engaged in conversation, to grab the piece that was being ripped. Two left fingers and a thumb came in contact with the rotating saw blade. The left ring finger was amputated below the second joint and the left middle finger and left thumb were partially amputated at or above the first joint. In addition, the student suffered other cuts to the left hand.

The woodworking shop teacher brought the injured student out to the hallway and the school nurse was called for help. The local police were then contacted and the injured student was transported to a hospital and underwent surgery for the injuries.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Schools with woodworking shops should ensure that the manufacturers’ supplied guards are installed on all table saws, and that the guards function properly and are used at all times.

Discussion: Both the students and the teacher operated the table saw with the blade guard removed. The guard’s hood section function is to cover the saw blade and to reduce the possibility of saw operator contact with the rotating blade. If the manufacturers’ supplied guard had been installed properly this serious injury likely would have been have been prevented. When using equipment such as a table saw, it is important that the operator follows the manufacturer’s safe operating procedures. The manufacturer’s instruction manual for the saw stated that for all thru-sawing operations, which was the same type of sawing operation the student was performing at the time of the incident, guards should always be kept in place, in working order, and used.

Recommendation #2: Schools with woodworking shops should provide woodworking class conditions that at a minimum meet occupational safety and health standards set by the Occupational Safety and Health Administration (OSHA), and train students about these standards.

Discussion: Industrial Arts provides students with important opportunities to learn technical skills and introduces them to the work environment. Occupational safety and health is a crucial component of work preparation, both to ensure safety in the school shop and to develop safe work skills for the future. Schools should provide an environment that, at a minimum, meets safety and health standards set by the Occupational Safety and Health Administration (OSHA) and train students about these standards.

The OSHA standard for woodworking machinery (29 CFR 1910.213) states that ripsaws “shall be guarded by a hood which shall completely enclose that portion of the saw above the table and that portion of the saw above the material being cut”.

Recommendation #3: Schools with woodworking shops should Position tables at the backside of table saws to prevent the work pieces from falling off the saws and onto the floor.

Discussion: As recommended in the manufacturer’s instruction manual, locating a table at the rear of the saw, to be used as a work support, would prevent the work piece and the piece of wood that is being cut off the work piece from falling onto the floor. In this case, the student was reaching for the work piece, to stop it from falling onto the floor. The use of a work support table would have prevented the work piece from falling to the floor and may have prevented the student from reaching for the work piece.

Recommendation #4: Schools with woodworking shops should design the woodworking shop layout to reduce distractions to equipment operators.

Discussion: The location of the table saw near the door of the shop leading to the hallway may have increased the possibility of the operator or teacher being distracted by individuals entering, exiting or walking by the woodworking shop. The woodworking shop layout at the school involved in the incident had the table saw next to the door leading into the hallway. All of the other large woodworking equipment requiring one-on-one supervision were located at the furthest point from the woodworking shop door. Placing the table saw at the far end of the shop from the doorway and positioning it so the operator has the least amount of contact with the other students in the class could reduce the possibility of the operator or teacher being distracted while the saw was in operation.

REFERENCES

Delta International Machinery Corporation. Instruction Manual, 10-inch Contractor’s Saw. Model 34-444, 10-15-91.

Code of Massachusetts Regulations. 603 CMR 4.03. Program Approval Criteria, Vocational Technical Education.

Code of Federal Regulations. 29 CFR 1910.213. Machinery and Machine Guarding. Woodworking machinery requirements, Government Printing Office

U.S. Department of Labor, Occupational safety and Health Administration. A Guide for Protecting Workers from Woodworking Hazards. OSHA 3157. 1999.

ILO. Encyclopedia of Occupational Health and Safety, 4th Edition, Volume 3. Geneva, International Labor Office, 1998.

National Safety Council. Safeguarding Concepts Illustrated 6th Edition, 1995.

ILLUSTRATIONS

|

|

Figure 1. Table saw involved in the incident

|

|

|

Figure 2. Similar table saw with guard attached

|

To contact Massachusetts State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.