Worker Dies After Being Run Over by a Digger Derrick Truck

Minnesota FACE Investigation 93MN008

September 2, 1993

SUMMARY

A 23-year-old male apprentice lineman (victim) died of injuries he received after being run over by the tandem dual rear tires of a digger derrick truck. The construction company the victim worked for had been sub-contracted to frame and set new electrical poles along a two-mile stretch of paved county road. He was part of a five-person crew that had been working on the job for three days. At the time of the incident, the victim and two other crew members had just finished setting and back-filling around a utility pole. They proceeded to the next pole requiring framing and setting, walking 30 feet ahead of the digger derrick in one lane of the road. The digger derrick moved slowly in reverse to the same pole. At a point approximately midway between the two poles, the victim knelt with his back to the truck to apparently inscribe a word or initials into some seal coating on the roadway. The other two crew members had walked ahead and did not see the truck approaching him. He was hit and run over by the backing truck’s passenger side tandem dual rear tires. He died on site of his injuries. MN FACE investigators concluded that, in order to prevent similar occurrences, employers should:

- consider equipping vehicles with additional mirrors to help eliminate the blind spot behind vehicles or utilize infrared or ultrasonic devices to detect the presence of objects behind the vehicle;

- consider equipping vehicles with audible back-up alarms; and

- consider implementing a safety policy which assigns one person per site the responsibility for directing vehicles and specifies site locations for non-directing pedestrian personnel.

INTRODUCTION

MN FACE was notified of a July 22, 1993, fatal construction incident on July 26, 1993. The MN OSHA and county sheriff’s reports of the incident were requested. The county coroner was interviewed via telephone. An interview with the construction company’s safety director and a site investigation was conducted on July 28, 1993.

The victim worked for a construction company employing 16 workers. The company had been sub-contracted to frame and set new three-phase electrical poles along a county highway. A company safety program, including on-the-job worker training, was in place. Safety videos and manuals were also available to workers. The victim had worked for the company, doing similar jobs, for just over one year at the time of the incident.

INVESTIGATION

A five-person work crew was framing and setting new electrical poles on a two-mile stretch of county highway in preparation for up-grading the single-phase electrical line along that stretch to three-phase. Framing the poles included installation of a cross arm and the necessary hardware on each pole for the three-phase operation; setting the poles included digging a hole and installing the new pole in it. A tandem axle digger derrick truck with an attached boom was used for hole digging and pole stabilization during the setting operation. The crew had been on site for three days, and several poles had already been framed and set.

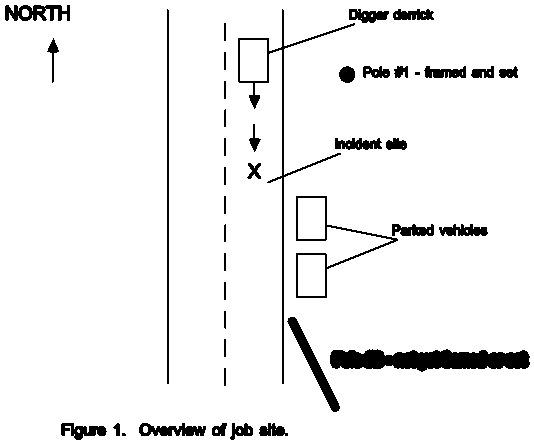

The incident occurred on a two-lane, north-south bound road. The workers were framing and/or setting poles on the east side of the road. See Figure 1 for an overview of the work site. The crew, forgetting to don their high-visibility vests, began work after lunch by setting the already framed Pole #1 with the digger derrick. They had initially by-passed Pole #2 because they did not have all of the necessary equipment for framing and setting it at the time they began work. Two company vehicles were parked on the shoulder of the road about mid-way between the poles in the north-bound lane. Seal coating, a soft tar substance, had been used to repair cracks at several locations on the roadway.

After finishing with back-filling around the newly set Pole #1, the crew members walked south in the north bound lane to Pole #2. They were about 30 feet in front of the digger derrick, which was proceeding in reverse to the same pole. The truck was moving about 2 miles per hour. It was customary for workers to direct a backing truck and any oncoming traffic in this manner.

Approximately mid-way to Pole #2, with his coworkers a bit ahead of him, the victim knelt with his back to the truck to apparently inscribe a word or initials into some soft seal coating with a plumb bob he was carrying. The truck driver, not seeing the victim in his blind spot, continued backing. The victim was hit and run over by both sets of tandem dual rear tires on the passenger side of the truck before it could be stopped. Coworkers discovered two capital letters in seal coating where the victim was run over after the incident.

The victim was pulled from beneath the truck and CPR was immediately initiated by coworkers. A 911 call was placed from a cellular phone. First responders arrived on the scene within five minutes, but the victim had died from his injuries.

CAUSE OF DEATH

The cause of death reported by the county coroner’s office was multiple traumatic injuries.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Consider equipping vehicles with additional mirrors to help eliminate the blind spot behind vehicles or utilize infrared or ultrasonic devices to detect the presence of objects behind vehicles.

Discussion: The truck involved in this incident was equipped with rear view mirrors on each side of the cab. Even if he had been wearing a high-visibility vest, the victim behind the truck was not visible to the driver. Additional mirrors could be mounted on the left rear corner of vehicles to provide the driver with a view across the rear of the vehicle while backing up. Additionally, devices are available which are capable of sensing objects through ultrasonic or infrared signals within the vehicle’s path. These devices, though not commonly used on construction vehicles, have been used successfully on other utility vehicles and may increase safety for pedestrians exposed to the hazards of backing vehicles.

Recommendation #2: Consider equipping vehicles with audible back-up alarms.

Discussion: Evidently the victim did not realize how close the backing truck was and/or how quickly it would reach him. Traffic on the county highway where the incident occurred was very light, and no other construction equipment was in operation. Audible back-up alarms, especially in circumstances like those that existed, may be useful in warning workers of approaching backing vehicles. An alarm on a backing vehicle, becoming louder as it gets closer, may increase worker awareness of their position in relation to it.

Recommendation #3: Consider implementing a safety policy which assigns one person per site the responsibility for directing vehicles and specifies site locations for non-directing pedestrian personnel. This recommendation is in accordance with 29 CFR 1926.601(b)(4)(ii).

Discussion: Under light traffic conditions like those that existed at the incident site, one person could be assigned responsibility for directing backing trucks and oncoming traffic. Since it is likely that oncoming drivers can more readily see and avoid workers than the drivers who are backing trucks, it is especially important that the person not turn his or her back to them. A company policy assigning responsibility for directing traffic to one individual on a work site and specifying appropriate work practices may be helpful in exposing fewer workers to hazards of backing vehicles. In addition, safe locations for non-directing site workers during vehicle back-up (i.e., in the view of the truck driver) could be part of such a policy.

REFERENCES

1. NIOSH – Division of Safety Research, FACE Report 92-31, Morgantown, West Virginia, March 23, 1993.

2. Minnesota Department of Health – Chronic Disease and Environmental Epidemiology Section, MN FACE Report MN9207, Minneapolis, Minnesota, October 7, 1992.

3. Office of the Federal Register, Code of Federal Regulations, Labor, 29 CFR Part 1926.601(b)(4)(ii), U.S. Department of Labor, Occupational Safety and Health Administration, Washington, D.C., July 1, 1992.

To contact Minnesota State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.