Ironworker Dies in Ohio Following a 20-foot Fall Through a Skylight Opening

FACE 9111

SUMMARY

A 38-year-old ironworker (the victim) fell 20 feet to his death through an unguarded skylight opening. At the time of the incident, a roof had been constructed over the enclosure surrounding a new bottling operation inside an existing bottling plant. The victim and a foreman were working overtime to finish welding support hangers for the heating, ventilation, and air-conditioning (HVAC) system. The foreman was welding on the roof of the existing building (external roof), while the victim worked on the newly constructed roof (enclosure roof), about 15-20 feet directly below. The victim was apparently in the process of putting fire blankets over the existing ductwork when he either tripped and fell, or stepped, into an 18-inch by 24-inch skylight opening. The victim fell 20 feet and landed on the concrete floor, striking the back of his head. The victim was pronounced dead 2 hours later at the emergency room of a local hospital. NIOSH investigators concluded that, to prevent future similar occurrences, employers should:

- implement 29 CFR 1926.500 (b)(4) and 1926.500 (f)(6), which require that wherever there is danger of falling through a skylight opening, it shall be guarded by a fixed standard railing on all exposed sides, or a cover capable of supporting the maximum intended load and so installed as to prevent accidental displacement

- develop and/or enforce safety programs that include, but are not limited to, training and educating employees in the proper methods of covering/guarding skylight openings to prevent falls through the openings

- identify hazards and appropriate safety interventions in the design and review phases of construction projects

- provide fall protection measures along unguarded roof perimeters as required by 29 CFR 1926.500 (d)(1)

- install permanent railings around skylight perimeters or protective screens over individual skylights once construction is completed.

Additionally, property owners, prime contractors, and subcontractors should:

- ensure that areas of responsibility for safety and health issues are clearly specified as part of the contract provisions.

INTRODUCTION

On January 28, 1991, a 38-year-old ironworker died after falling 20 feet through a skylight opening. On February 19, 1991, officials of the Ohio Bureau of Workers’ Compensation, Division of Safety & Hygiene, notified the Division of Safety Research (DSR) of the death, and requested technical assistance. On March 14, 1991, a DSR safety specialist traveled to the incident site to conduct an investigation. The incident was reviewed with personnel from the Bureau of Workers’ Compensation, the employer, and the victim’s foreman. A video of the incident site and the medical examiner’s report were also obtained.

The employer involved in this incident is a metal fabrication and erection contractor which had been in operation for 18 months. The contractor employs 55 workers, including 20 ironworkers. The employer has a safety policy, designated safety officer, and a comprehensive safety program which contains specific safe job procedures. The employer provides on-the-job training, which is included in the 3-year apprentice program, and jobsite foremen conduct weekly tool box safety meetings. The victim worked for the employer for only 6 weeks, but had 20 years’ experience as an ironworker.

INVESTIGATION

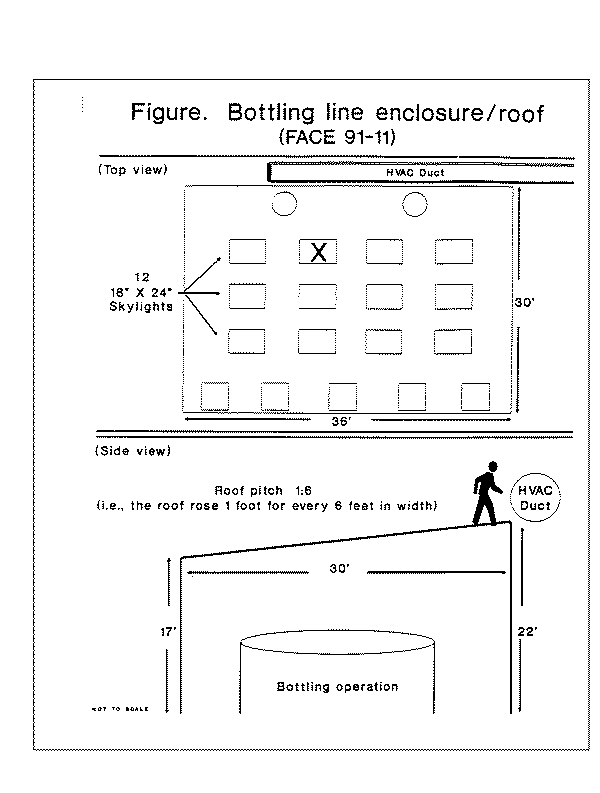

A metal fabrication and erection contractor had been selected as a subcontractor to supply and erect an enclosure around a bottling operation located inside an existing building. At the time of the incident, the enclosure’s steel skeleton and roof had been constructed. The roof frame was constructed with 3-inch angle steel, with 3-foot by 8-foot sheets of 14-gauge stainless steel welded to the frame. The roof area was 36 feet long, by 30 feet wide and contained twelve 18-inch by 24-inch skylight openings. The roof had a 1:6 pitch (i.e., the roof rose 1 foot for every 6 feet in width; see Figure).

On the day of the incident, two workers–the victim and a foreman–agreed to work overtime to finish welding support hangers for the HVAC system. About 6:45 p.m. the foreman was welding on the external roof, directly above the newly- constructed enclosure roof, attaching support hangers to the external roof’s structural steel. Previously, before the welding began, the victim had been instructed to cover ductwork located below the welding operation with fire blankets (i.e., material with the ability to withstand fire).

Although no one saw the victim fall, evidence at the site suggests that the victim was in the process of covering the ductwork with a fire blanket and either tripped on the angle iron and fell into, or stepped backwards into, a skylight opening. The victim apparently fell 20 feet and landed on the concrete floor, striking the back of his head.

The foreman, who had seen the victim 15 minutes previously, discovered the victim lying on the concrete floor. The victim was conscious, but bleeding from the ears, nose, and mouth. The emergency medical service was called and arrived about 25 minutes later. The victim was transported to the emergency room of a local hospital where he died 2 hours later.

CAUSE OF DEATH

The medical examiner’s report listed the cause of death as extensive basilar skull fracture.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should implement 29 CFR 1926.500 (b)(4) and 1926.500 (f)(6), which require that skylight openings be guarded by a fixed standard railing on all exposed sides, or a cover capable of supporting the maximum intended load, and so installed as to prevent accidental displacement.1

Discussion: The surface of the roof, 30 feet by 36 feet, contained twelve 18-inch by 24-inch skylight openings. Employers should ensure that all skylight openings be secured with a fixed standard railing on all exposed sides, or a cover which would support a worker’s weight, and which would not be subject to displacement.

Recommendation #2: Employers should develop and enforce safety programs that include, but are not limited to, reducing or eliminating worker exposures to hazardous situations.

Discussion: Employers should emphasize worker safety by implementing and enforcing existing safety programs to reduce or eliminate worker exposures to hazardous situations. Safety programs available at the time of this incident included the recognition and avoidance of fall hazards and included worker training which emphasized methods and materials for covering/guarding skylight openings to prevent falls through the openings. About 2 weeks prior to the incident, the victim attended a tool box meeting which addressed recognition and avoidance of fall hazards.

Recommendation #3: Employers should identify hazards and appropriate safety interventions in the design and review phases of construction projects.

Discussion: Worker safety requirements should be addressed and incorporated into construction project designs and working drawings during the planning phase and throughout the life of the project. Hazard identification at this preliminary stage allows lead time for training, intervention and protective equipment allocation. As review and design can be ongoing processes, hazard recognition and safety intervention can also be ongoing.

Recommendation #4: Employers should implement 29 CFR 1926.500 (d)(1), which requires that every open-sided floor or platform 6 feet or more above adjacent floor or ground level shall be guarded by a standard railing, or the equivalent.

Discussion: Employers should use an appropriate fall protection system, or a combination of applicable systems (e.g., warning lines, guardrails, platforms, safety belts, nets, safety monitoring system, etc.,), to protect employees from falling off the edge of roofs, as required by 29 CFR 1926.500 (d)(1).

Recommendation #5: Building owners should consider installing permanent railings around skylight perimeters or protective covers over individual skylights once construction is completed, to guard against falls through skylights by maintenance or other personnel who must access the roof.

Discussion: After completing construction of the enclosure, maintenance or other employees of the bottling plant will still have foreseeable needs to access the roof. The possibility of falling through a laminate covered skylight will still exist. Building owners should consider installing permanent railings around the perimeter of the skylight area, or protective screens over individual skylights, to eliminate the hazard of falling through the skylights once construction is completed.

Recommendation #6: Property owners, prime contractors, and subcontractors should ensure that areas of responsibility for safety and health issues are clearly specified as part of the contract provisions.

Discussion: Contracts between all parties (i.e., property owners, prime contractors, and subcontractors) should contain language that identifies the specific site safety and health programs to be implemented before the initiation of work. Any safety program should be consistent and compatible with the agreed upon language, and any differences should be negotiated before work begins. Where prime contractors and subcontractors are involved, the contract should contain clear and concise language as to which party is responsible for each safety and health issue. The respective parties should periodically inspect worksites to ensure that the provisions of the contract regarding safety and health issues are being upheld.

REFERENCE

1. Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. PO-13.108-Rule. July 1, 1990.

Figure.