Engineering Controls Database

Reducing Worker Exposure to Hazardous Chemicals (Including Diacetyl) During the Production and Use of Food Flavorings

| Workers exposed to flavoring chemicals in flavoring manufacturing plants, and workers exposed to flavoring chemicals in the production of different food products are at risk of developing lung disease and other health effects if their exposure is not properly controlled. Employees within the flavoring production industry have complex exposures in terms of the physical form of the agents (solid, liquid, and gas) and the number of different chemicals used. Although there are thousands of flavoring compounds in use, only a small number have occupational exposure limits. With the lack of occupational exposure limits for a majority of the thousands of flavoring chemicals, the development of exposure control guidance is critical to help reduce the risk of flavoring-related obstructive lung disease. Research by the National Institute for Occupational Safety and Health (NIOSH) has led to recommendations for preventing exposure to flavorings. | |

|

NIOSH researchers have identified bronchiolitis obliterans, a rare, respiratory disease in popcorn industry workers after exposure to diacetyl, a component of butter flavoring. Severe obstructive lung disease has also recently been documented in workers who were involved in the production of flavorings. In diacetyl-induced bronchiolitis obliterans (also known as popcorn lung), inflammation and scarring occur in the smallest airways of the lung and can lead to severe and disabling shortness of breath. Symptoms include cough (usually without phlegm) and shortness of breath on exertion. These symptoms typically do not improve when the worker goes home at the end of the workday or on weekends or vacations. Bronchiolitis obliterans can reduce lung function enough to require a lung transplant. Workers exposed to other flavorings, like 2,3-pentanedione, may also experience eye, nose, throat, and skin irritation. Worker exposure to air contaminants can best be reduced by a combination of efforts to minimize air contaminant generation through good work practices and control of the emissions at their source through process changes or engineering controls. Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective controls. |

|

|

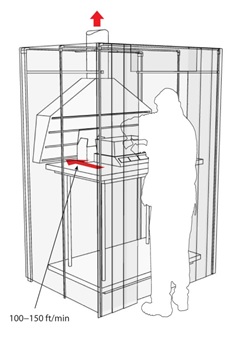

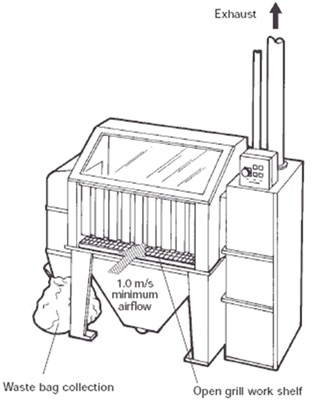

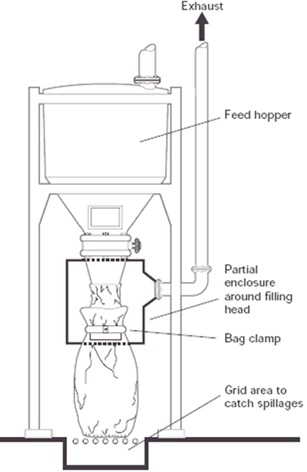

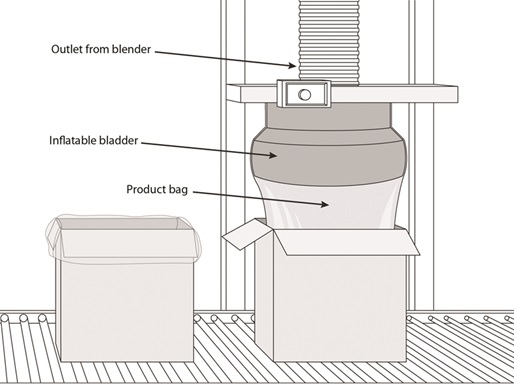

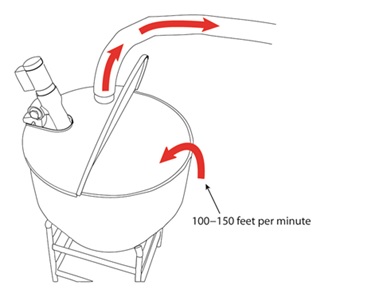

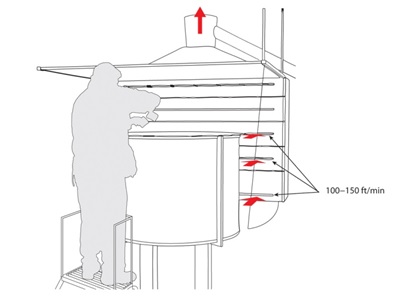

The food and flavoring production industries have several primary processes that may result in increased potential for worker exposure to diacetyl, 2,3-pentanedione, and other flavoring chemicals. These processes may be grouped, from an exposure standpoint, into a few general categories including production operations, packaging operations, cleaning, and maintenance operations. Workers in each of these job categories may potentially be exposed to flavoring chemicals, including diacetyl and 2,3-pentanedione. The following paragraphs discuss some of these common operations as well as an applicable control for reducing worker exposure. Small Scale Weighing of Materials Small-scale weighing and handling of ingredients are common tasks used in flavoring production, bakeries, dairy production, and snack food manufacturing. The tasks of weighing out both dry and wet food ingredients can lead to worker exposure primarily through the scooping, pouring, and dumping of these materials. Because weighing and pouring are often performed on a benchtop workstation, the addition of slotted backdraft ventilation for both the bench and the weighing area is recommended (Figure 1).  Bag Dumping/Emptying The opening and dumping of bags of powdered ingredients is commonly performed by workers in the production of flavorings, dairy products, snack foods, and in bakeries. Typically, a worker cuts open bags of material (e.g., 50-lb bags) and dumps the ingredients into a hopper, and then stacks or disposes of the empty bags. In powdered flavoring production, these hoppers are commonly outfitted onto blenders used to load the base starch ingredient for dry flavor blends. In snack food production, they may be used to load spices and flavors for application to the product via open drum coaters just before packaging. Technology used to control dusts during bag dumping has been in place for many years. The standard control—a ventilated bag dump station—consists of a hopper outfitted with an exhaust ventilation system to pull dusts away from workers as they open and dump bags of powdery materials (Figure 2). The designs for these devices are examples available from several sources of industrial ventilation guidance.  Bag Filling The process of filling bags with product is typically done by flavor manufacturers and other producers of powder materials. Powder flavorings are typically mixed with industrial blenders or produced by a spray drying process. For the blending process, a powdered starch or other carbohydrate is combined with a liquid or paste flavoring agent. When the blending is completed, the powder product may be discharged into a bulk tote or packaged into smaller containers. In the spray-drying process, a mixture of liquid and powder ingredients (slurry) is sprayed within a large sealed tank. Heat within the tank dries the slurry droplets, leaving a powder as the finished product. This powder is then collected and packaged in product containers. Studies conducted at flavoring production facilities have shown that intermittent peak exposures to dust and flavoring volatile ingredients occur when powder products are being packaged following blending or spray drying. The use of a ventilated collar-type hood around the discharge point can help minimize worker exposure to dust and vapors. The control includes the specification of a ventilated enclosure around the powder discharge outlet and has applicability to the filling of smaller product bags as well as intermediate bulk containers (Figure 3).  In addition to ventilation solutions, other dust control approaches have been used in a variety of industries and should be applicable for food and flavoring production. For example, an inflatable seal can be used to create a dust tight seal on the discharge outlet of an industrial blender (Figure 4). The outlet spout can be fitted with an inflatable seal that prevents dust from escaping during the bag filling process. Another system that can be used is the continuous liner system. Polypropylene liners are often used when products are discharged from the industrial blenders into the final product container. In this operation, a sleeve of polypropylene liners is stowed around the circumference of the discharge outlet. The first liner, the bottom having been sealed, is pulled down into the overpack (usually a 5-gallon bucket or a cardboard box). Product is discharged into the liner through a butterfly valve on the blender outlet. Once full, the top of the first liner sleeve is closed using tape or a fastener, or it is heat sealed and cut. The product is sealed within the poly-lined container, and a new sealed poly liner is pulled down to start discharge into the next container. This continuous process seals off the primary leak paths for dust during unloading of an industrial blender or other equipment.  Charging/filling tanks and mixers The addition of solid and liquid ingredients into tanks and other mixing vessels can cause exposure to dusts and vapors due to the displacement of air in the vessel. The use of controls to reduce worker exposure during pouring and mixing of ingredients in a commercial mixer has been evaluated in a flavoring production plant. The use of LEV at the mixing tank helps to maintain the vessel at a negative pressure and contain evaporative emissions. NIOSH evaluated the impact of a ventilated tank lid on the exposure of a worker during the mixing of a food flavoring (Figure 5). The use of the ventilated tank lid resulted in a reduction of approximately 76% compared to the same operation without the ventilated tank lid. Most of the exposure during the evaluated mixing process was attributed to tasks performed outside of the hood. Another approach evaluated by NIOSH at a flavoring manufacturing facility was the use of a ventilated mixing booth. This booth allows a large portable mixing tank to be rolled inside so that chemical vapors emitted during pouring and mixing of flavoring ingredients in the tank are captured and exhausted outdoors (Figure 6). However, the booth provides some flexibility and can also be used for other production tasks such as large pouring and product packaging activities. The use of slots across the booth plenum helps evenly distribute the flow across the height and width of the booth. A field study showed hood capture efficiencies of greater than 95% based on tracer gas tests. An important design consideration is to make the booth deep enough to fully contain the process.   Drum filling and emptying In some cases, manually operated and powered pumps have been used to transfer liquids from barrels to mixing and feed tanks. Although the use of powered pumps can reduce exposure by reducing the amount of open handling, care should be taken when filling and emptying drums of flavoring ingredients. The use of ventilation at the barrel opening has been recommended for capture of vapors during transfer of chemicals. For drum filling, an annular exhaust hood around the interface between the drum and feed pipe (at the bung hole) can be implemented (Figure 7). The recommended airflow is a minimum of 100 fpm across the drum cap/bung hole. For flammable liquids, suitable fans and equipment as well as appropriate grounding schemes should be used to prevent the buildup and discharge of static electricity. In all cases, when transferring flammable liquids, grounding and bonding requirements should be met to prevent sparks and explosions. |

|

| 322-11A; 322-12A; 322-13A; 322-14A; 322-15A; | |

|

Dunn KH [2007]. Letter of March 23, 2007, from KH Dunn, Division of Applied Research and Technology, National Institute for Occupational Safety and Health, to Kelly Howard, Department of Industrial Relations, CAL/OSHA Consultation Services. NIOSH [2004]. NIOSH Alert: preventing lung disease in workers who use or make flavorings. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2004–110. NIOSH [2008] In-depth survey report: evaluation of engineering controls for the mixing of flavoring chemicals at Gold Coast Ingredients, Inc. Commerce, CA. DHHS (NIOSH) Publication No. EPHB 322-11a. NIOSH [2008]: In-depth survey report: evaluation of engineering controls for the production of liquid and powder flavoring chemicals at Kerry Ingredients and Flavours, Inc. formerly Mastertaste, Inc., Commerce, CA. DHHS (NIOSH) Publication No. EPHB 322-12a. NIOSH [2011] In-depth survey report: Process evaluation at Baker Boy, Dickinson, ND. DHHS (NIOSH) Publication No. EPHB 322-13a. NIOSH [2012] In-depth survey report: Engineering control and process evaluation at Quaker Oats, Cedar Rapids, IA. DHHS (NIOSH) Publication No. EPHB 322-14a. NIOSH [2012] In-depth survey report: Process at Kraft Atlantic, Inc. Boston, MA. DHHS (NIOSH) Publication No. EPHB 322-15a. |

|

| 311930 | |

|

bronchiolitis obliterans bronchiolitis obliterans diacetyl diacetyl flavorings flavorings food production food production pentanedione pentanedione |

|

|

Ventilated back-draft workstations used for small batch mixing have been evaluated in two field studies conducted in flavoring production plants (Figure 1). These stations were designed to maintain an air velocity of 100–150 feet per minute (fpm) at the face of the enclosure. The field studies showed reductions in exposure of 90%–97% when performing mixing tasks using these stations. The key design parameters are to enclose as much of the activity as possible and to use properly sized exhaust slots to maintain a uniform air velocity across the face of the station. Research into the effectiveness of bag dump stations (Figure 2) has shown that they can effectively reduce worker exposure to dust and vapors. A review of commercially available units showed that their use controlled dust levels to between 1–2 mg/m3. However, dust contamination on the surface of the bag and handling/disposal of bags caused increased worker exposure. An integral pass through to a bag disposal chute/compactor will help reduce dust exposure resulting from bag handling. Further studies in mineral processing plants showed that the use of an overhead air supply also significantly decreased worker exposure. The use of controls to reduce worker exposure during pouring and mixing of ingredients in a commercial mixer has been evaluated in a flavoring production plant. NIOSH evaluated the impact of a ventilated tank lid on the exposure of a worker during the mixing of a food flavoring (Figure 5). The use of the ventilated tank lid resulted in a reduction of approximately 76% compared to the same operation without the ventilated tank lid. Most of the exposure during the evaluated mixing process was attributed to tasks performed outside of the hood. Another approach evaluated by NIOSH at a flavoring manufacturing facility was the use of a ventilated mixing booth. This booth allows a large portable mixing tank to be rolled inside so that chemical vapors emitted during pouring and mixing of flavoring ingredients in the tank are captured and exhausted outdoors (Figure 6). However, the booth provides some flexibility and can also be used for other production tasks such as large pouring and product packaging activities. The use of slots across the booth plenum helps evenly distribute the flow across the height and width of the booth. A field study showed hood capture efficiencies of greater than 95% based on tracer gas tests. An important design consideration is to make the booth deep enough to fully contain the process. |