Farmer Dies After Tractor He was Driving Tipped Over Backward

MN FACE Investigation 95MN06101

DATE: January 2, 1996

SUMMARY

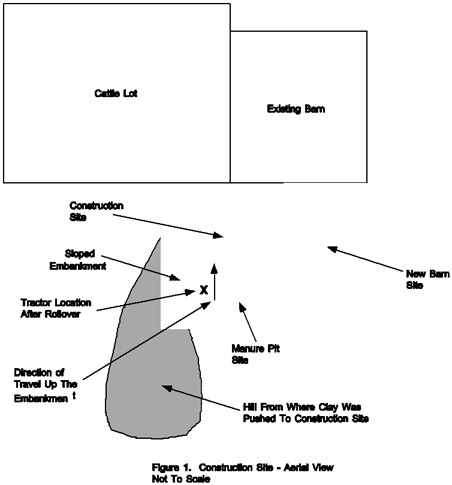

A 64-year-old male farmer (victim) died of injuries sustained when the tractor he was driving tipped over backward. The victim used a two-wheel drive farm tractor to pack soil at a farm construction site. The tractor was not equipped with a rollover protective structure or a general purpose enclosed cab. Prior to construction of a barn and a manure pit, workers from a local excavation company moved clay from a nearby hill to the construction site. After clay was spread over the site in layers approximately six inches thick, the victim used a farm tractor to compact each layer of clay. The site grade was raised approximately four feet and resulted in an embankment with a steep slope. After the level surface area had been compacted, the victim began to compact the embankment by repeatedly driving the tractor down and backing it up the embankment.

A few minutes before the incident, with the tractor at the bottom of the embankment, the victim turned it around and began driving up and backing down the embankment. He traversed the sloped area in this manner several times as he continued to compact the embankment. While he drove up the embankment, the front wheels of the tractor raised off of the ground and it tipped over backward. It came to rest upside down and pinned the victim beneath the tractor seat and the steering wheel. The operator of a caterpillar being used to move the clay immediately noticed the overturned tractor and ran to the scene but was unable to aid the victim. He went to the farm house and requested that emergency personnel be called to the scene. Emergency personnel arrived at the scene shortly after they were notified, removed the tractor from the victim and pronounced him dead at the scene. MN FACE investigators concluded that to reduce the likelihood of similar occurrences, the following guidelines should be followed:

- all tractors should be equipped with a rollover protective structure and a seat belt; and

- operators of tractors should only back up or drive down inclined grades.

INTRODUCTION

On October 23, 1995, MN FACE investigators were notified of a farm work-related fatality that occurred on October 20, 1995. The county sheriff’s department was contacted and releasable information obtained. Information obtained included a copy of their report and copies of their photos of the incident site. A witness to the incident was interviewed by a MN FACE investigator on December 5, 1995. A farm site investigation was not conducted by a MN FACE investigator.

INVESTIGATION

The victim used a two-wheel drive farm tractor to pack clay soil at a farm construction site. The tractor was approximately 30 years old and was not equipped with a rollover protective structure or a general purpose enclosed cab. It had a wide front wheel configuration and did not have dual wheels on either rear axle. The tractor did not have any counterweights mounted on it.

The incident site was adjacent to several existing dairy barns. A new dairy barn and an outside ground level concrete manure pit were going to be built at the site. The manure pit was designed to be 40 feet wide and 80 feet long and to have a concrete floor and vertical concrete walls on three sides. It was designed with a sloping floor and a depth that varied from zero feet or ground level at the end of the pit nearest to the new barn, to a depth of 8 feet at the end 80 feet from the barn.

Prior to construction of the barn and the manure pit, workers from a local excavation company prepared the site for the actual construction. The excavation work consisted primarily of moving clay from a nearby hill to the construction site. The clay was used to raise the natural grade or ground level where the new barn was being built to the same level as the floor of a nearby existing barn. Clay was also used to create the preliminary retaining walls for the manure pit that was planned for construction adjacent to the new barn. Soil and ground conditions at the site were dry at the time of the incident.

The operator of a caterpillar equipped with a blade pushed clay from a nearby hill to the construction site. After the clay was pushed to and spread over the site in layers approximately six to eight inches thick, the victim used the farm tractor to compact the clay. This procedure was done in a large area (Figure 1.) that included both the location of the new barn and an area, over 80 feet long, along one of the sides of the manure pit. The grade had been raised approximately four feet and resulted in an embankment with a slope, into the manure pit, of 45 degrees or 100 percent. After the level surface area had been compacted, the victim began to compact the embankment with the tractor. This was done by driving the tractor from the upper level down the embankment and into the area that would eventually become the floor of the pit. After reaching the floor of the pit, the victim backed the tractor up the embankment until it was completely on top of the raised grade level. This operation of driving down and backing up the embankment was repeated until nearly the entire embankment was compacted.

A few minutes before the incident, with the tractor at the bottom of the embankment, the victim turned it around and began driving up and backing down the embankment. He traversed the sloped area in this manner several times as he continued to compact the embankment. While he drove up the embankment and at a point where the rear tractor tires were approximately halfway up the embankment, the front wheels of the tractor raised off of the ground and it tipped over backward. The tractor came to rest upside down at the bottom of the embankment and pinned the victim beneath the tractor seat and the steering wheel. The operator of the caterpillar immediately noticed the overturned tractor and ran to the scene but was unable to aid or remove the victim. He went to the farm house and requested that emergency personnel be called to the scene. Emergency medical personnel arrived at the scene shortly after they were notified, removed the tractor from the victim and pronounced him dead at the scene.

CAUSE OF DEATH

The cause of death listed on the death certificate was massive crush injuries to head and chest.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: All tractors should be equipped with a rollover protective structure and a seat belt.

Discussion: Preventing death and serious injury to tractor operators during tractor rollovers requires the use of a rollover protective structure and a seat belt. These structures, either a roll-bar frame or an enclosed roll-protective cab, are designed to withstand the dynamic forces acting on them during a rollover. In addition, seat belt use is necessary to ensure that the operator remains within the “zone of protection” provided by the rollover protective structure. Government regulations require that all tractors built after October 25, 1976, and used by employees of a farm owner must be equipped with a rollover protective structure and a seat belt. Many older tractors are in use on family farms and do not have, nor are they required by government regulation to have, such structures to protect their operators in case of a rollover. All older tractors should be fitted with a properly designed, manufactured, and installed rollover protective structure and seat belt. If the tractor involved in this incident had been fitted with a rollover protective structure and a seat belt, and the seat belt had been in use, this fatality might have been prevented.

Recommendation #2: Operators of tractors should only back up or drive down inclined grades.

Discussion: Tractors should be backed up or driven down inclined grades to reduce the potential of the tractor tipping over. Although the potential of tipping over is not completely eliminated,in this position, a tractor is more stable than when it is driven up or backed down an incline. The tractor engine applies a twisting force or torque through the transmission to the rear axles of the tractor. When a tractor is driven forward, the torque applied to the axles causes the axles and wheels to rotate and the tractor moves forward. If the rotation of the wheels is restrained in any way, torque from the engine will raise the front wheels off the ground and rotate the tractor backward around the axle. On level terrain, the amount of rotation necessary to tip a tractor over backwards is greater than when a tractor is being driven up inclined terrain. When driven up inclined terrain the front wheels are naturally higher than the rear wheels, relative to a horizontal position, even when the front wheels are touching the ground. The higher the front wheels are relative to the rear wheels, whether due to driving up an incline or due to torque and rotation of the tractor around the rear axle, the more susceptible it is to tipping over backward. If the tractor had only been backed up or driven forward down the embankment, this fatality might have been prevented.

REFERENCES

1. Office of the Federal Register: Code of Federal Regulations, Labor, 29 CFR Part 1928.51 (b), U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., April 25, 1975.

2. Agriculture Safety, Fundamentals of Machine Operation, 1987, Deere & Company, Moline, Illinois, Third Edition.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.