Steel Worker Falls 28 Feet To The Ground From Warehouse Construction Site

Minnesota FACE Investigation 95MN06601

SUMMARY

The victim was working for a construction company at a warehouse site at the time that the incident occurred. The construction company had been subcontracted to erect the steel framework for a 100,000-square-foot warehouse manufacturing facility. The warehouse frame was constructed mainly of vertical steel columns, horizontal “I” beams, and bar joists. On the day of the incident, the victim was “shaking out bridging.” The activity involved the distribution of 20 foot long metal pieces. After the bridging was distributed it was to be welded to the bar joists to keep them secured in place. At the time of the incident, columns which supported “I” beams and bar joists were positioned along the warehouse frame. The victim was working on top of the “I” beams and bar joists at an elevation of 28 feet. Witnesses reported that prior to falling, the victim had been wearing a body harness attached to a lanyard and a lifeline. The lifeline was secured to the structural steel. While the victim distributed the bridging, he fell from his position on the “I” beam where he was working. It is unknown why the victim was not attached to the lifeline at the time of the fall. Emergency medical personnel were called and the victim was transported to a hospital where he died thirteen days later. MN FACE investigators concluded that to reduce the likelihood of similar occurrences, the following guidelines should be followed:

- whenever any work is performed at an elevation where the potential for a serious or fatal fall exists, the employer should ensure that fall protection equipment is provided and used by all employees; and

- employers should design, develop, and implement a comprehensive safety program.

INTRODUCTION

MN FACE investigators were notified on November 16, 1995 of a work-related construction incident which occurred on November 2, 1995. The victim sustained multiple injuries including closed head trauma and died 13 days later on November 15, 1995. A site investigation was conducted by MN FACE investigators on December 18, 1995. During the site investigation, information concerning the incident was provided by the senior superintendent of the general contracting company in charge of the project. The victim’s employer, who was a subcontractor for the general contractor, was interviewed by MN FACE investigators on December 18, 1995.

The employer in this incident was a steel erector and metal fabrication company that had been in business for 27 years. The company employed about 20 workers and safety responsibilities were assigned to two foremen. The foremen were responsible for making sure that employees were provided with fall protection equipment and for the repair of all safety equipment. The employer did not have a formal training program, but hired only journeyman ironworkers who all had previous experience. Ten employees were present at the incident site at the time of the incident. The victim had worked for the employer for five years and at the incident site for one hour.

INVESTIGATION

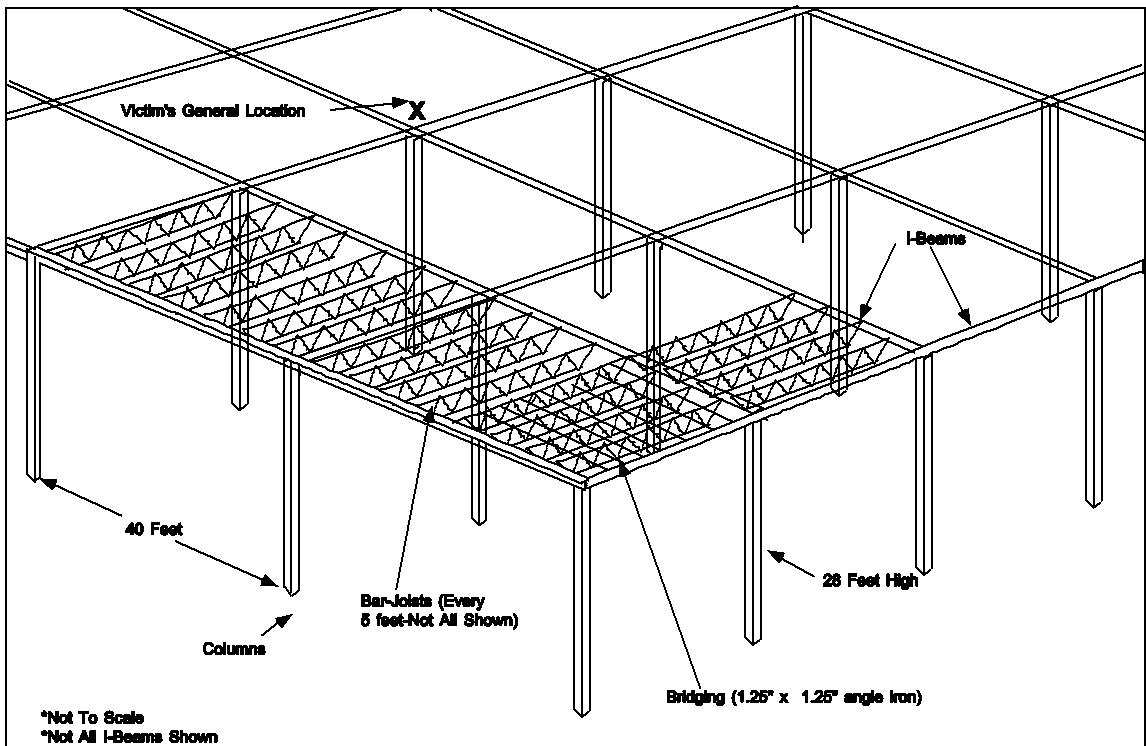

The construction company had been subcontracted to erect the steel framework for a 100,000 square-foot warehouse manufacturing facility. The warehouse frame consisted of vertical steel columns measuring 28 feet tall, horizontal “I” beams, and bar joists to support the roof. Prior to the incident, the vertical steel columns which supported the “I” beams and bar joists had been erected. The vertical steel columns were positioned 40 feet apart along the length and width of the warehouse which measured 280 by 360 feet. All of the “I” beams were in place as well as the bar joists (Figure 1).

Winds of 15 mph may have contributed to the incident. Other weather conditions that day were clouds and snow flurries. The surface on which the victim was working was dry. Witnesses reported that, prior to falling, the victim had been wearing personal protective equipment consisting of a body harness and lanyard attached to a 280 foot long horizontal lifeline. The horizontal lifeline was connected to anchors at both ends of the building as well as every forty feet along the structural steel. The purpose of anchoring the lifeline every forty feet was to shorten the distance a worker would fall.

On the day of the incident, the victim was working on top of the “I” beams at an elevation of 28 feet “shaking out bridging”. The activity involved the distribution of 20 foot long metal pieces with a width of 1.25 inches by 1.25 inches. After the bridging was distributed it was to be welded to the bar joists to keep them secured in place. Prior to distribution of the bridging, a crane was used to place bundles of it at various locations on the bar joists. While the victim distributed the bridging, he fell from his position on the “I” beam where he was working. Coworkers immediately noticed the victim after he fell and placed a call to emergency medical personnel. The victim was transported to a hospital where he died two weeks later.

Since no other workers were in the immediate work area of the victim, it could not be determined why his lanyard became disconnected from the lifeline. An inspection of the victim’s fall protection equipment revealed that it was not defective, such as a torn or frayed lanyard or a cracked snap-hook. It was also determined that no personal protective equipment failure had occurred such as a broken lanyard, dee ring or lifeline.

Figure 1. Warehouse Steel Framework

CAUSE OF DEATH

The cause of death listed on the death certificate was multiple organ failure due to fall from height. Other significant causes included closed head trauma.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Whenever any work is performed at an elevation where the potential for a serious or fatal fall exists, the employer should ensure that fall protection equipment is provided and used by all employees.

Discussion: The victim was working 28 feet above the ground in an area where the potential for a fall existed. The Code of Federal Regulations (29 CFR 1926.28 (a)) states that “the employer is responsible for requiring the wearing of appropriate personal protective equipment in all operations where there is an exposure to hazardous conditions.” When the traditional safety belt/lanyard combination is impractical, an alternate form of fall protection such as safety nets (as specified in 29 CFR 1926.105) should be used. It is unclear why the victim was not attached to the lifeline at the time of the fall, but if a safety net had been in place this fatality may have been prevented.

Recommendation #2: Employers should design, develop, and implement a comprehensive safety program.

Discussion: Employers should ensure that all employees are trained to recognize and avoid hazardous work conditions. A comprehensive safety program should address all aspects of safety related to specific tasks that employees are required to perform. OSHA Standard 1926.21 (b) (2) requires employers to “instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” Safety rules, regulations, and procedures should include the recognition and elimination of hazards associated with tasks performed by employees.

REFERENCES

1. Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR Part 1926.21 (b) (2), 29 CFR 1926.28 (a) and 29 CFR 1926.105 (a) U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., July 1, 1993.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.