Engineering Controls Database

Aircraft Painting Operations - Exposure Control Measures

| Refinishing of Navy aircraft is conducted at the Naval Base Coronado (NBC), San Diego, CA. During the painting operations, workers may be exposed to a number of air contaminants including hexavalent chromium (CrVI), hexamethylene diisocyanate (HDI), and methyl isobutyl ketone (MIBK). | |

|

Isocyanates are highly reactive, low molecular weight chemicals. They are the leading attributable chemical cause of occupational asthma in the United States and many other industrialized countries. Affected workers must leave their jobs to prevent progression of the symptoms. Some of these symptoms include powerful irritation to the mucous membranes of the eyes, gastrointestinal and respiratory tracts, which can lead to eye tearing, nasal congestion, dry/sore throat, cold-like symptoms, shortness of breath, wheezing and chest tightness. However, the most serious case of exposure due to chemical sensitization from the isocyanates can result in severe asthma attacks which are sometimes fatal [NIOSH 2006]. The potential health effects of exposure to other chemicals in aircraft paints include, but are not limited to, central nervous system (CNS) depression and nasal cancer. These effects are linked to various solvents [Levy and Wegman 1988] and hexavalent chromium (considered to be potential occupational carcinogens by NIOSH) [NIOSH 2009], respectively. |

|

|

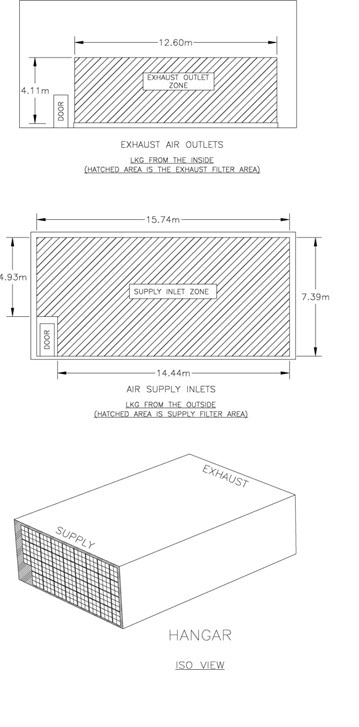

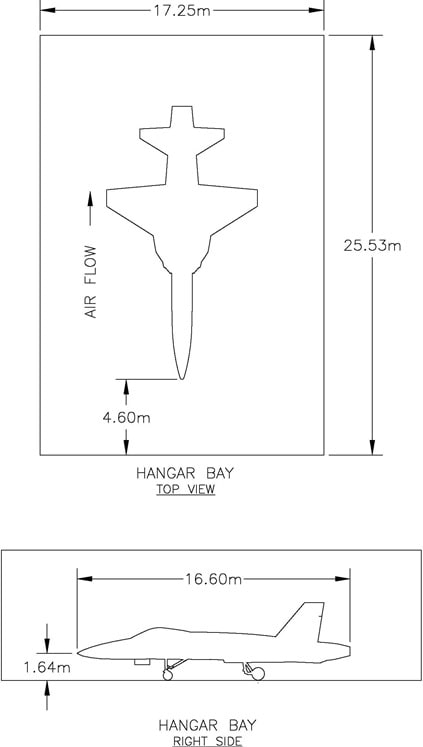

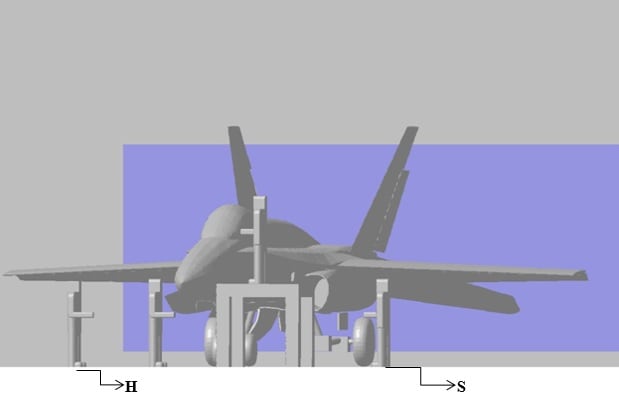

In 2008, researchers from the Centers for Disease Control and Prevention/National Institute for Occupational Safety and Health (CDC/NIOSH) began a project in collaboration with Naval Facilities Engineering Service Center (NAVFAC ESC) engineers and Navy Medical Center San Diego (NMCSD) industrial hygienists. In this project, the effectiveness and efficiency of a Navy aircraft refinishing facility ventilation system in a hangar was evaluated, alongside the appropriateness of the existing respiratory protection program. Evaluations of the hangar ventilation system were based on a combination of field studies and computational fluid dynamic (CFD) simulations. The aircraft refinishing facility is served by four supply blowers that drive ambient or heated air into a whole-wall plenum and four exhaust fans that pull contaminated air through a partial-wall plenum. Exhaust fan speed is linked to blower function via variable frequency drive (VFD) controllers. Figures 1 and 2 indicate the configuration of the bay, plenums, filters, and aircraft, with a supply wall blowing air toward an exhaust wall at the opposite end of the bay. Figure 3 shows the geometry of simulated workers, exhaust wall filter, and F/A-18C/D Aircraft. The ventilation concept is end-to-end uniform flow, where the hangar bay is essentially a very large rectangular duct.    |

|

| 329-12A; 329-12B; | |

|

Levy, B.S. and D.H. Wegman [1988]. Occupational Health; recognizing and preventing work-related disease. 2nd Ed. Boston: Little, Brown. p. 203. NIOSH [2006]. NIOSH ALERT: Preventing asthma and death from MDI exposure during spray-on truck bed liner and related applications. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2006-149. NIOSH [2009]. Hexavalent chromium. http://www.cdc.gov/niosh/topics/hexchrom]. Date accessed: December 2012. |

|

| 491110 | |

|

aircraft painting aircraft painting computational fluid dynamics computational fluid dynamics engineering controls engineering controls hexavalent chromium hexavalent chromium isocyanates isocyanates Navy aircraft Navy aircraft |

|

|

Initially, a walk-through survey was conducted encompassing range-finding air-sampling (for CrVI, HDI, and any other contaminants found on the material safety data sheets) and the gathering of hangar dimensions, geometric details, and ventilation boundary conditions that would be used to set-up the CFD simulations. Next, the current ventilation system performance in terms of contaminant control was evaluated through comprehensive air sampling of all solvent, primer, and topcoat constituents. At the same time, CFD simulations of the existing scenario were built and validated using the measurements. CFD was then used to predict concentration vs. air velocity and illustrate the relationship between volumetric flow rate of air (which has a large effect on energy use) and contaminant removal, from both health (contaminant exposure) and safety (fire and explosion) perspectives. Subsequently, a tracer gas study, with no workers present, was conducted to document the change in contaminant concentration resulting from lowering the ventilation rate under real-world conditions. The conclusions of this study led to the following recommendations: 1. The supply and exhaust airflow rates should be balanced to reduce exposure risk to workers. The balanced system should maintain the bay under slightly negative pressure (~0.1 in. water), if prevention of fugitive emissions to the environment is desired. 2. The respiratory protection program should be continued, under existing or feasibly modified ventilation. 3. Correcting the pressure imbalance should include replacing appropriate exhaust filters, pre-filters, or pre-layers during moderate or high filter loading to reduce pressure drop and save energy. The filter pressure drop value at which filters will be replaced should be recommended by NAVFAC ESC and the filter manufacturer. Balancing the system and improving system maintenance will have a marked effect on operational efficiency. 4. After balancing or any other system modifications, follow-up concentration and velocity sampling should be done to verify ventilation improvements. 5. Measurements should be made directly in the exhaust stream to demonstrate compliance with NFPA 33: “Standard for Spray Application Using Flammable or Combustible Materials 2011,” if any significant changes are made to the existing ventilation system or settings. The current study did not include this specific measurement, because area air sampling during this study clearly indicated that an explosion hazard was not present. 6. In addition to correcting existing aircraft painting facility ventilation systems, innovative design should be explored using CFD. Reducing the hangar cross-sectional area to maintain a desired velocity at a lower flow rate, directing supply air to the work zones more precisely, and bringing exhaust terminals closer to contaminant sources are examples of possible paths to consider that will reduce worker exposures, while also reducing associated energy costs. |