Engineering Controls Database

U.S. Postal Service Contaminant Controls – Automated Flat Sorter Machine

|

In 2001, terrorist attacks took place where anthrax spores were sent by mail to a U.S. Senator and to media offices [CDC 2001]. These attacks resulted in exposure to anthrax spores by postal employees working in a mail processing facility that serves the U.S. Capitol and resulted in inhalation disease in several of the workers [Mayer et al. 2001]. One potential area of exposure in the United States Postal Service (USPS) is the automated mail processing equipment used to sort incoming mail. As the mail passes through the machinery, it is compressed and impacted in a number of places that could cause release of substances from the mail. |

|

| Bacillus anthracis is a large spore forming bacteria. In the vegetative state, it is rod shaped and ranges in size from 1-1.5 X 3-10 µm. The anthrax spores are typically in the 1-5 µm size range and can enter the body by being inhaled, through the skin, or through ingestion. Disease occurs when spores enter the body, germinate, and multiply. The cutaneous form of the disease generally develops 2-5 days following exposure and can usually be successfully treated with antibiotics. The onset for the inhalation form is typically l-6 days after exposure. The inhalation form generally has a high fatality rate even with appropriate treatment [Pile et al. 1998]. | |

|

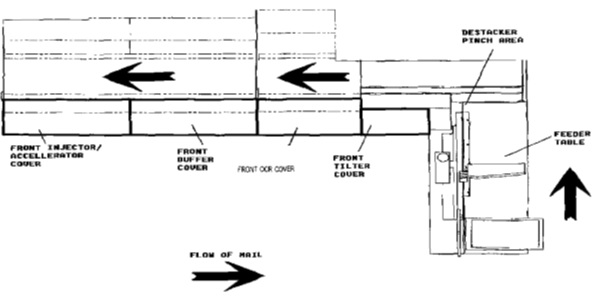

Researchers from the National Institute for Occupational Safety and Health (NIOSH) were requested to assist the USPS in the evaluation of particulate controls for various mail processing equipment. These new controls are being installed to reduce operator exposure to any potentially hazardous contaminants emitted from letter mail during normal mail processing. This effort is driven by the terrorist attacks which used the mail as a delivery system for anthrax. NIOSH researchers conducted evaluations of an exhaust ventilation system developed for the Automated Flat Sorting Machine (AFSM) 100 (Figure 1). This system was installed by the machine’s manufacturer to reduce the potential employee exposure to harmful substances that could be contained in mail processed by the machine.  Three automated feeders supply flat mail pieces. Once in the transport system, the image of each individual piece is captured. An optical character reader (OCR) reads any barcodes and the content of the address. The mail pieces are then injected into one of 759 pockets that circulate around the machine. If the correct Z1P code is determined, the mail piece is released into one of the 120 sort bins. If the address on the mail piece cannot be read by the OCR, the image of that piece is sent to a Video Coding Room in the facility. The AFSM 100 consists of a number of modules, the modules significant to the control of a potential contaminant in the mail include the feeder module, the Tilter module, the OCR module, and the interface 950 module It is in these parts of the system that the mail pieces undergo the most violent actions as they are loaded onto the machine and fed through the machine by rollers that pinch the mail. Also, at the feeder module, the mail pieces are near the worker and have the potential to release a contaminant into the worker's breathing zone. The evaluated control was retrofitted for the AFSM by the manufacturer. The control is designed to reduce emission of bacterial contaminants such as spores of B. anthracis into the ambient atmosphere through use of particle collection capabilities and filtration units. By taking advantage of the enclosed Tilter, OCR and Interface 950 Modules on the AFSM, the interior of the machine was ventilated by adding exhaust to the machine cabinet. Inside the cabinet, air intakes were placed along the path taken by the mail pieces to collect any contaminant potentially in the mail. These intakes focused on the areas around pinch points as these have the highest potential for releasing a substance. The feed table of the AFSM was also controlled by intakes located perpendicular to the feed belt and above the mail pieces. |

|

| 279-12A; 279-15A; | |

|

CDC (Centers for Disease Control and Prevention) [2001]. Investigation of bioterrorism-related anthrax and interim guidelines for exposure management and antimicrobial therapy. MMWR 50:909-919. Mayer TA, Bersoff-Matcha S, Murphy C, Earls J, Harper S, Pauze D, Nguyen M, Rosentahal J, Cerva D, Druckenbrod G, Hanfling D, Fatteh N, Napoli A, Nayyar A, Berman EL [2001]. Clinical presentation of inhalation anthrax following bioterrorism exposure. JAMA 286(20): 2549-2553. Pile JC, Malone JD, Eitzen EM, Friedlander AM [1998]. Anthrax as a potential biological warfare agent. Arch Intern Med 158:429-434. |

|

| 333318 | |

|

advanced flat sorter machine advanced flat sorter machine anthrax anthrax engineering control engineering control mail handlers mail handlers United States Postal Service United States Postal Service |

|

|

Evaluations were based on a variety of tests including tracer gas experiments, air velocity measurements, smoke release observations, and particle count experiments. The experiments showed that, overall, there is good capture by the exhaust ventilation system. Tracer gas tests indicated that the capture was essentially 100% between the feed table and the bucket insertion point. The exhaust ventilation system also exhibited good capture characteristics based on smoke release experiments and air velocity measurements. Based on these results and others discussed in the reports, the following recommendations were implemented: • Consider adding a ventilated partial enclosure at the point where the mail pieces enter the moving buckets to reduce the potential for contaminant release; • Seal cooling fan openings for fans that have been disconnected. These openings allow for the potential release of a substance that has been captured; • Ensure that the Ventilation/Filtration System (VFS) exhaust is vented to the ambient air outside of the plant if possible; • Establish a routine preventive maintenance plan; and • Consider more thoroughly evaluating the capabilities of the exhaust system with additional smoke and tracer gas testing, particularly after changes are made to the ventilation and filtration system. |