12-Year-Old Farm Boy Dies While Hitching Up Hay Wagon

Iowa Case Report: 04IA017

Report Date: June 19, 2005

Summary

In early summer 2004, a 12-year-old boy was killed while helping a farmer, his uncle, hitch a hay wagon to a truck. They had been baling hay the day before and, next morning, were preparing to unload the hay bales from the hay wagon/hayrack, which was parked in the farmyard (Photo 1). The farmer was driving a 1-ton flatbed truck, which he had just backed up to the front of the hay wagon. The boy jumped out of the truck to hitch up the wagon, and when he lifted the tongue on the wagon, the wagon apparently started to slowly roll forward toward the truck. The boy failed to get the tongue hitched to the rear of the truck, and the wagon continued its slow forward roll, pinching the boy’s head between the wagon and the rear of the truck’s metal bed. The farmer, sitting in the driver’s seat of the truck, felt nothing unusual. Suddenly, not seeing the boy, he jumped out and ran back to find him slumped over the tongue of the wagon, and a large pool of blood on the ground. The boy was dead at the scene. The tongue of the wagon had bulldozed into the ground, indicating that the wagon had moved forward (Photo 2).

|

|

Photo 1 – Side view of the loaded hay wagon at rest on nearly flat ground in the farmyard.

|

Recommendations based on our investigation are as follows:

- Farm wagons without parking brakes should always have their wheels chocked to prevent them from rolling, especially when parked on rolling or sloping ground.

- When hitching wagons to towing vehicles, farmers and farm workers should stand safely to one side, out of the hitching area, where they can see the hitch and communicate directions to the vehicle operator.

- Manufacturers of farm wagon running gear and other wagons should consider providing parking brakes, chocks, or other reliable means to secure wagons when they are parked.

Introduction

During the summer of 2004, a 12-year-old farm boy was working for his uncle when he was crushed between a hay wagon and a truck bed. The Iowa FACE program was alerted to this incident by a colleague, and an immediate investigation was begun, gathering information from newspapers, the County Sheriff, and the State Medical Examiner’s Office. Contact was made with the farmer who owned the farm. However, a site visit was not conducted since excellent information and photographs were obtained from the county sheriff.

The uncle was a farmer who managed 700 acres (285 hectares) of land planted in corn, soybeans, and hay. He had been working and living with his family at this location for the past 25 years. The boy was one of several neighbor boys who had worked at the man’s farm over the past several years. On the day of this incident, the farmer was also working with a neighbor and another 16-year-old boy, for a total work crew of four, baling hay early in the summer.

There was no official safety program or written policies for employment at this small farm. Several local farm boys were frequently hired for odd jobs on an hourly basis, and paid in cash. The farmer had significant construction experience, and he would often hire 6 or 7 boys throughout the summer to assist with various farm and related construction projects.

|

|

Photo 2 – Front view of the hay wagon, showing

the tongue, which had bulldozed into the ground as the wagon rolled forward. |

Investigation

On the day prior to this incident, the work crew of four had baled about 800 bales of hay, using a conventional square baler, which creates bales that weigh about 40-60 lbs (18-27 kg). They had baled several loads of hay and, early the next morning, were in the process of moving this hay into storage. The 12-year-old boy was big and strong for his age, and could easily handle the hay bales. Nonetheless, the farmer would move bales stacked too high for the helper, and leave the lower bales for the boy, who was earning extra money to attend the county fair.

The hay wagon was a typical wooden rack on a standard running gear with a metal tongue and clevis hitch (Photo 2). The wagon carried 100 bales of hay and was parked alone in the farmyard without brakes or wheel chocks. The edges of the hay rack bed were covered with 1½ in. angle iron (Photo 3). The farmer and boy worked approximately 30 minutes that morning before they drove to retrieve the loaded hay wagon. The farmer drove his 1-ton straight truck with flatbed box containing old pieces of plywood, a pallet, and several bags of soybean seed. The plywood stuck out beyond the truck bed about 12 inches (300 mm).

|

|

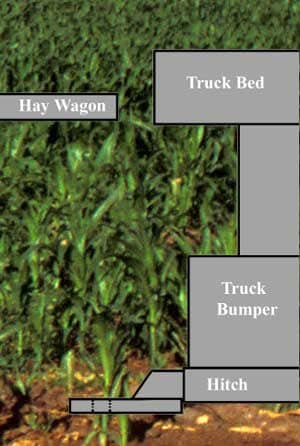

Photo 3 – View of rear of truck showing relative position of bumper and truck bed.

Hay wagon shown to the right is typical, but is not the one involved in this incident. |

The loaded hay wagon had been moved into the farm yard the day before by the farmer and his wife. The farmer remembered pulling the hitch pin himself, and seeing the tongue fall to the ground without the wagon continuing to move. This area of the farmyard was flat (Photo 1), not at all like other areas of his farm ground, which required all wagons to be blocked against rolling. There was no indication that the loaded hay wagon might roll.

The farmer backed his truck into position in front of the hay wagon and the boy jumped out to hitch up the wagon. This was a simple task he had done many times before. Looking into the side mirror, the farmer was communicating with the youth when he suddenly lost sight of him. Exact details at this point are hard for the farmer to recall, but he did not feel a collision of any kind. He immediately pulled his truck forward a few feet, then jumped out and ran behind to find the boy slumped over the tongue of the wagon, and a large pool of blood on the ground. There was approximately 4-5 feet between the vehicles at this time. According to the farmer, the boy hardly had a mark on him, but was not breathing. It was determined later that he had died instantly from a head injury. There was no damage to the truck or the hay wagon, or any signs of direct collision of the two vehicles.

Measurements taken at the scene showed the front of the loaded hay wagon at 35–36½ inches (890-930mm) above the ground, and the rear of the flat bed truck at 34¾–39 inches (880-990 mm) above the ground (Diagram 1). Given these measurements, and the description by the farmer, it is possible the hay wagon slowly rolled just close enough towards the rear of the truck, but without touching it, to fatally injure the boy as he bent over the wagon tongue to guide it toward the pickup’s hitch and drop the hitch-pin in place. Once pushed, bumped, or rocked back in the tracks into which it had settled, been pulled, or otherwise set in motion, even a slow-moving wagon can be difficult to stop.

|

|

Diagram 1 – Shows the relative positions of the

truck and hay wagon per measurements taken by Sheriff’s investigators. |

Cause of Death

The cause of death from the medical Examiner’s report was, “neurogenic shock due to acute cranial cerebral blunt force trauma due to a farm accident.”

Recommendations/Discussion

Recommendation #1: Farm wagons without parking brakes should always have their wheels chocked to prevent them from rolling, especially when parked on rolling or sloping ground.

Discussion: The farmer assumed that the area of his farmyard in Photo 1 was flat. While it appears flat in the photograph, the terrain under the wagon apparently sloped slightly away from the front of the wagon, as evidenced by the tongue, which was found dug into the dirt after the wagon had rolled (Photo 2). On ground that was obviously sloped, the farmer always used wheel chocks, but he never considered them at this location because of the flat appearance of the terrain. When the wagon was unhitched and left in position, the tongue would have dropped to the ground and dug in slightly if the wagon had continued to move from its own momentum. However, the wagon did not appear to have moved appreciably, and the farmer may have assumed it to be stable and at rest on flat ground, even though there may have been a forward push on the tongue. The direction of the forces on this wagon could have changed while the wagon sat overnight in the farmyard as the wheels settled into the ground. It is possible that, initially, the tongue was holding the wagon in place, and when the boy picked it up, the wagon began to move.

Experienced farmers in this situation would typically lean against the wagon to slow or stop it before it struck the truck, stick the tongue back in the dirt as a temporary stop, or jump out of the way if the wagon continued to roll. A less experienced 12-year-old boy may not know these techniques or be able to employ them. The seemingly simple job of hooking up a wagon evidently became a complex maneuver of trying to manage the moving tongue of the hay wagon with one hand, and working with a hitch pin in the other hand, hoping they would somehow come together with the wagon properly hitched to the truck.

Leaving farm wagons un-chocked is somewhat like parking a motor vehicle with its manual transmission in neutral without engaging the parking brake, something that is rarely done for fear the vehicle might roll away. Wheel chocks should be regular equipment for all farm wagons and other vehicles which do not have built-in parking brakes. Farmers should develop a habit of using them on a regular basis even on “flat ground”, remembering the tragic consequences evident in this case. On ground that is obviously sloped, one should block all four wheels against movement with substantial chocks or other means to guarantee the wagon will stay put.

Recommendation #2: When hitching wagons to towing vehicles, farmers and farm workers should stand safely to one side, out of the hitching area, where they can see the hitch and communicate directions to the vehicle operator.

Discussion: The routine hitching procedure requires moving the truck (or a tractor) close to the wagon, then parking and dismounting to make the connection. This task can be less difficult when the truck’s hitch or the wagon’s tongue accommodate misalignment, such as with a tractor where the tongue can be swung into place from the side of the drawbar.

In the common alternative, an assistant moves between the wagon and the truck to guide the tongue into place as the truck inches rearward, dropping the hitch pin into place to make the final coupling. This process relies on good communication between the assistant and truck driver, and complete control of the truck’s movement. To avoid repeat incidents similar to this case, the assistant should guide the driver while remaining outside of the area between the moving truck and the wagon. Once the truck is nearly to the right position, the assistant should evaluate the relative positioning, and then instruct the driver to make the final adjustments and secure the truck against movement before moving between the truck and wagon to drop the hitch pin into place. This method decreases the risk of injury from being struck by the towing vehicle. However, it does not remove the risk of being struck by an un-chocked wagon.

Recommendation #3: Manufacturers of farm wagon running gear and other wagons should consider providing parking brakes, chocks, or other reliable means to secure wagons when they are parked.

Discussion: Wagons are often disconnected from tractors and other towing vehicles on sloping terrain where, initially on unhooking, they may move forward or backward. Manufacturers of such running gear and wagons should provide means such as chocks or parking brakes to ensure they remain parked. Providing chocks and a proper, easily accessible storage location for them, would, when routinely and properly used, improve safety for farmers and farm workers.

References

- ASAE Standards. 2004. S351: Hand Signals for Use in Agriculture. St. Joseph, MICH.: American Society of Agricultural Engineers. Available at: http://www.asabe.org/external icon.

- CDC-NIOSH. Hand Signals. Atlanta, GA: Centers for Disease Control and Prevention. National Agricultural Safety Database (NASD). Available at: http://www.nasdonline.org/index.htmlexternal icon. (Link updated 8/5/2009)

- AEM. 2005. Agricultural Tractor Safety Manual. Milwaukee, WI: Association of Equipment Manufacturers. Available at: http://shop.aem.org/default.aspxexternal icon. (Link updated 4/8/2013)

Iowa FACE Program

Fatality Assessment and Control Evaluation, FACE, is a program of the National Institute for Occupational Safety and Health (NIOSH), which is part of the Centers for Disease Control and Prevention of the U.S. Department of Health and Human Services. Nationally, the FACE program identifies traumatic deaths at work, conducts in-depth studies of select work deaths, makes recommendations for prevention, and publishes reports and alerts. The goal is to prevent occupational fatalities across the nation.

The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE case surveillance and evaluation program and also funds state-based programs in several cooperating states. In Iowa, The University of Iowa through its Injury Prevention Research Center works in conjunction with the Iowa Department of Public Health and its Office of the State Medical Examiner to conduct the Iowa FACE program.

Nationally, NIOSH combines its internal information with that from cooperating states to provide information in a variety of forms which is disseminated widely among the industries involved. NIOSH publications are available on the web at https://www.cdc.gov/NIOSH/FACE/ and from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE also publishes its case studies, issues precautionary messages, and prepares articles for trade and professional publication. In addition to postings on the national NIOSH web site, this information is posted on the Iowa FACE site. Copies of FACE case studies and other publications are available by contacting Iowa FACE, too.

The Iowa FACE team consists of the following specialists from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; John Lundell, MA, Co-Investigator; Murray Madsen, MBA, Chief Trauma Investigator; and Co-Investigator/specialists Risto Rautiainen, PhD, and Wayne Sanderson, PhD, CIH. Additional expertise from the Iowa Department of Public Health includes Rita Gergely, Principal Investigator, and John Kraemer, PA, from the Office of the State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.