A Solar Panel Installer Dies When He Falls Off a Roof

California Case Report: 10CA003

Summary

A solar panel installer died when he fell off a three-story apartment building roof. The victim was checking the alignment of solar panel brackets and was walking backwards when he stepped off the edge of the roof. He fell 45 feet to the concrete sidewalk below. The pre-project plan stated that fall protection would be required on the job, however, the employees were not wearing any fall protection. The CA/FACE investigator determined that in order to prevent future incidents, employers who install solar panels on roofs should ensure that:

- Employees wear fall protection when working on sloped roofs with identified fall hazards.

- Worksite safety procedures and practices for fall protection are developed and implemented.

Introduction

On Wednesday April 7, 2010, at approximately 11:30 a.m., a 30-year-old solar panel installer fell 45 feet off a pitched roof to the concrete sidewalk below. The CA/FACE investigator received notification of this incident from the April 16, 2010 issue of the Cal-OSHA Reporter (a commercial publication about workplace health and safety). On June 3, 2010, the CA/FACE investigator interviewed the victim’s supervisor, co-worker and two managers representing the employer. The CA/FACE investigator also visited the incident scene and interviewed four apartment residents who witnessed the incident.

The employer of the victim was a multi-state full-service solar provider for homeowners, businesses, and government organizations. The company has been in business for four years and has approximately 650 employees. The satellite office where the victim worked had 30 employees. There were six employees at the apartment complex the day of the incident.

The victim was born in the United States. He was a high school graduate and had worked for this solar company for six months. The victim had worked in the roofing construction industry for several years, but had no prior experience in solar panel installation.

The solar company had an Injury and Illness Prevention Program (IIPP) that included management and employee responsibilities, safety meetings, training, and incentive and disciplinary measures. The communication section of the IIPP incorporated guidance on the use of pre-project plans and job hazard analysis to identify and evaluate workplace hazards.

The company’s training program consisted of documented new employee orientation, specific on-the-job training (OJT), jobsite orientation, and weekly safety meetings. The victim had undergone employee orientation and was receiving OJT as a junior solar panel installer.

Investigation

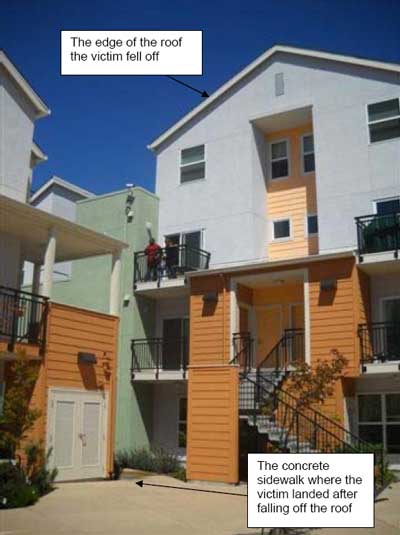

The location of the incident was a housing unit with multiple three-story apartment buildings. Solar panels were being installed on the sloped roofs of the apartment buildings. On the unit where the incident occurred, access to the roof was gained by a stairwell up to a third floor landing and then a straight ladder from the landing to the bottom of the sloped roof. The distance from the bottom of the sloped roof to the landing was approximately eight feet. The distance from the sides of the sloped roof to the ground below was approximately 45 feet. The slope of the roof was approximately 9:12 or 37 degrees.

A project pre-plan was completed for the job which stated that fall protection would be required when working on the sloped roofs. A safety meeting was held on the first day of the job by the project manager who informed all work crews that fall protection would be required when working on the roofs.

On the day of the incident, the victim along with his supervisor and co-worker were on the sloped roof checking the alignment of the brackets for the support structure of the solar panels. This was their second day on the job. The victim was working within four to five feet of the roof edge and was probably walking backwards as he performed this task. Neither the work crew nor the victim were wearing fall protective equipment and was tied off, and there were no guard rails or safety nets in place. The co-worker and supervisor heard the victim say something, and then looked over at the spot where they last saw the victim. By that point, the victim had fallen over the edge of the roof onto to the concrete sidewalk below. The co-worker immediately called 911. The fire department and paramedics arrived at the location within minutes of the call. The victim was air lifted to the hospital where he was pronounced dead.

Cause of Death

The cause of death according to the death certificate was blunt force head trauma and abdominal injury.

Recommendations/Discussion

Employers who install solar panels on roofs should ensure that:

Recommendation #1: Employees wear fall protection when working on sloped roofs with identified fall hazards.

Discussion: In this incident, the victim and his co-workers were working on a sloped roof with identified fall hazards. The roof had a slope of approximately 37 degrees and was 45 feet off the ground which presented a risk of serious injury and/or death in the event of a fall. The victim was not wearing any type of fall protection. As he was walking backwards on the roof to check the alignment of the solar panel brackets, he stepped off the roof and fell to the ground below.

Fall protection should be worn by employees on sloped roofs greater than 30 degrees, or whose work exposes them to a risk of a fall in excess of 7 ½ feet. The two types of fall protection systems commonly used on roofs are a personal fall restraint (PFR) system and a personal fall arrest (PFA) system. A PFR system is used to prevent an employee from falling. It consists of anchorages, connectors, lanyards, and body harness. A PFA system is used to stop an employee during a fall from a working level. This system consists of an anchorage, connectors, a deceleration device, and a body harness. Had the victim been wearing the required fall protection, his death would have been prevented.

Recommendation #2: Worksite safety procedures and practices for fall protection are developed and implemented.

Discussion: In this incident, the employer had developed safety procedures and practices for fall protection. The hazard analysis for the job identified the sloped roof as a fall hazard and described the fall protection plan for the employees to mitigate the hazard in their project pre-plan. The fall protection plan included 100% tie off on the sloped roof with single-D anchors, yo-yo type fall restraint life line, and full-body harness. The work crews assigned to this job were informed of this safety requirement on the first day of the job by the project manager. When the work crews arrived at the jobsite and gained access to the roof, none of these safety procedures were implemented. The crew supervisor used his discretion and did not require the use of fall protection for himself and his two co-workers. He assumed that since the solar panels were being installed within the center of the roof and not close to the edges that fall protection was not necessary. It is not known how often management evaluated individual job team compliance with fall protection at the worksite.

There are many methods to implement safety procedures and practices for fall protection. A project pre-plan could include a signature page which all employees on a job have to sign prior to commencing with the work. The signature page would verify that all affected employees are aware of their safety responsibilities and also would give them the opportunity to ask questions and clarify any misunderstandings. Initial and periodic safety inspections and audits of the workplace can be performed by management personnel to ensure that job site supervisors identify safety hazards or unsafe acts as they occur so that corrective action can be taken immediately. Corrective action might include a form of discipline for unsafe acts or behavior, as well as recognition or reward for safe acts and behavior. Had these methods been used at this jobsite, the employees would most likely have worn the required fall protection and this incident would have been avoided. Employers can enhance worker compliance with safe work practices through programs of task specific training, supervision, recognition, and progressive disciplinary measures.

Reference

- Division of Occupational Safety and Health – Title 8 regulations

Subchapter 7 – General Industry Safety Orders

Group 1. General Physical Conditions and Structures Orders

Article 2. Standard Specifications, §3212. Floor Openings, Floor Holes and Roofs.

Article 6. Powered Platforms and Equipment for Building Maintenance, §3294. Powered Platform Installations–Affected Parts of Buildings. (c) Roof guarding (6)

Group 2. Safe Practices and Personal Protection.

Article 10. Personal Safety Devices and Safeguards. §3380. Personal Protective Devices. - Subchapter 4. Construction Safety Orders

Article 3. General §1511. General Safety Precautions. §1509. Injury and Illness Prevention Program. §1514. Personal Protective Devices.

Article 24. Fall Protection. §1669. General. §1670. Personal Fall Arrest Systems, Personal Fall Restraint Systems and Positioning Devices. §1671. Safety Nets. §1671.1. Fall Protection Plan. §1671.2. Controlled Access Zones and Safety Monitoring Systems.

Article 30. Roofing Operations and Equipment §1724. Roofing–General. (f) Personal Fall Protection. §1730. Roof Hazards. §1731. Roof Hazards – New Production-Type Residential Construction.

Exhibits

|

|

|

|

3. The three-story apartment building involved in the incident.

|

California Fatality Assessment and Control Evaluation (FACE) Project

The California Department of Public Health, in cooperation with the Public Health Institute and the National Institute for Occupational Safety and Health (NIOSH), conducts investigations of work-related fatalities. The goal of the CA/FACE program is to prevent fatal work injuries. CA/FACE aims to achieve this goal by studying the work environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in fatal injury, and the role of management in controlling how these factors interact. NIOSH-funded, State-based FACE programs include: California, Iowa, Kentucky, Massachusetts, Michigan, New Jersey, New York, Oregon, and Washington.

To contact California State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.