Electrical Contracting Company Line Mechanic Electrocuted After Contacting Energized Conductor While Working From an Aerial Bucket--Virginia

FACE 92-01

SUMMARY

An electrical line mechanic (the victim) was electrocuted while attempting to attach an energized conductor to a crossarm-mounted insulator. The employer had been contracted by a local electric utility to install new power poles and relocate the existing three-phase, 19,900-volt powerline onto the new poles. On the day of the incident the weather was hot and humid. An electrical line mechanic and his foreman were working from separate aerial buckets fastening the 19,900-volt conductors to insulators on opposite sides of crossarms on the new wooden power poles. When the supervisor had positioned the conductor on the insulator on his side of the crossarm, he looked down the line away from the victim to see if the conductor was clear of tree limbs or other obstructions. The supervisor saw a flash out of the corner of his eye and turned to see current arcing across a crossarm bolt in contact with the victim’s chest. The victim’s arms were in a raised position, clearly not in contact with the conductor; however, the electric current was visibly arcing across the crossarm bolt from the victim’s chest, and arcing sounds could be heard in the vicinity of the victim’s arms. Sometimes linemen raise their hands and arms to drain perspiration from their protective gloves. Droplets of moisture were later seen on the conductor, insulator, and crossarm, suggesting that the current may have tracked the perspiration into the victim’s glove, up his arm, and across his chest. The current then would have gone to ground through the cross arm bolt and down the wooden power pole, causing his electrocution. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- evaluate training and retraining programs to ensure that linemen are instructed and required to maintain the exterior surface of high voltage equipment in dry condition and to position themselves a safe distance from energized conductors before draining perspiration from their personal protective equipment (PPE)

- stress the importance of adherence to established safe work procedures, including covering conductors with insulating materials immediately upon access to the work area.

Manufacturers of PPE for linemen should:

- research and develop, if possible, more comfortable and flexible PPE.

INTRODUCTION

On September 17, 1991, an electrical line mechanic (the victim) was electrocuted while working from an aerial bucket. On September 25, 1991, officials of the Virginia Occupational Safety and Health Administration (VAOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On November 21, 1991, a DSR safety specialist traveled to the incident site to conduct an investigation. The investigator reviewed the incident with employer representatives and the county coroner. Photographs of the incident site taken immediately after the incident were viewed during the investigation.

The employer in this incident was an electrical contracting company that had been in operation for 46 years and employed 2,100 workers, including approximately 1,000 linemen. The company had a written safety policy and written safety rules and procedures which were administered by the safety director and supervisors, company owners, and jobsite foremen. The safety department was comprised of a safety director, three safety supervisors, a safety training supervisor, an equipment testing supervisor, and related clerical staff. The company maintained a video training library that covered all aspects of overhead and underground electrical power transmission and distribution. Monthly safety meetings were held and documented, and the company promoted safety through the use of safety evaluations, communications, and incentive programs. The victim had worked as a lineman for the company for 7 months, but had 31 documented years of experience as a lineman.

INVESTIGATION

The employer had been contracted by the local electric utility to install new power poles and relocate an existing three-phase, 19,900-volt (phase to ground) powerline onto these new poles, 50 feet above ground level. The new powerline was located 5 feet horizontally from the existing powerline, which was 40 feet above ground level and ran parallel to a four-lane highway.

On the day of the incident, a three-man crew consisting of a jobsite foreman, an electrical line mechanic (the victim), and a groundman were relocating and attaching existing powerline phases to crossarms on new power poles. The victim and the jobsite foreman both drove aerial bucket trucks to the worksite.

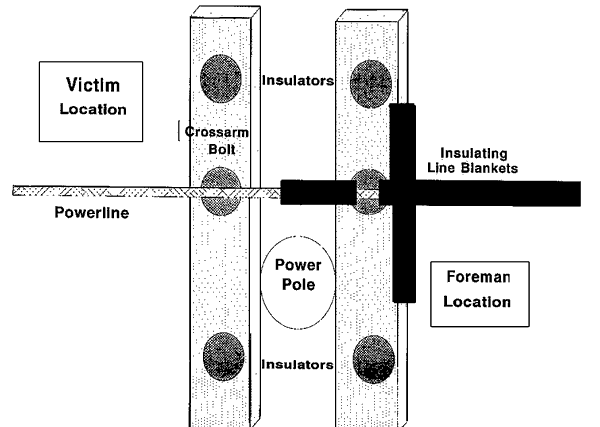

The trucks were positioned in a manner that would allow work to be performed on both sides of the crossarm. The victim and foreman could then attach the energized conductors to the insulators on their respective sides of the crossarm (Figure).

The two men raised the first conductor and positioned it on the insulators. Both men were wearing PPE (gloves and sleeves). The foreman then positioned the lip of his bucket slightly above the crossarm and covered the conductor with insulating line sleeves and the crossarm with an insulating blanket. The victim positioned the lip of his bucket below the opposite side of the crossarm. As the foreman wired the conductor to the insulator, he momentarily looked down the line, away from the victim, to see if the conductor was clear of tree limbs or other obstructions. The foreman saw a flash out of the corner of his eye and turned to see the victim slumped onto the crossarm. Although the victim’s arms were in a raised position and not in contact with the conductor, electric current could be seen arcing across a crossarm bolt in contact with the victim’s chest, and arcing sounds could be heard in the vicinity of the victim’s arms. The foreman yelled to the groundman to call the electric utility from the truck radio and tell them to summon emergency medical service (EMS). The foreman positioned his bucket under the crossarm, reached out and pushed the victim away from the crossarm, then lowered himself to the ground. After exiting his bucket, the foreman went to the victim’s truck controls and lowered him to the ground. A utility employee who heard the distress call over his radio, arrived at the scene and assisted the foreman to remove the victim from the bucket and place him on the back of the truck. The utility employee initiated cardiopulmonary resuscitation (CPR). The EMS arrived and transported the victim to the hospital where he was pronounced dead by the attending physician.

Because the temperature was 95 degrees Fahrenheit and the humidity was high, the workmen had been draining the perspiration out of their gloves every 15 to 20 minutes. The victim had not yet insulated his work area although insulating materials were present in the bucket.

It is possible that after the victim positioned the bucket, he raised his arms above his head to allow the perspiration to drain out of his gloves and sleeves. Perspiration may have contacted the energized conductor as it drained from his gloves. The current could have tracked the perspiration back into the victim’s gloves, up his arms and across his chest, exiting his chest by arcing across the crossarm bolt and then to ground through the wooden power pole. The foreman stated that there were droplets of moisture present on the conductor, the insulator, and the crossarm at the time he pushed the victim away from the crossarm.

Electrical burns were present on the victim’s chest (exit wounds), and the cross arm bolt and the crossarm were burned. The autopsy report did not identify entrance wounds.

CAUSE OF DEATH

The medical examiner listed the cause of death as electrocution.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should evaluate training and retraining programs to ensure that linemen are instructed and required to maintain the exterior surface of high voltage equipment in dry condition and to position themselves a safe distance from energized conductors before draining perspiration from their PPE.

Discussion: Because of the high temperature and humidity it was routine for the linemen to periodically drain perspiration from their PPE (gloves and sleeves) by raising their arms over their heads. In this instance, the victim did this where direct or indirect contact with an energized conductor was possible. Linemen, and others performing similar work, should be instructed to position themselves where direct or indirect contact with an energized conductor would be impossible. PPE could then be drained, removed, and wiped dry in a safe manner.

Recommendation #2: Employers should stress the importance of adherence to established safe work procedures, including covering conductors with insulating materials immediately upon access to the work area.

Discussion: Established safe work procedures required current-carrying conductors to be covered with insulating materials immediately upon access to the work area. The victim had insulating materials in his bucket but did not install them immediately after positioning the bucket. Personnel responsible for safety at the worksite should enforce company policy and ensure that established safe work procedures regarding the insulation of conductors are followed. Had the insulating material been installed, the exposure to the energized conductor would have been greatly reduced.

Recommendation #3: Manufacturers of PPE for linemen should research and develop, if possible, more comfortable and flexible PPE.

Discussion: The rubber liners and heavy, leather outer gloves worn by linemen are uncomfortably hot, heavy, and inflexible. Manufacturers of this type of equipment should research and develop, if possible and feasible, lighter, cooler and/or more flexible materials. This might alleviate problems such as perspiration, heat stress, and the lack of dexterity associated with wearing the existing PPE in hot, humid weather.

Figure.