Tree trimmer falls to his death as boom truck lift arm collapses in Iowa.

SUMMARY

|

|

During February 1999, a 62-year-old self-employed tree trimmer died after falling 35 feet from the bucket of a boom truck and landing on the frozen ground. The 2-piece hydraulic lift arm was in an extended vertical position when a hydraulic safety valve on the main hydraulic cylinder snapped off, causing the lift arm to collapse and the bucket to immediately fall to the ground. The victim rode with the bucket and was thrown out of the bucket after it hit the ground. The man died shortly thereafter from hepatic rupture and internal bleeding.

RECOMMENDATIONS based on our investigation are as follows:

#1 Hydraulic fittings should be designed to withstand the stress and fatigue encountered in normal use.

#2 Engineering interventions should be developed to prevent boom lift fall in case of hydraulic failure.

INTRODUCTION

In February 1999, a 62-year-old Iowa man was killed while working as a tree trimmer. The Iowa FACE program became aware of this in December 2000, while reviewing fatality data sent from the Iowa Department of Public Health. Iowa FACE gathered additional information, and in June 2001, one investigator met with the owner of the boom truck, who was working with the victim at the time of the incident. Photographs were taken of the broken boom truck where it was stored on the owner’s property.

The owner of the boom truck normally worked as a maintenance man, and did tree work on the side, averaging 3-6 days of tree trimming work per month. The business was conducted year around, weather permitting. The victim was self-employed working part-time as a tree trimmer. He had been doing this type of tree work, and maintenance work for most of his life. A third man was usually hired, giving them a work crew of three.

There were no safety programs, nor written policies in place for this business. All three workers were handy with tools and machinery, and kept the machine in good operating condition. The men had been friends for several years, occasionally working together for tree trimming work or other odd jobs.

The victim was very experienced in the operation of this boom truck, having worked with it since 1994. They had not experienced any major problems with the boom truck, and the owner was known to take immediate action to repair any hydraulic leaks, worn hoses, etc.

INVESTIGATION

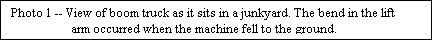

The boom truck was built in 1962, originally designed as a military de-icing unit for use at airports. It had a cage large enough for two workers, with a capacity of 320 kg (700 lbs) (see photo). It was purchased used at an auction in 1994, and was in excellent condition for its age. The previous owner was a cement ready-mix plant, which used the machine for building maintenance. All hydraulic lines on the truck were filled with automatic transmission fluid.

The boom was mounted on a double-axle straight truck. The bottom arm was 355 mm (14 in) diameter steel pipe 6.1 m (20 feet) long, and the top arm was 305 mm (12 in) diameter steel pipe 7 m (23 feet) long that tapered slightly to where the steel cage was attached. This gave the machine a vertical capacity of over 15 m (50 feet).

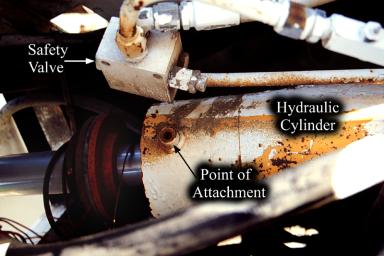

A single heavy hydraulic cylinder provided lift for each of the two lift arms. The lower, and heavier, hydraulic cylinder had a safety valve (see Photo 2) attached to the upper end of it, designed to prevent movement of any hydraulic fluid if the vehicle suddenly lost power or hydraulic pressure. This hydraulic cylinder was power-up and power-down, and was in a retracted position when the lower boom was fully raised. In Photo-1 the main hydraulic cylinder is not seen, being enclosed within the rectangular white box, which pivots on the main truck bed.

The heavy safety valve was connected with a 13 mm (½ in) threaded nipple to the top of the lower hydraulic cylinder, and had metal hydraulic tubes attached to its sides. The valve was machined out of solid steel and was approximately 75 mm (3 in) long, 63 mm (2½ in) high, and 50 mm (2 in) wide. This valve and the related fittings were protected from falling limbs due to their position under the main arm and within the steel housing around the cylinder (see Photo 1). When the lift arms are raised, the cylinder is retracted, and there is high pressure in the top portion of the cylinder.

On the day of the accident, the victim was in the elevated bucket trimming a 12 m (40 foot) tree using a small chainsaw, while his two partners were working on the ground. The truck was positioned on a city street and they were taking down a tree in a residential area. It was a rather warm day in February, with the temperature above freezing, with a slight amount of snow on the ground.

|

|

The victim was working off the back of the truck at a height of ~11 m (35 feet). They had been on the job for about 30 minutes doing routine work, tying off and cutting branches. The victim was re-positioning the boom when the safety valve suddenly snapped off where it enters the cylinder, hydraulic fluid shot out, and the elevated boom immediately fell to the ground. The victim was not handling a heavy branch or putting unusual stress on the boom at that time. A police officer at the scene, who was directing traffic, stated that he heard two pops, like something was breaking, then noticed the boom move back and forth a few times before it crashed to the ground. There was no apparent incident that could have put unusual stress on the safety valve, rather it appeared to break due to long term wear and fatigue.

|

|

The bucket, with the victim still inside, landed on the ground in the residential yard, causing a 4-inch depression in the soil. The victim was thrown out on the ground, and was noted to be breathing abnormally. He soon lost consciousness due to internal bleeding, his pulse disappeared, and he was declared dead one hour later in the hospital.

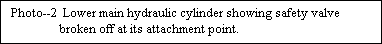

On inspection the nipple was cracked off flush with the edge of a short sleeve, welded to the side of the hydraulic cylinder (see Photo 3). The valve was hanging in position, still connected to its metal hydraulic lines (see Photo 2). The owner of the truck inspected the break and said it was a clean break, without evidence of prior cracking or rusting. He had no explanation whatsoever for what may have caused the nipple to snap, for to his knowledge, it had never been damaged prior to the accident. At the time of the inspection, the broken metal parts had rust on them.

CAUSE OF DEATH

The official cause of death taken from the death certificate is: avulsion of celiac artery from aorta, due to or consequence of: laceration of liver. An autopsy was performed, which confirmed this cause of death.

RECOMMENDATIONS / DISCUSSION

Recommendation #1 Hydraulic fittings should be designed to withstand the stress and fatigue encountered in normal use.

Discussion: This boom truck appeared to be in excellent working condition prior to the incident. There was no warning that the safety valve might break and cause the lower lift arm to fall. The exact location of the break is significant. This area, flush to the attachment point on the cylinder, implies that significant lateral stress on the safety valve was present. This type of break could occur due to metal fatigue from vibration or constant stress applied on the safety valve at this point. Considering the relative weight of the safety valve, and that the threaded nipple was its only connection to the hydraulic cylinder, it is likely that vibration over time caused metal fatigue where the nipple enters the cylinder. Anticipating such breakage through maintenance would be very difficult. There was no testing conducted on the broken metal parts, however fatigue appears the primary reason for the failure. Considering the constant stress and vibration from hydraulic fluid, as well as possible bumps from objects, it appears that the size and weight of the valve was excessive to be supported only by the 13 mm (½ in) pipefitting nipple. This size hydraulic element would likely require a fixed installation with solid brackets or other means to eliminate the vibration stress.

Recommendation #2 Engineering interventions should be developed to prevent boom lift fall in case of hydraulic failure.

Discussion: In this case, designers attached a safety valve to the cylinder, to prevent accidental lowering of the boom in case of hydraulic failure. However, there was no protection if the safety valve itself should fail. Other engineering means could be developed, such as a dual hydraulic system where one system could still work if the other system fails. Mechanical support systems may be possible as well. Relying entirely on the proper function of one hydraulic system appears to create an excessive risk in a machine such as this lift.

Fatality Assessment and Control Evaluation — FACE

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds state based programs in Alaska, California, Iowa, Kentucky, Maryland, Massachusetts, Minnesota, Missouri, Nebraska, New Jersey, Ohio, Oklahoma, Texas, Wisconsin, Washington, and Wyoming.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct in-depth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our web site listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Lois Etre, PhD, Co-Investigator; Risto Rautiainen, MS, Co-Investigator.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.